Method for assembling faucet valve core and fully automatic assembly machine

An assembly method and faucet technology, applied to assembly machines, vibrating conveyors, conveyors, etc., can solve the problems of no mechanized assembly valve core, increase the difficulty of mechanical assembly, and low assembly efficiency, so as to achieve small footprint and high production efficiency , the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

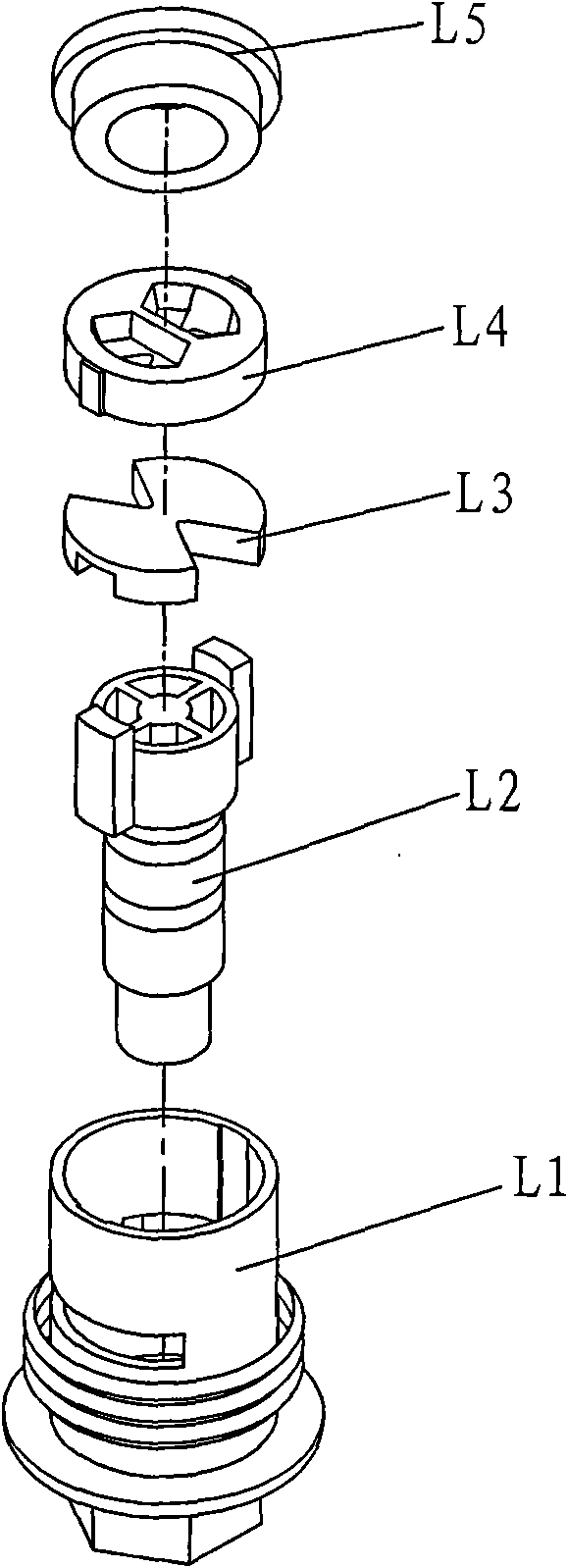

[0083] A method for assembling a faucet spool, the assembling steps are as follows:

[0084] Step 1: Position the spool, and sort out the spool shells with the hexagonal end facing down and the round end facing up from several spool shells, and fix them on the first station of the working platform;

[0085] Step 2: install the screw rod, turn the spool shell of the first station to the second station, the protruding end of the finished screw rod faces upwards, and the downward end of the screw rod is connected from the round end of the spool shell (spool shell) The upper end opening after being positioned) is assembled into its central through hole;

[0086] Step 3: Install the small ceramic piece, the valve core shell of the second station is turned to the third station, the grooves on both sides of the tidied small ceramic piece face down, and the upward smooth surface of the small ceramic piece is wiped with silicone oil and assembled in the In the through hole of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com