Control device for servo power turret

A technology of control device and power turret, applied in the direction of digital control, electrical program control, etc., can solve the problems of easy overload and burning of the drive motor, fluctuation of turret indexing speed, easy damage of decoding system, etc., to improve flexibility and versatility, increase mechanical life, reduce the effect of tool change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

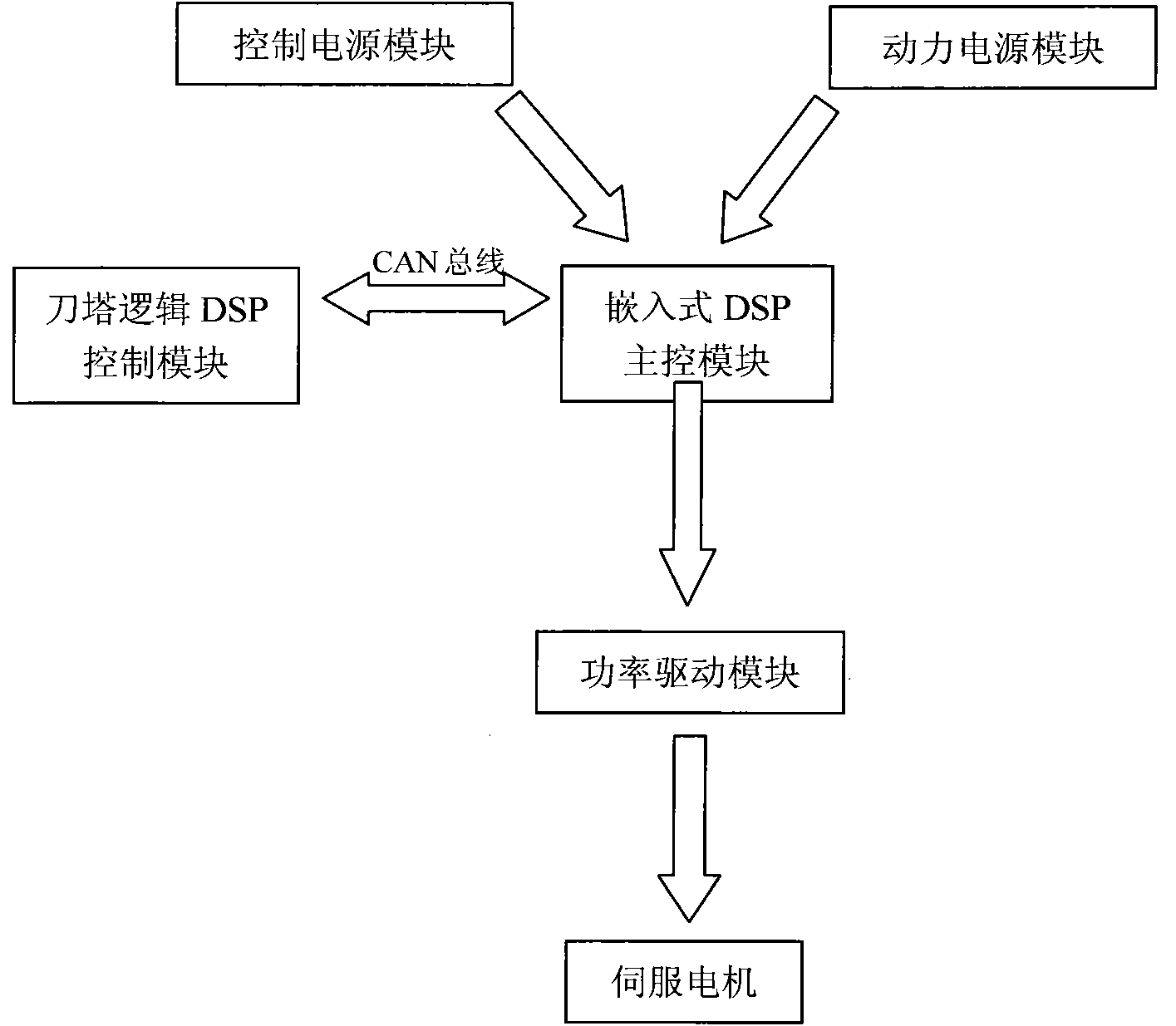

[0017] Such as figure 1 As shown, the control system of the servo power turret control device of the present invention includes: a control power supply module, a power supply module, an embedded DSP main control module, a turret logic DSP control module, and a drive module. The control power supply module and the power supply module respectively provide control power supply and power supply to the embedded DSP main control module. The turret logic DSP control module is responsible for receiving the user's input signal and decoding the signal into an index signal, and then sending the index signal to the embedded DSP main control module through the CAN bus, and outputting the turret status signal and fault in real time Test results. The embedded DSP main control module drives the servo motor to the target position after receiving the index signal sent by the turret logic DSP control module. At the same time, the embedded DSP main control module also sends the turret position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com