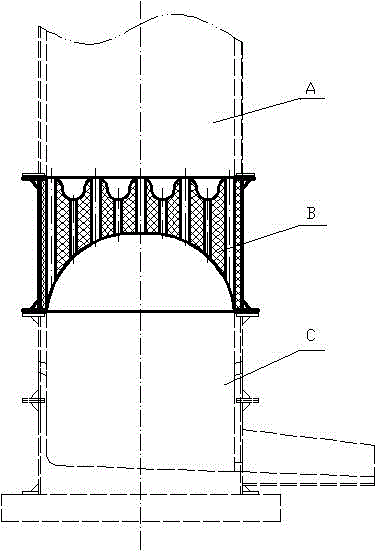

Integral cellular fire-resistant hearth for fuel gas cupola furnace

A cupola and refractory furnace technology, applied in the field of cast iron smelting, can solve problems such as cumbersome operation, burnout of the grate, and increased production costs, and achieve the effects of saving water resources, increasing the furnace temperature, and improving work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

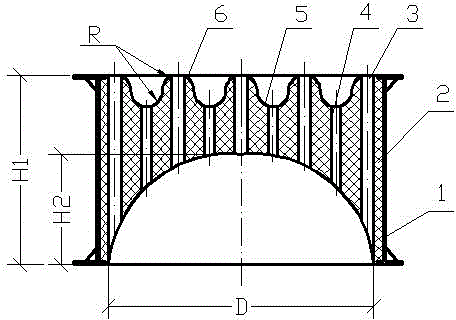

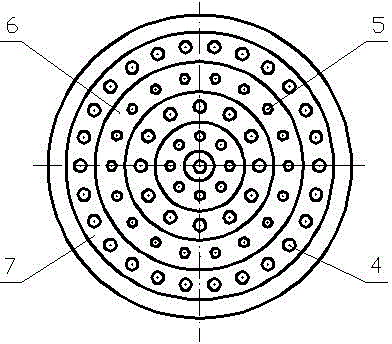

[0021] An embodiment of an integral honeycomb refractory hearth for a gas cupola, replacing the water-cooled grate and refractory balls of a 2t / h gas cast iron furnace: the hearth height H1 is 600mm; the thickness of the hearth shell boiler steel plate is 6mm; the refractory castable is made of 82% neutral alumina powder and 12% silicon carbide powder are base materials, 5% pure calcium aluminate cement is a non-sintering binder, and 1% metal aluminum powder, boric acid and sodium tripolyphosphate are composite additives; The radius of the annular convex and concave groove on the upper part of the refractory bed is R40mm, the diameter of the gas flow channel is 30mm, the spacing is 50mm, the diameter of the molten iron and the molten slag flow channel is 20mm, and the spacing is 40mm; the arch height H2 is 300mm.

[0022] Application effect: The tapping temperature can be stabilized at about 1450℃, and it can be used continuously for 12 hours.

Embodiment 2

[0024] An embodiment of an integral honeycomb refractory hearth for gas cupola, replacing the water-cooled grate and refractory balls of a 3t / h gas cast iron furnace: hearth height H1 is 700mm; hearth shell boiler steel plate thickness 7mm; refractory The composition of the base material, non-sintering binder and composite additive is the same as that of Example 1. The radius of the annular convex and concave groove on the top of the refractory bed is R50mm, the gas flow channel diameter is 35mm, the spacing is 55mm, the molten iron and slag flow channel The diameter is 25mm, the spacing is 45mm; the height H2 of the dome is 320mm.

[0025] Application effect: The tapping temperature can be stabilized at about 1500℃, and can be used continuously for 10 hours.

Embodiment 3

[0027] An embodiment of an integral honeycomb refractory hearth for gas cupola, which replaces the water-cooled grate and refractory balls of a 5t / h gas cast iron furnace: hearth height H1 is 800mm; hearth shell boiler steel plate thickness 8mm; refractory material consists of The composition of the base material, non-sintering binder and composite additive is the same as that of Example 1. The radius of the ring-shaped boss and groove on the top of the refractory bed is R60mm, the diameter of the gas flow channel is 40mm, the spacing is 60mm, the molten iron and slag flow channel The diameter is 30mm, the spacing is 50mm; the dome shape H2 is 350mm.

[0028] Application effect: The tapping temperature can be stabilized at around 1550℃, and it can be used continuously for 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com