Condenser miniature silicon microphone and preparative method

A silicon microphone and capacitive technology, applied in the field of micro-electro-mechanical systems, can solve the problems of complex implementation, increased processing complexity, and ineffective reduction of residual stress, etc., to reduce chip area and improve design flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

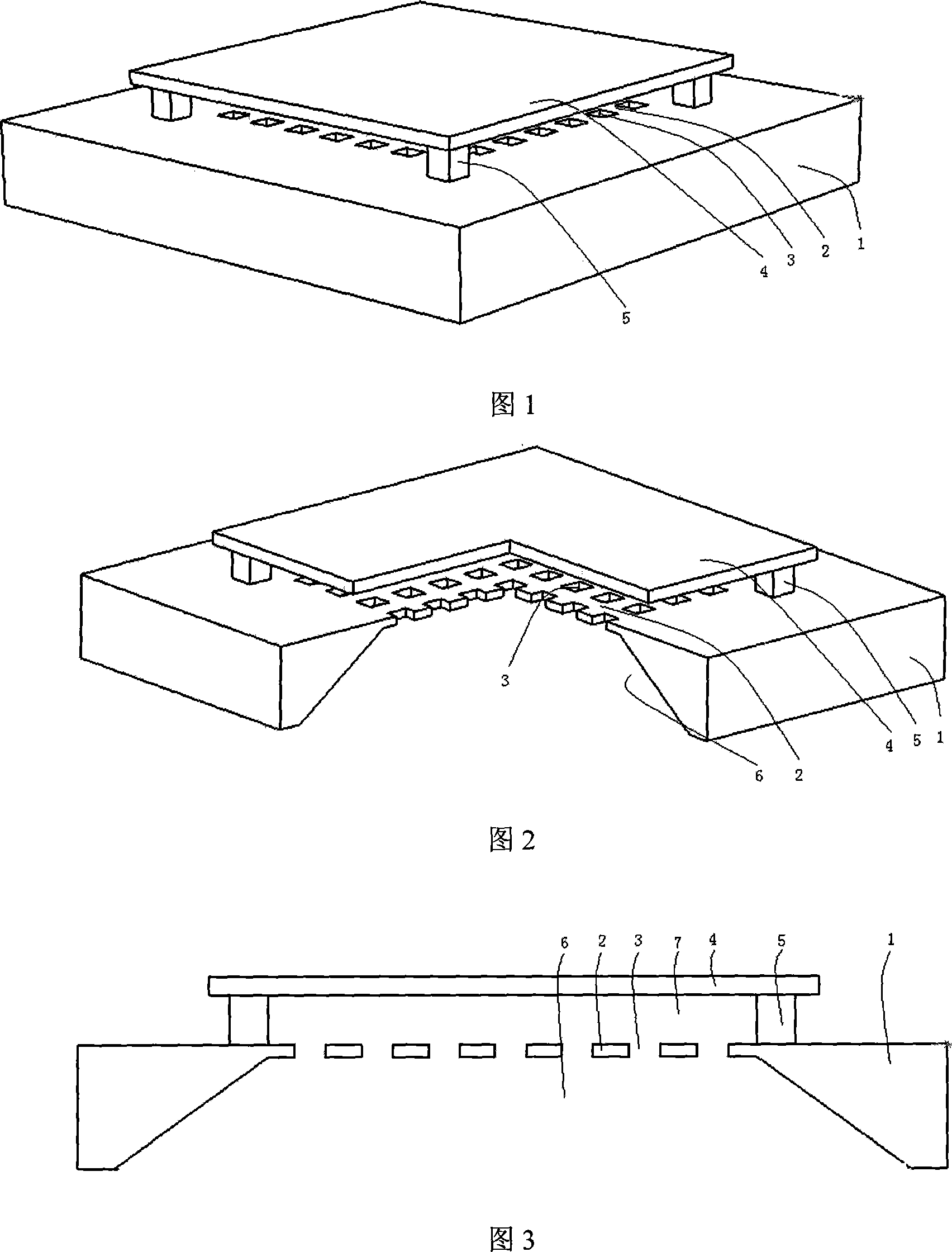

[0018] Please refer to FIG. 1 to FIG. 3 , the capacitive miniature silicon microphone of the present invention includes: a back plate, a vibrating membrane, an insulating support body, and the like.

[0019] The back plate 2 has a conductive function and is used as one pole of a capacitor. During manufacture, a back cavity 6 is first formed on a silicon substrate by an isotropic or anisotropic processing method, and then the back cavity 6 is obtained while the back cavity 6 is obtained. Combined with self-stop technology (such as heavy doping), the back plate 2 can be formed, wherein the substrate 1 can be low-resistance silicon, or glass with a metal-covered surface, which acts as a mechanical support, and then passes through the back plate 2. Multiple acoustic holes 3 can be obtained by means of selective doping or photolithography. Multiple acoustic holes 3 can play the role of propagating sound pressure and adjusting the damping between the vibrating membrane and the back p...

Embodiment approach 2

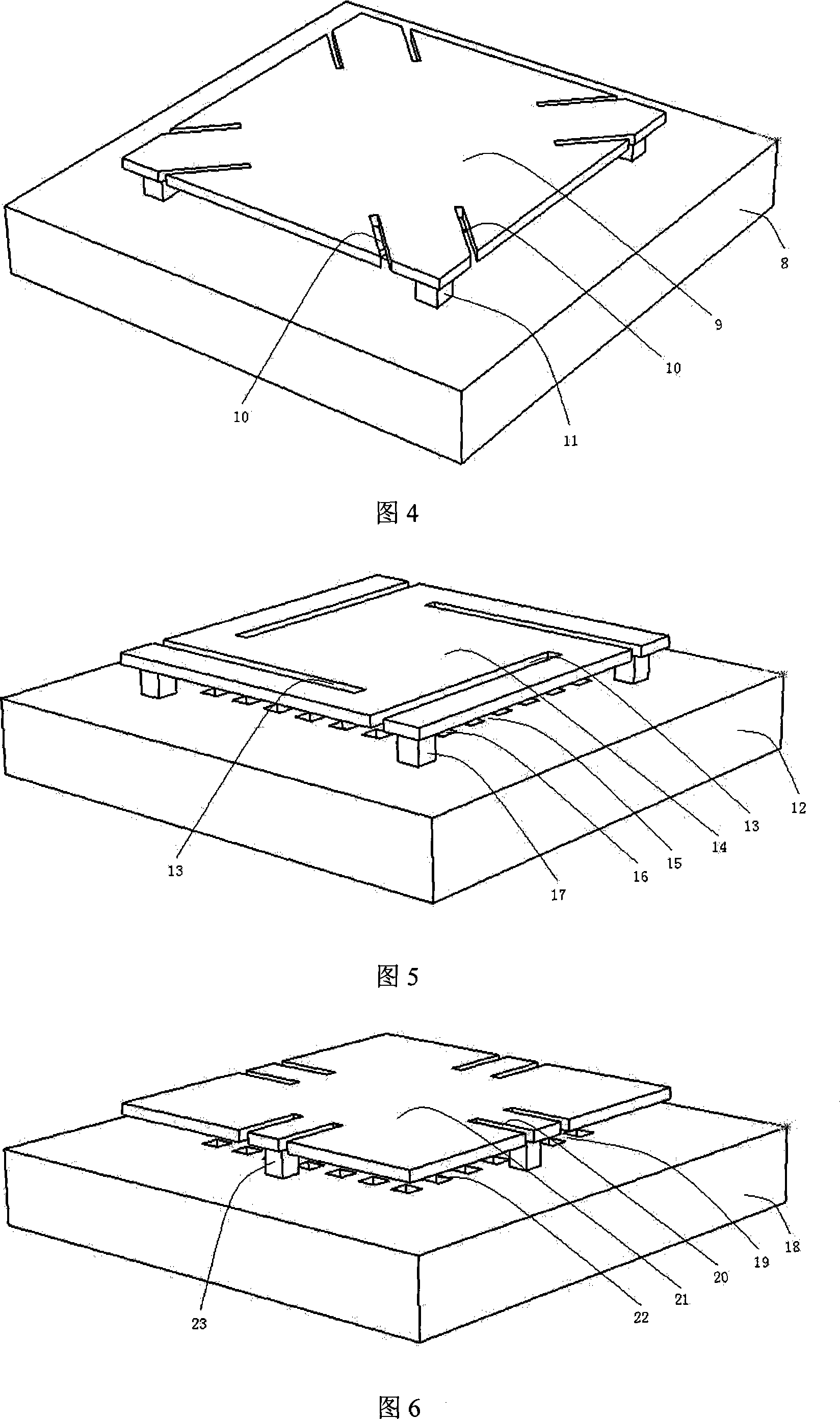

[0021] Please refer to Fig. 4, this embodiment mode is similar to embodiment mode one, and substrate 8 can be low-resistance silicon, or the glass that has metal covering surface, plays mechanical supporting role; Silicon nitride, etc., the mechanical support of the vibrating film 9 is completed by connecting the insulating support body 11, which acts as an insulating support, to the back plate at the four corners of the vibrating film. The insulating support body can be made of silicon dioxide or silicon nitride, etc. Insulation materials alone or in combination. The rest of the back plate, back cavity and sound holes are the same as in Embodiment 1.

[0022] The difference from Embodiment 1 is that there are a plurality of narrow grooves 10 on the vibrating membrane, and the plurality of narrow grooves are two parallel short slits respectively. The angle extends toward the center of the vibrating membrane, adding narrow grooves 10 can provide more design flexibility and imp...

Embodiment approach 3

[0024] Please refer to Fig. 5. This embodiment is the same as Embodiment 2 except that the shape, size, quantity and position of the grooves on the vibrating membrane are different. In this embodiment, the plurality of narrow grooves are formed by the A long slit extending from the edge of the vibrating membrane and parallel to the corresponding side of the vibrating membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com