Material with surface multilevel nano micron structure, preparation method thereof and nickel-zinc cell containing the material in anode

A nano-micron and nano-technology, applied in the field of inorganic advanced nanomaterials, can solve the problems of low capacity and poor cyclability, and achieve the effect of solving low capacity and poor cyclability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

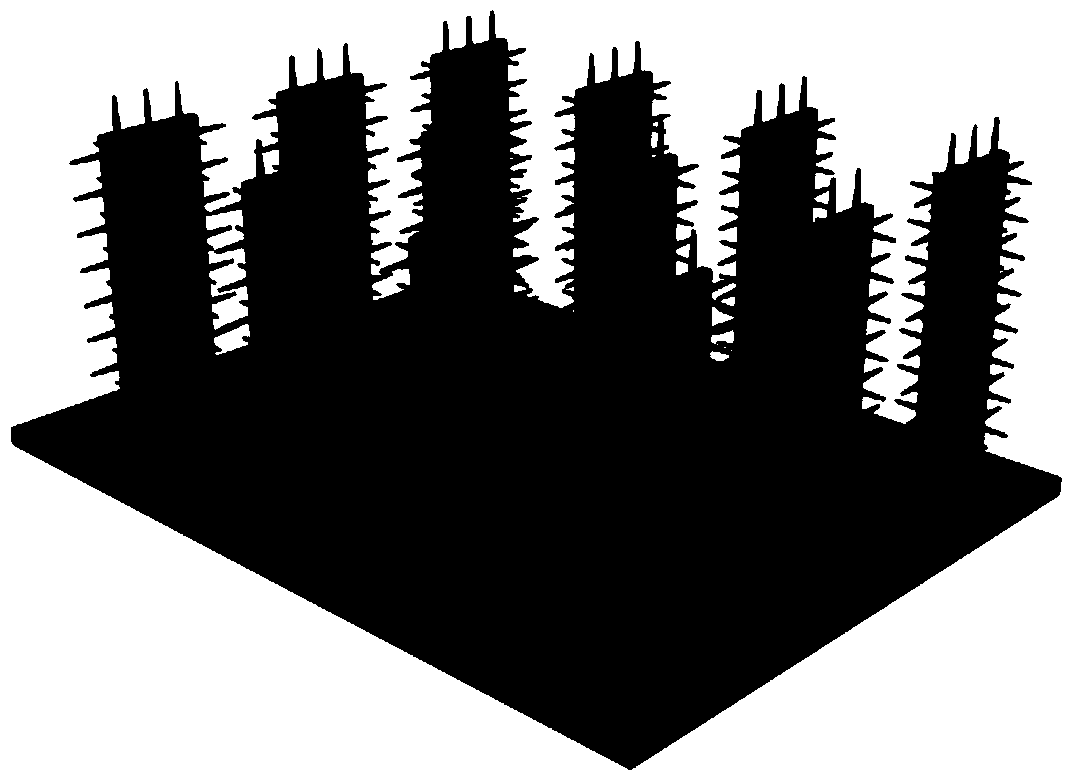

[0052] a. put the foamed nickel base into the first reactor, then add cobalt nitrate comprising 0.05 mol / liter, 0.2 mol / liter ammonium fluoride and 0.25 mol / liter urea to the reactor Aqueous solution, then close the reaction kettle, raise the temperature to 120°C and keep it under autogenous pressure for 12 hours to carry out the first hydrothermal reaction, so as to grow cobalt hydroxide primary micron line arrays on the surface of the nickel foam substrate perpendicular to the substrate;

[0053] b. take out the nickel foam substrate, wash and dry;

[0054] c. put the foamed nickel base processed in step b into the second reactor, then add the second aqueous solution comprising 0.025 mol / liter of cobalt nitrate and 0.25 mol / liter of urea in the reactor, and seal the The reaction kettle is heated to 100°C and kept under autogenous pressure for 10 hours to carry out the second hydrothermal reaction, so that each primary micron wire of cobalt hydroxide forms a rectangular micro...

Embodiment 2

[0061] Referring to the method in embodiment 1, cobalt nitrate is replaced by cobalt chloride in embodiment 1 step a and step c, nickel nitrate is replaced by nickel chloride in step e, the material that obtains and the material that embodiment 1 obtains in They are very close in appearance and performance.

Embodiment 3

[0063] Referring to the method in Example 1, the porous conductive substrate was changed from foamed nickel substrate to carbon fiber felt, and the rest remained unchanged.

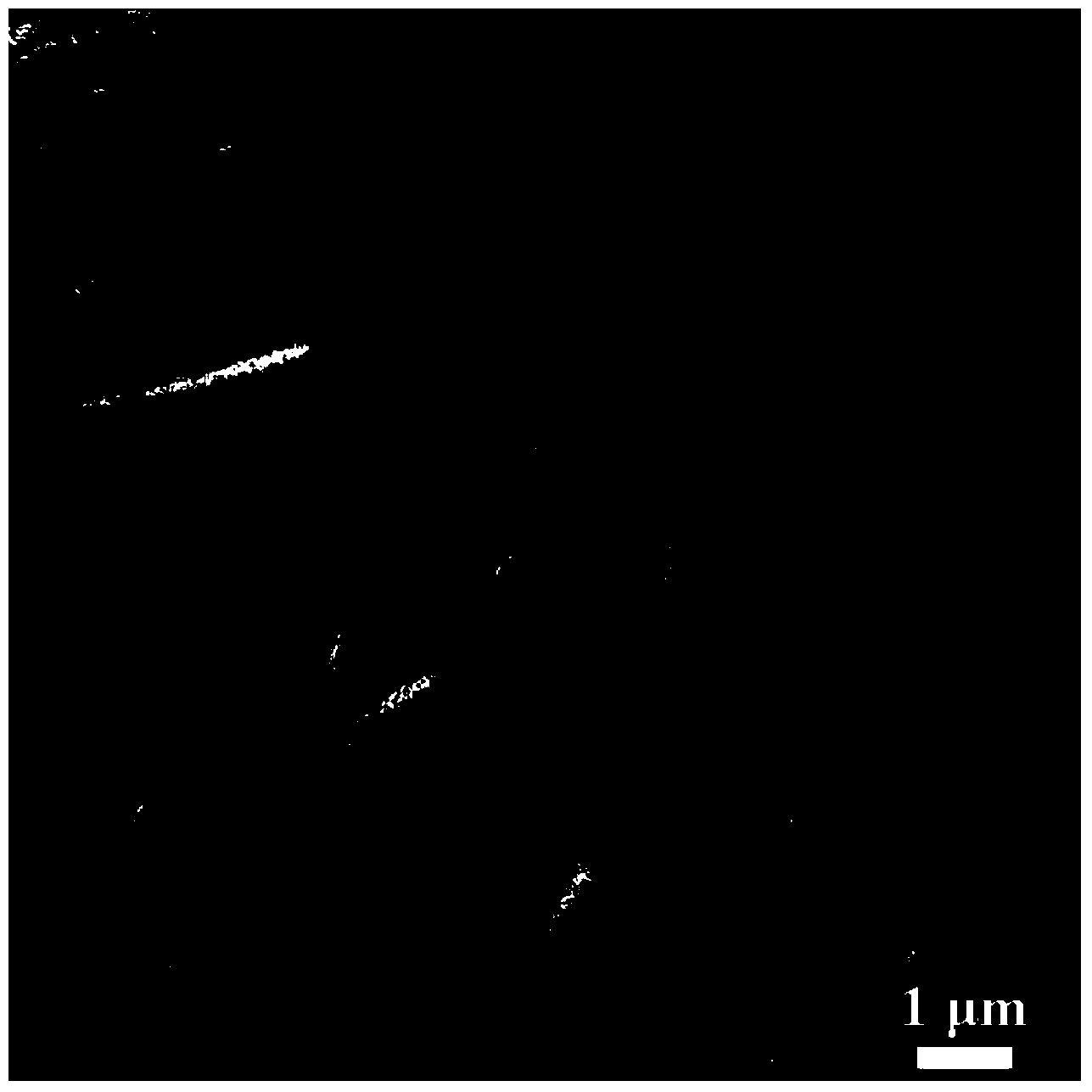

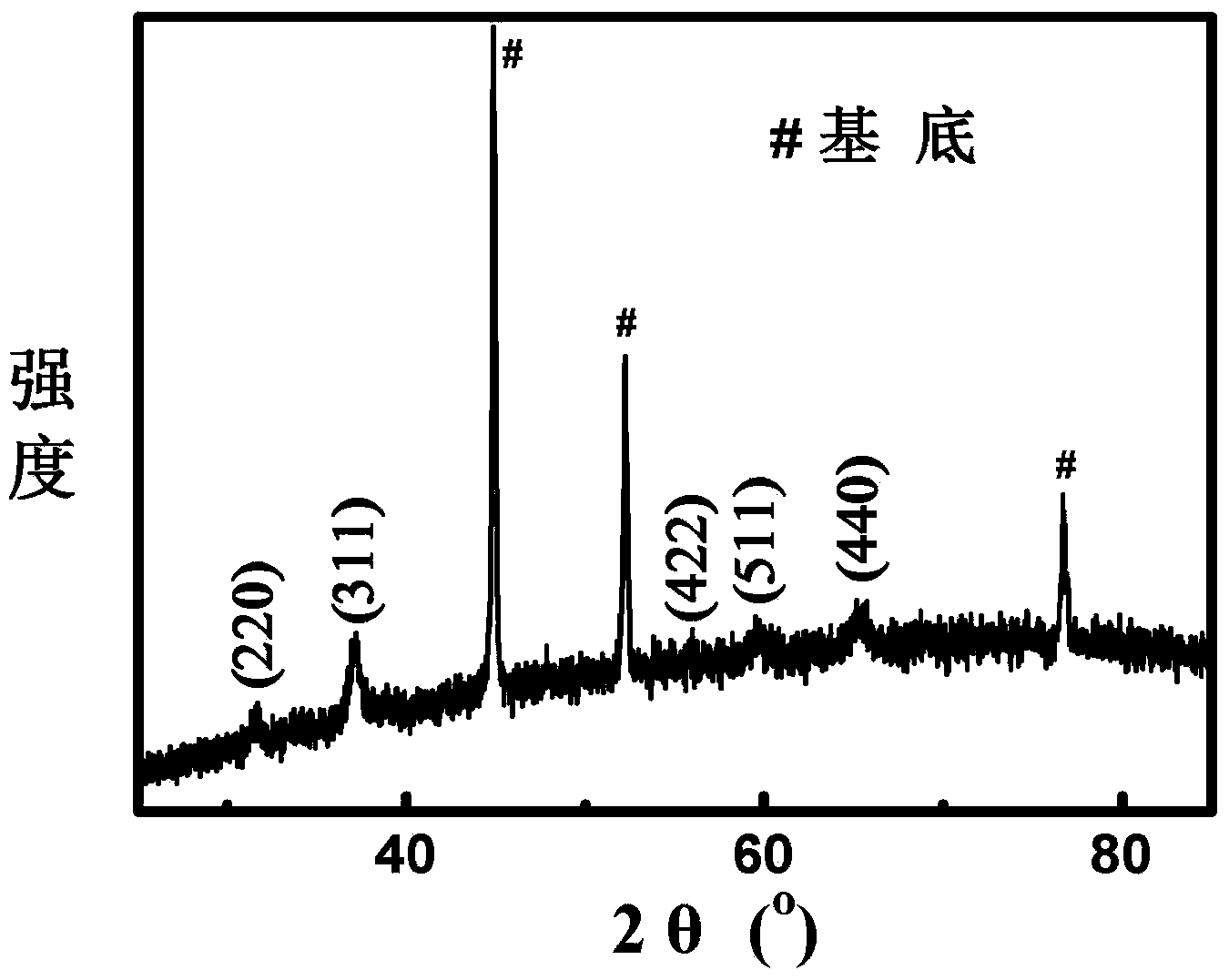

[0064] The resulting scanning electron microscope images can be found in the appendix Figure 7 , its XRD spectrum is shown in the appendix Figure 8 , and its cyclic voltammetry curve is shown in the appendix Figure 9 , and its charge-discharge curve is shown in Figure 10 , and its cycle stability diagram is shown in the appendix Figure 11 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com