Vibrating hopper for conveying syringe rubber plug

A technology of vibrating hoppers and syringes, which is applied in the field of medical machinery, can solve the problem that the tail of the rubber plug can not be solved, and achieve the effect of simple structure, stable transportation, accurate and stable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

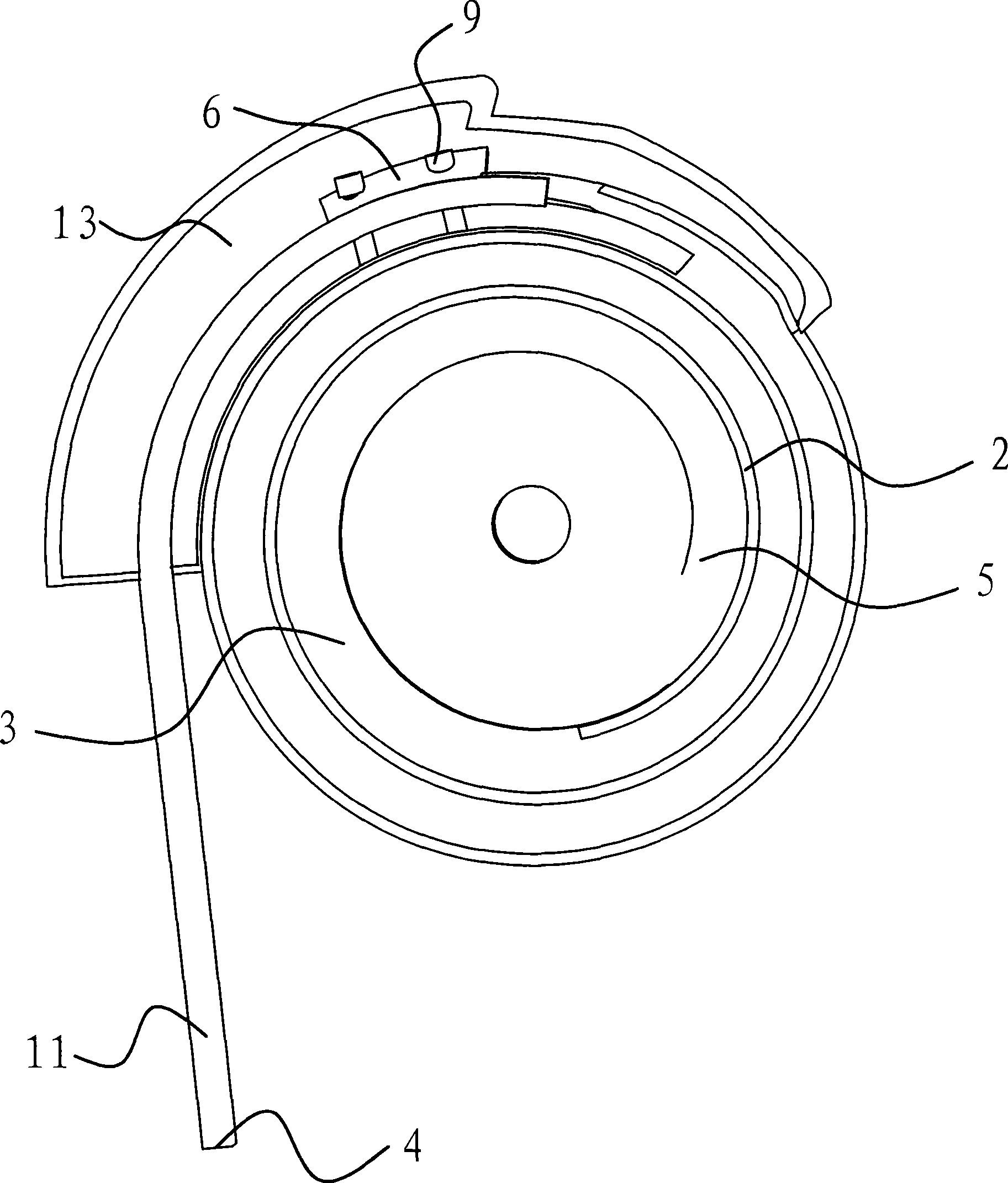

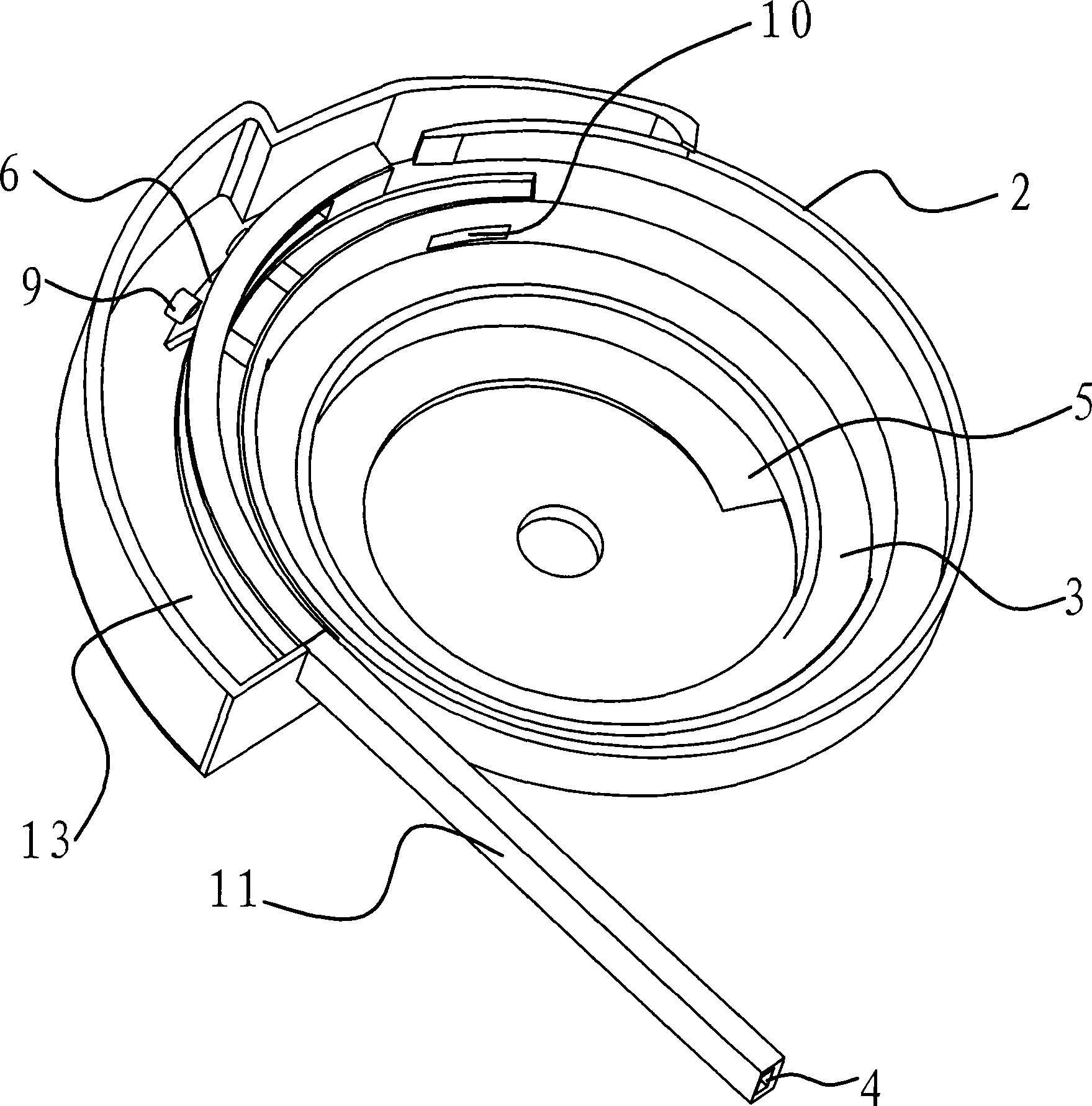

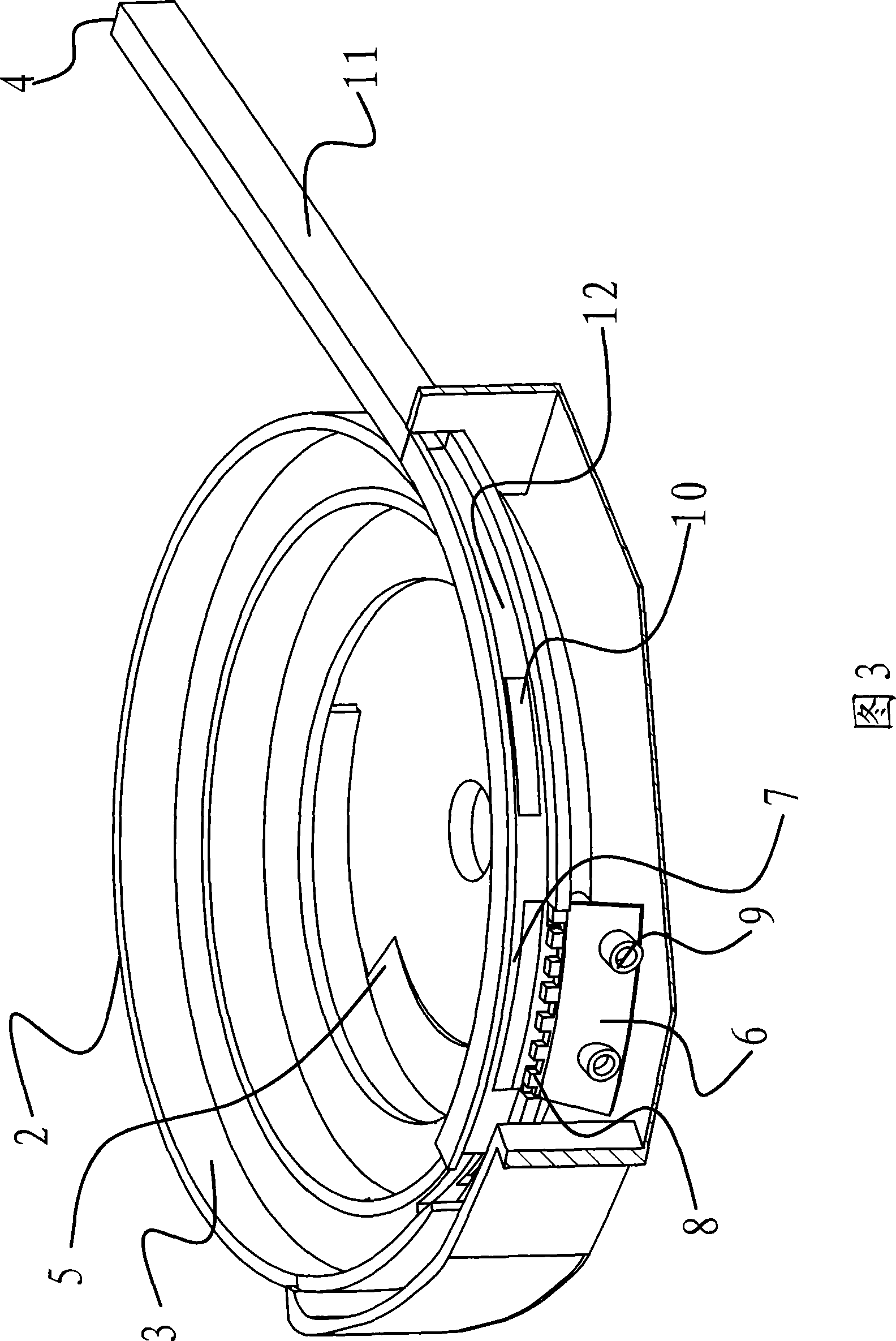

[0027] Such as figure 1 , figure 2 , Figure 3 and Figure 4 As shown, the vibrating hopper for conveying syringe rubber stoppers is used to output the rubber stopper 1 of the syringe to the assembly station for assembly in the state that the end of the rubber stopper 1 with the installation hole is facing upwards, including the hopper 2, the feeding channel 3, and the arrangement agencies and screening agencies. The rubber stopper 1 in this example is a rubber stopper 1 in an insulin syringe, which is cylindrical and has a mounting hole at one end.

[0028] Specifically, a spirally rising feeding channel 3 is provided on the hopper 2 , the highest point of the feeding channel 3 is the discharge port 4 , and the lowest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com