Novel magnet ring winding machine

A new type of wrapping wire technology, applied in the field of small magnetic ring processing equipment, can solve the problems of high labor cost, low operation efficiency, limited machine processing range, etc., and achieve the effect of low labor cost, high processing efficiency and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

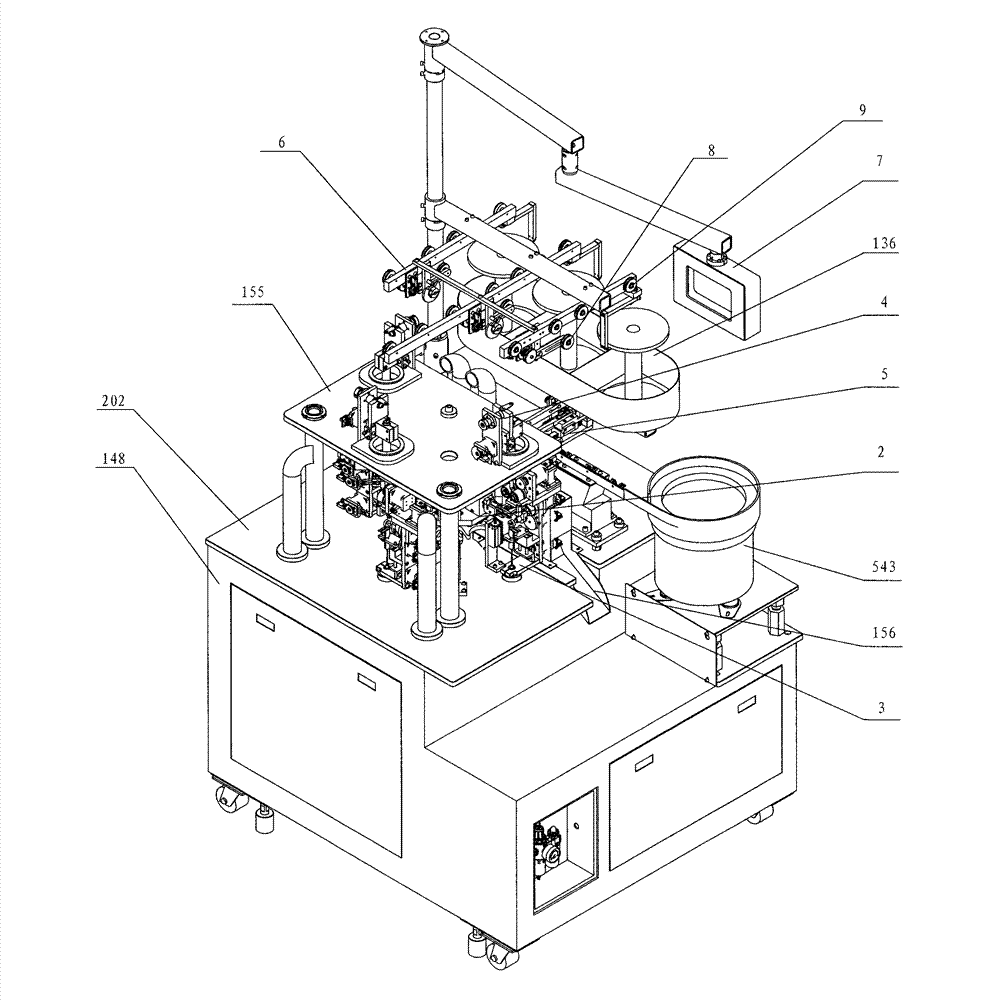

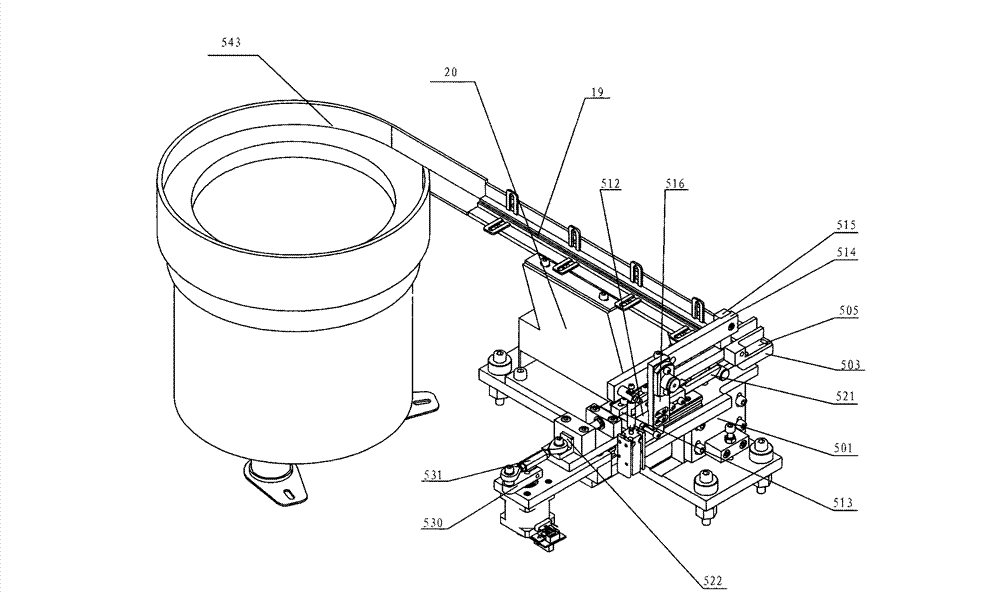

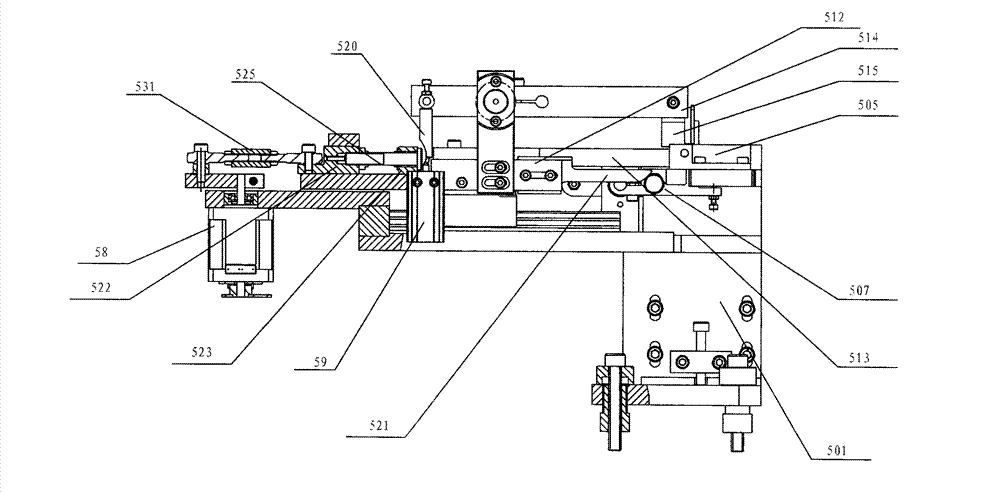

[0031] Embodiment: refer to attached figure 1 , a new type of magnetic winding machine, including the bottom plate 202 located on the frame 148, the threading installation plate 155, the vibrating hopper 543, the dropping hopper 156, the operation box 7, the material rack 136, the wire rack 6, the turntable mechanism 2, Feeding mechanism 5, wire feeding and trimming mechanism 4 and threading rotary lifting mechanism 3, the working turntable in the turntable mechanism 2 is an octagonal turntable 224, on which a workpiece clamping and turning mechanism 288 is provided every 45°, corresponding to the feeding workers Position 11, the first waiting station 12, the second winding station 13, the third waiting station 14, the fourth winding station 15, the fifth turning waiting station 16, the sixth winding station 17, the Seven turning and waiting station 18; the feeding mechanism 5 is arranged between the vibrating hopper 543 and the feeding station 11; the wire feeding and trimmin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com