Full-automatic inductance winding machine and winding method thereof

A winding machine, fully automatic technology, used in vibration conveyors, inductance/transformer/magnet manufacturing, circuits, etc. High lap accuracy, easy operation and maintenance, convenient and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

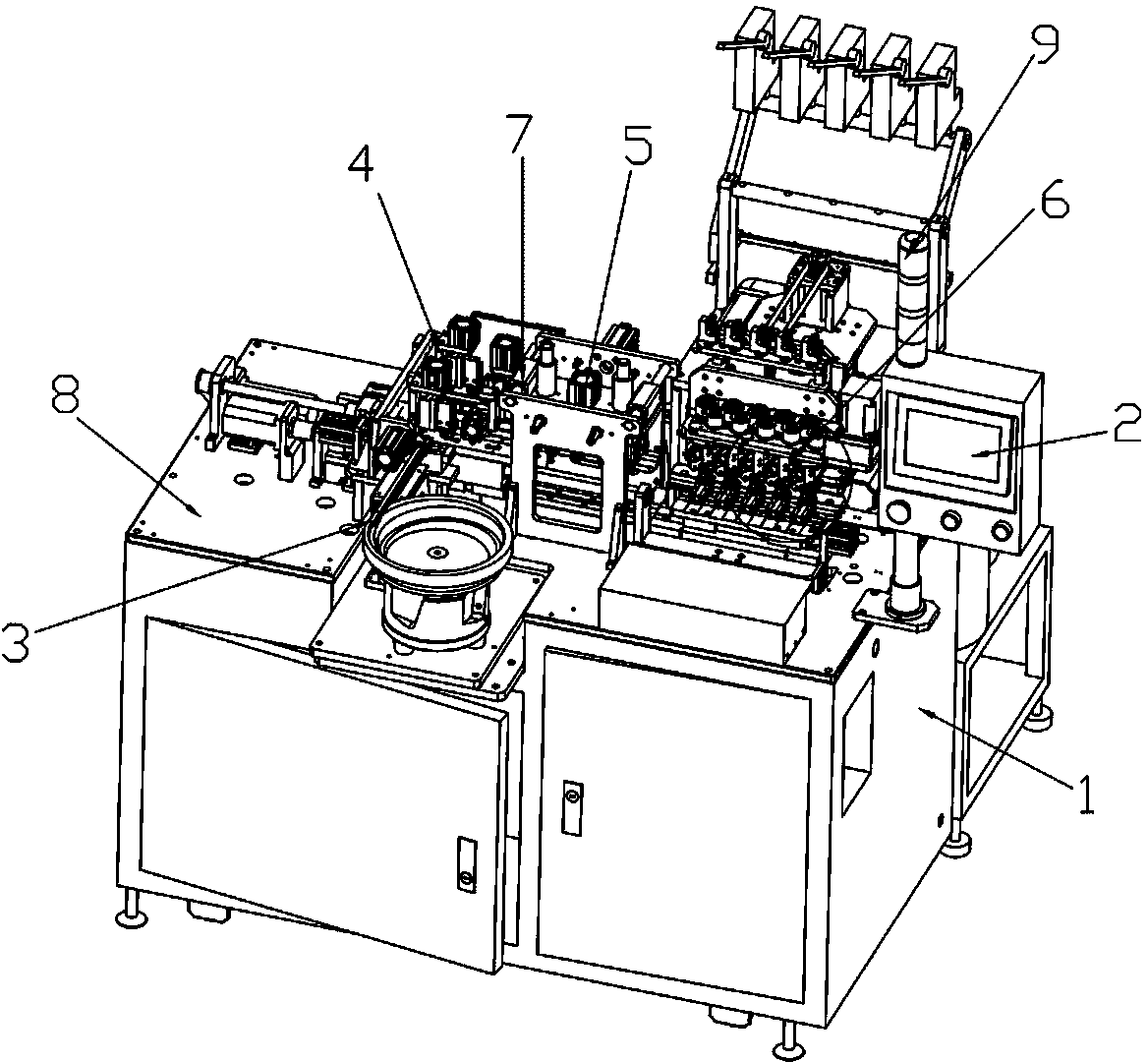

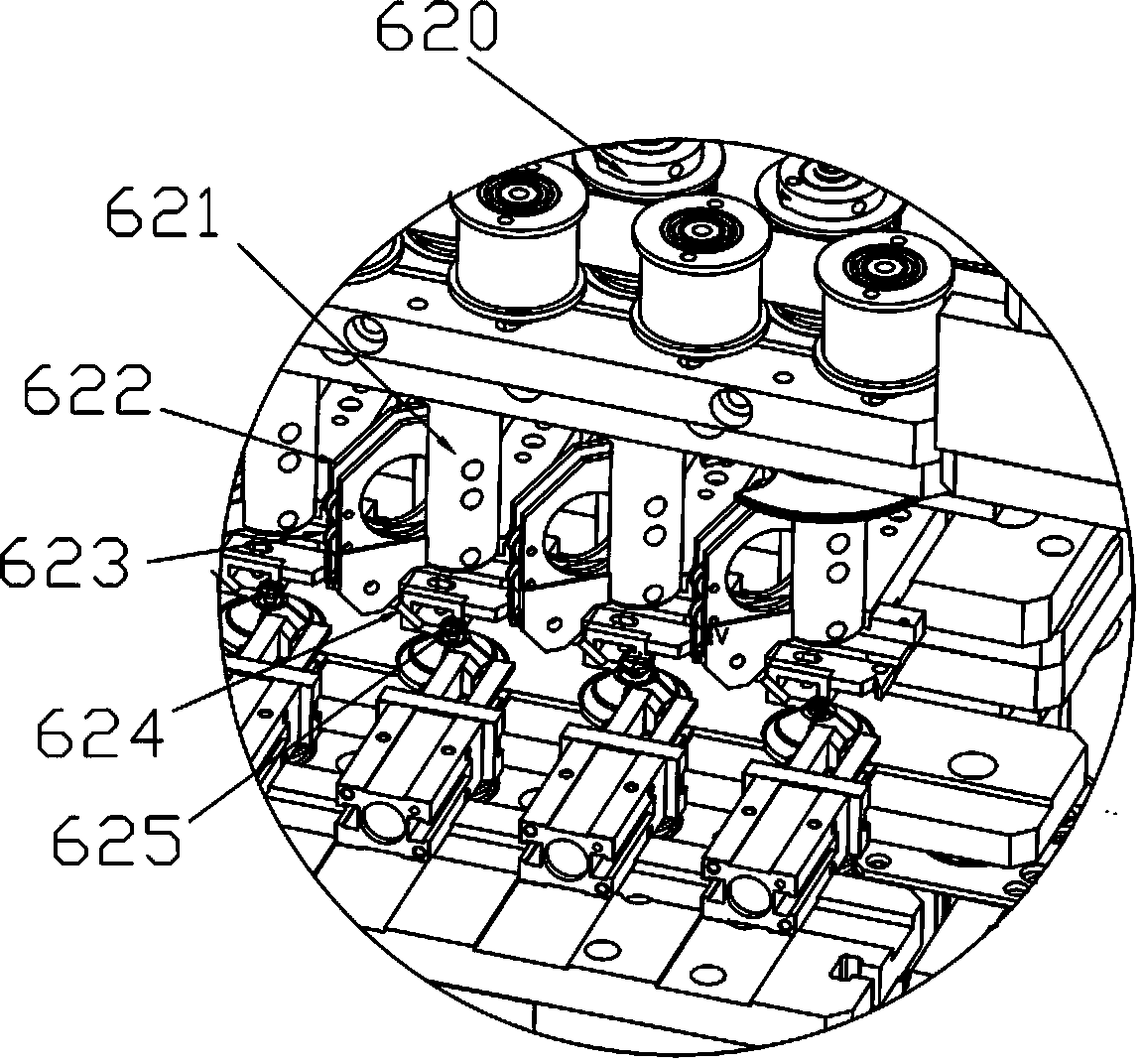

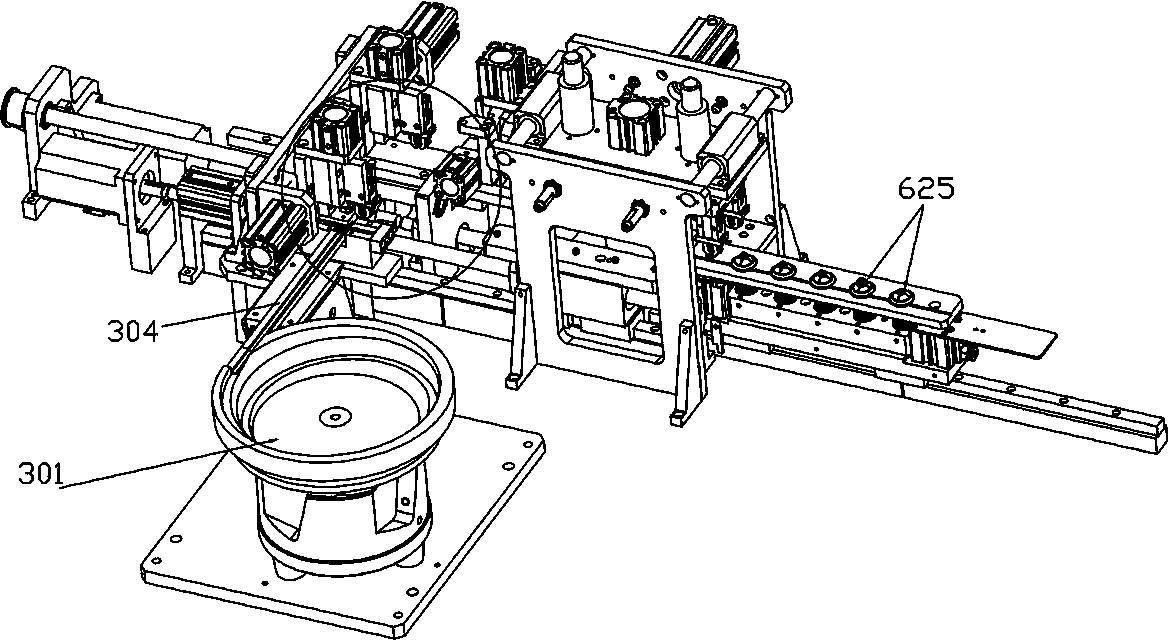

[0056] In this embodiment, refer to Figure 1 to Figure 10 , its specific implementation structure includes a bracket 1, an operation panel 2, a mechanical feeding mechanism 3, a mechanical unloading mechanism 4, a transfer mechanism 5, a winding mechanism 6 and a secondary crimping mechanism 7. Bracket 1 is used as the carrying device of the whole machine, and an electric control system for controlling the whole machine is arranged inside the frame, and an operating platform 8 is provided on the surface of the bracket 1, such as figure 1 As shown, the mechanical loading mechanism 3 , the mechanical unloading mechanism 4 , the transfer mechanism 5 , the winding mechanism 6 and the operation panel 2 are all installed on the surface of the operation platform 8 . The winding mechanism 6 is located at the tail end of the workpiece 625 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com