Method for preparing ferrite magnetic sheet of wireless charger from waste soft-magnetic material

A wireless charger and ferrite magnetic technology, which is applied in the manufacturing of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of high cost and uneconomical, and achieve low cost, high product demand and product performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

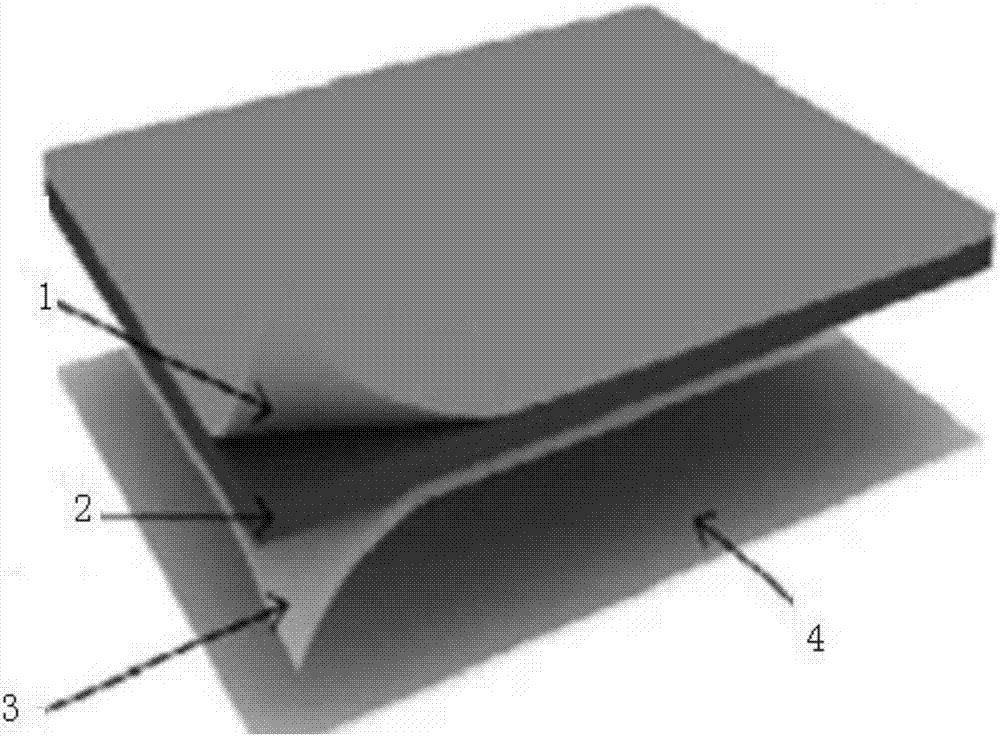

Embodiment 1

[0020] The present invention provides a method for preparing ferrite magnetic sheets for wireless chargers from soft magnetic waste materials. (1) Ingredients: the reaction materials include waste manganese zinc magnetic cores (MnZnFeO 3 )50%, SiO 2 3.0%, Bi 2 O 3 1.0%, V 2 O 5 1.0%, CuO 2.0%, ZnO 2 3.0%, scrap nickel-zinc magnetic core (NiZnFeO 3 ) 40%; reaction material: ball: water mass ratio of 1:2:1 in a ball milling tank, ball milled in a planetary ball mill at a speed of 500r / min for 4 hours, taken out in an oven at 100°C for drying, and passed through a 60 mesh sieve ; Then pre-fired in a resistance furnace at 900 ℃ for 6 hours, and then ball milled in a ball mill for 4 hours, dried, sieved, take the 60-120 mesh components, made into powder, bagged and sealed for use; (2 ) Casting pulping: all according to mass percentage of deionized water 55%, PVA 35%, PAA 0.5%, PEG 0.5%, PVB 0.5%, latex 0.5%, powder 8.0%, the above materials are mixed and placed in a ball mill tank ...

Embodiment 2

[0022] The present invention provides a method for preparing ferrite magnetic sheets for wireless chargers from soft magnetic waste materials. (1) Ingredients: the reaction materials include waste manganese zinc magnetic cores (MnZnFeO 3 ) 55%, SiO 2 1.0%, Bi 2 O 3 0.5%, V 2 O 5 0.5%, CuO 2%, ZnO 2 1.0%, nickel-zinc scrap core (NiZnFeO 3 ) 40%; reaction material: ball: water mass ratio of 1:2:1 in a ball milling tank, ball milled in a planetary ball mill at a speed of 500r / min for 4 hours, taken out in an oven at 100°C for drying, and passed through a 60 mesh sieve ; Then pre-fired in a resistance furnace at 900 ℃ for 6 hours, and then ball milled in a ball mill for 4 hours, dried, sieved, take the 60-120 mesh components, made into powder, bagged and sealed for use; (2 ) Casting pulping: all according to mass percentage of deionized water 50%, PVA 30, PAA 0.5%, PEG 0.5%, PVB 0.5%, latex 0.5%, powder 18%, the above materials are mixed and placed in a ball mill tank , Ball milli...

Embodiment 3

[0024] The present invention provides a method for preparing ferrite magnetic sheets for wireless chargers from soft magnetic waste materials. (1) Ingredients: the reaction materials include waste manganese zinc magnetic cores (MnZnFeO 3 )50%, SiO 2 1.0%~5.0%, Bi 2 O 3 1.0%, V 2 O 5 1.0%, CuO 5.0%, ZnO 2 3.0%, scrap nickel-zinc magnetic core (NiZnFeO 3 ) 35%; reaction material: ball: water mass ratio of 1:2:1 in a ball mill tank, ball milled in a planetary ball mill at a speed of 500r / min for 4 hours, taken out in an oven at 100°C for drying, and passed through a 60 mesh sieve ; Then pre-fired in a resistance furnace at 900 ℃ for 6 hours, and then ball milled in a ball mill for 4 hours, dried, sieved, take the 60-120 mesh components, made into powder, bagged and sealed for use; (2 ) Casting pulping: all according to mass percentage of deionized water 50%, PVA 30, PAA 0.5%, PEG 0.5%, PVB 0.5%, latex 0.5%, powder 18%, the above materials are mixed and placed in a ball mill tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com