Shaft type workpiece floating clamping and driving device for four-axis machining center

A technology for four-axis machining centers and shaft workpieces, which is applied to metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problems of high precision, long clamping time, and large positioning errors, and achieve The effect of improving the processing efficiency of the equipment, high precision of rotation indexing, and fast driving indexing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described further;

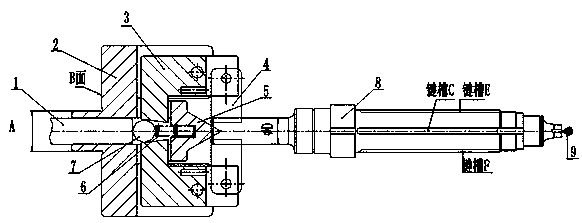

[0014] Such as figure 1 As shown, the four-axis machining center shaft workpiece floating clamping drive device of the present invention includes a support body 2 and a rotating arm 3, the rotating arm 3 is rotatable, and is movable between the support body 2; on the support body 2 , a hole is arranged horizontally, the ejector rod 1 passes through the hole transversely, and a pushing device is arranged at the rear end of the ejector rod 1, which can be a commonly used hydraulic cylinder, air cylinder, etc., and an active force is applied to push the ejector rod 1 to move laterally; Corresponding to the position of the ejector rod 1, the arm 3 is provided with a transverse tapered hole with a large outer diameter and a smaller inner diameter, and a steel ball 7 is arranged in the tapered hole; the steel ball 7 is provided with a compression spring for re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com