Floor mopping module and cleaning robot

A technology for cleaning rollers and sponge rollers, which can be used in cleaning machinery, cleaning equipment, machine parts, etc., and can solve the problems of sewage residue, short service life, and ground sewage residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

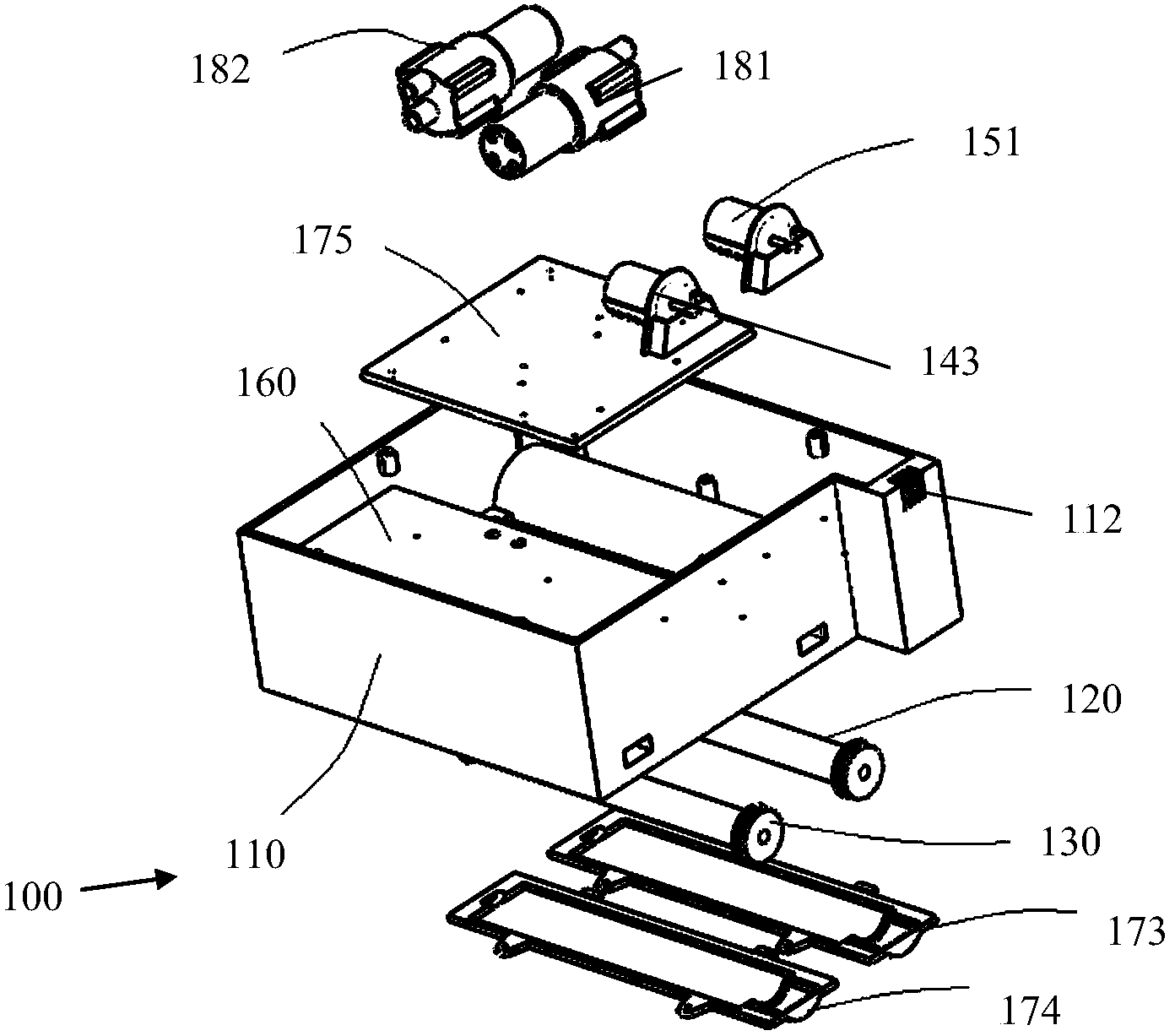

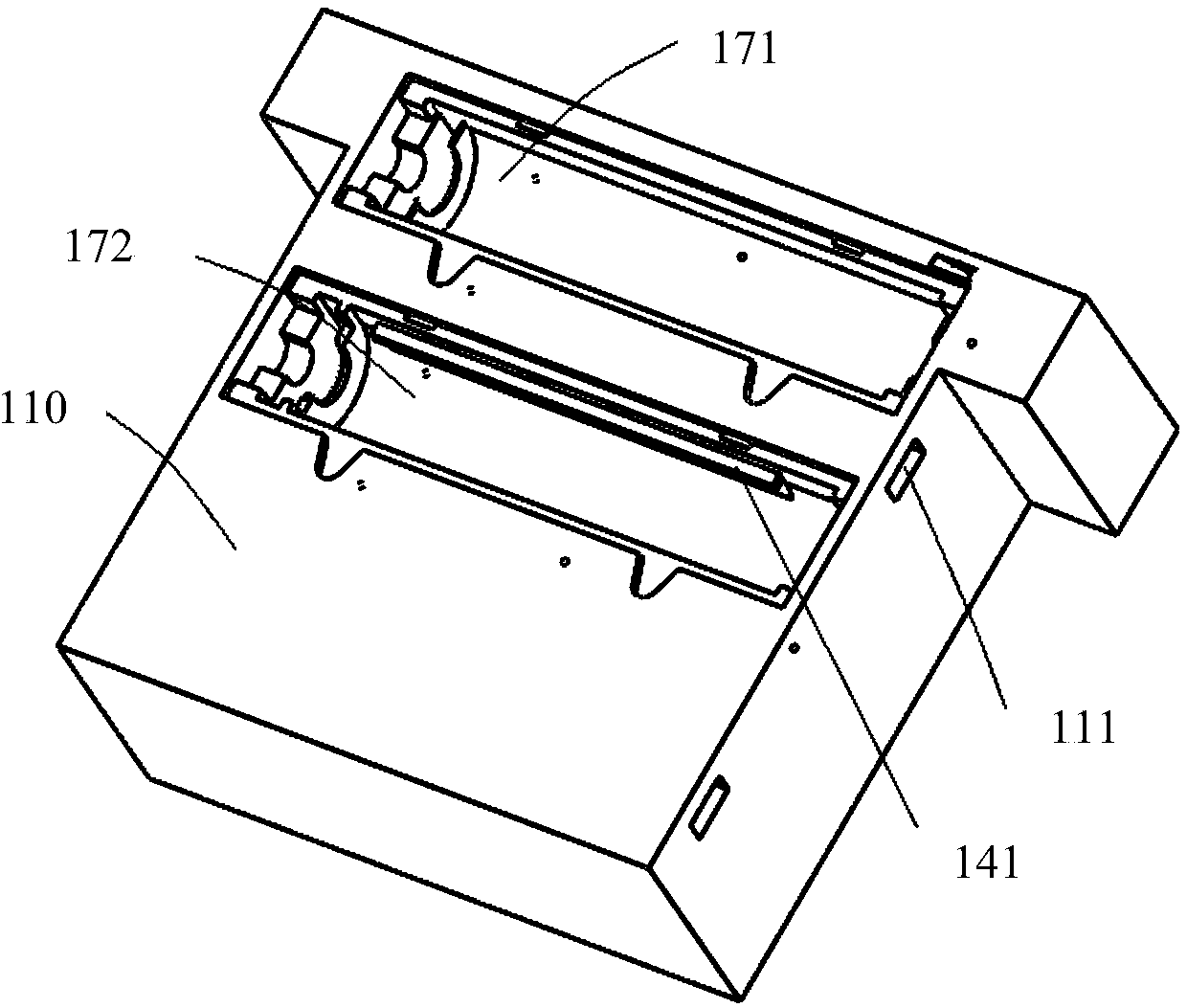

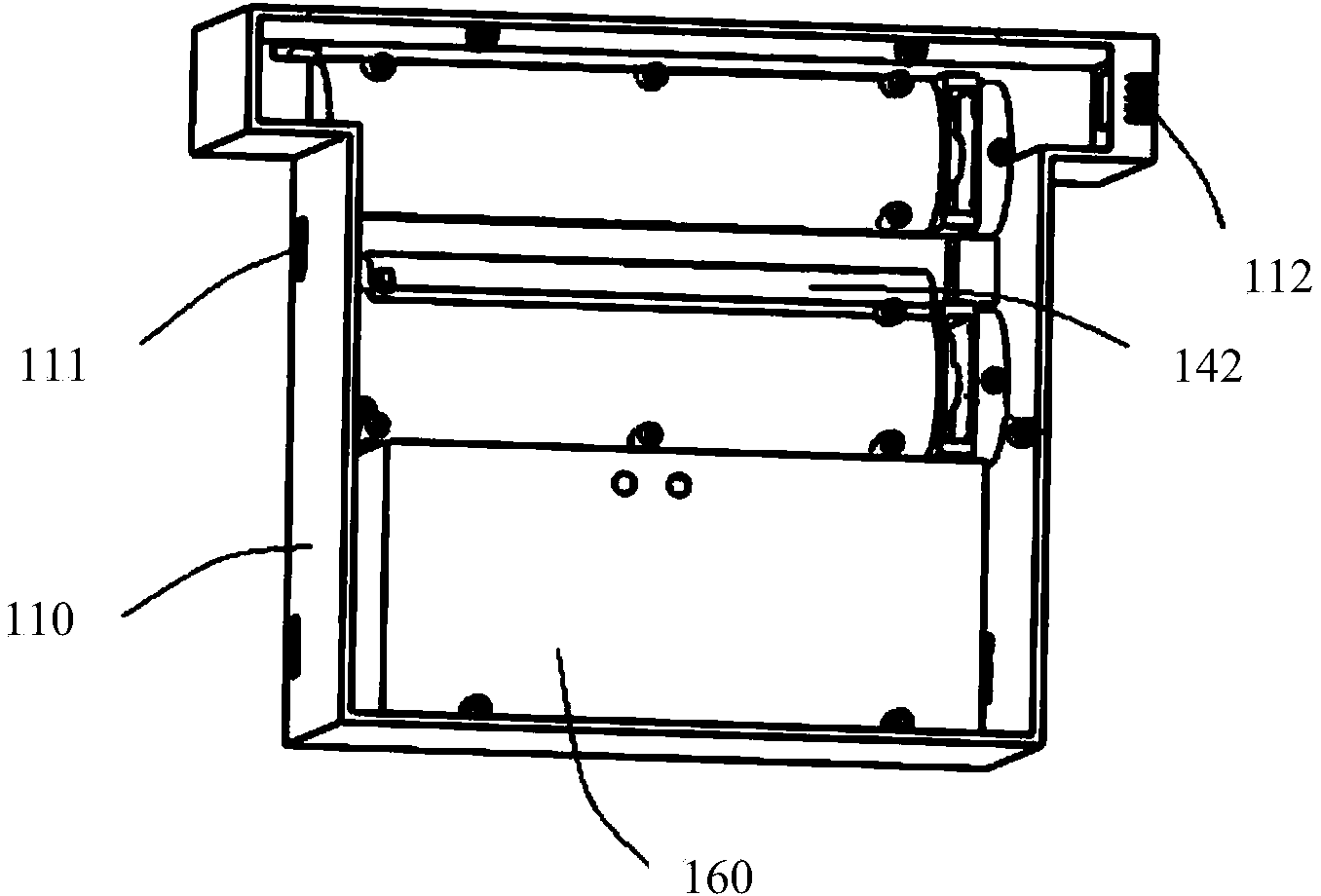

[0030] The embodiment of the invention discloses a floor mopping module, including an installation platform, nozzles installed on the installation platform, a cleaning roller, a water supply system and a power system, the water supply system is connected to the nozzles, used for water supply of the nozzles, and the power system and cleaning Roller connection for rotational drive of the cleaning roller, wherein,

[0031] The mopping module also includes a sponge roller and a sewage recovery system installed on the installation platform. The sponge roller is connected to the power system for rotating the sponge roller. The sewage recovery system is connected to the sponge roller for sewage recovery of the sponge roller;

[0032] The nozzle is located at the front end of the installation platform, the cleaning roller and the sponge roller are respectively located at the bottom of the installation platform, and the cleaning roller is located in front of the sponge roller.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com