Multi-workstation nut clamping and conveying device

A clamping and conveying, multi-station technology, applied in conveyors, vibrating conveyors, transportation and packaging, etc., can solve the problems that the production efficiency of the production line is greatly affected, the accurate positioning of the nut cannot be guaranteed, and the picking and placing are not reliable. The effect of saving manpower, improving reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention are described in detail below.

[0034] The multi-station nut clamping and conveying device of the present invention is a power mechanism for automatically clamping and conveying nuts. It is an innovative process obtained after many tests on the process of weighing various nuts conveying and picking and placing. The automatic device of the preferred embodiment of the invention effectively solves the problem of conveying and clamping bulk nuts. The nuts are not jammed during the process of taking and clamping the nuts. The use of the sensor is used to position accurately, effectively clamping, and can be quickly transported. Go to the required processing station.

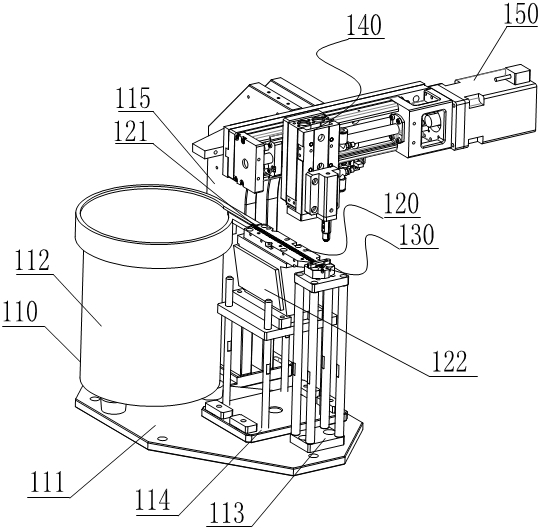

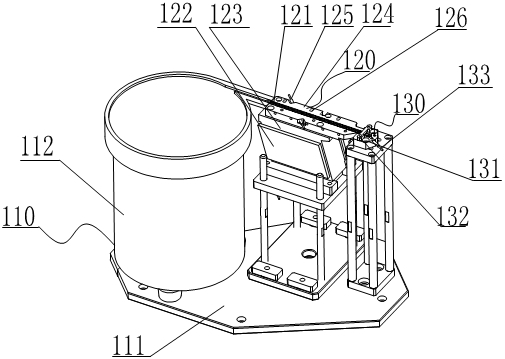

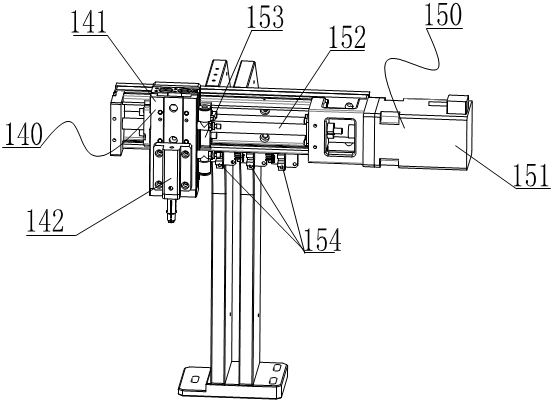

[0035] Such as figure 1 As shown, the multi-station nut clamping and conveying device of the present invention mainly includes five parts, which are respectively a vibrating plate module 110, a linear vibration conveying module 120, a nut positioning module 130, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com