Tray charging method and vibratory tray charger

A charging machine and vibrating technology, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve problems such as high cost, large total stroke volume, suction nozzle stability and efficiency improvement, and achieve improved stability Sex, the effect of small total stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The vibrating tray loader of the present invention will be further described below in conjunction with the accompanying drawings.

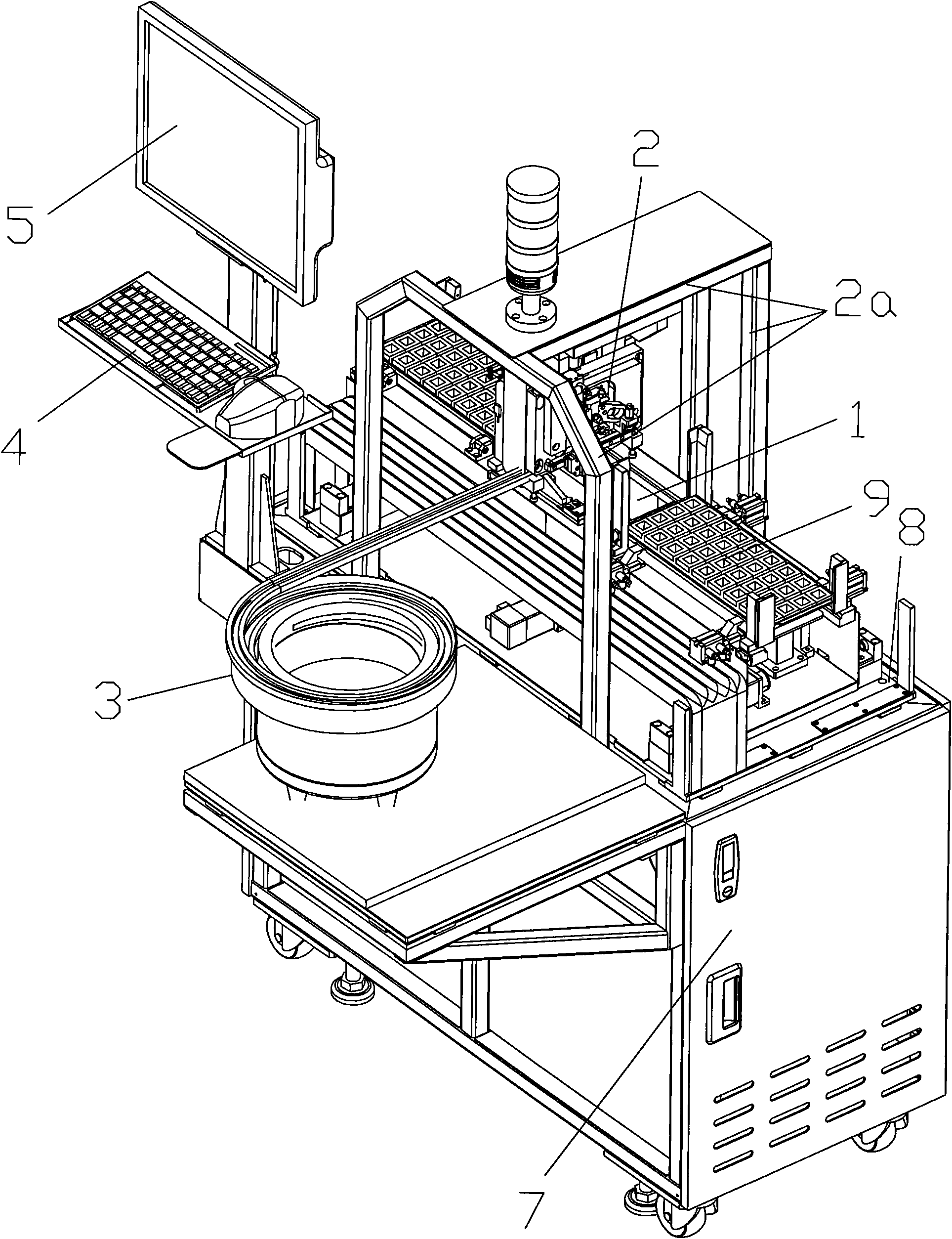

[0043] Such as figure 1 As shown, the vibrating tray loader of the present invention includes a hopper type vibrating device 3, a pick-and-place device 2, a pallet adaptive loading device 1 and an electrical control system 7, wherein the hopper type vibrating device 3 and the pallet automatically The adaptable charging devices 1 are installed on the workbench panel 8, and the grasping and discharging device 2 is installed on the workbench panel 8 through the mounting bracket 2a.

[0044] Such as Figure 7 and 8 As shown, the pallet self-adaptive loading device 1 includes a longitudinal conveying device that drives the pallet to move in the longitudinal direction and a transverse conveying device 15 that drives the longitudinal conveying device to move in a transverse direction perpendicular to the longitudinal direction, and the longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com