Axial rheological gap bionic corn threshing device

A corn threshing and clearance technology, applied in threshing equipment, agriculture, application, etc., can solve the problems of corn grain entrainment loss, corn grain stress, grain damage, etc., to facilitate subsequent use, reduce organic matter loss, and improve threshing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

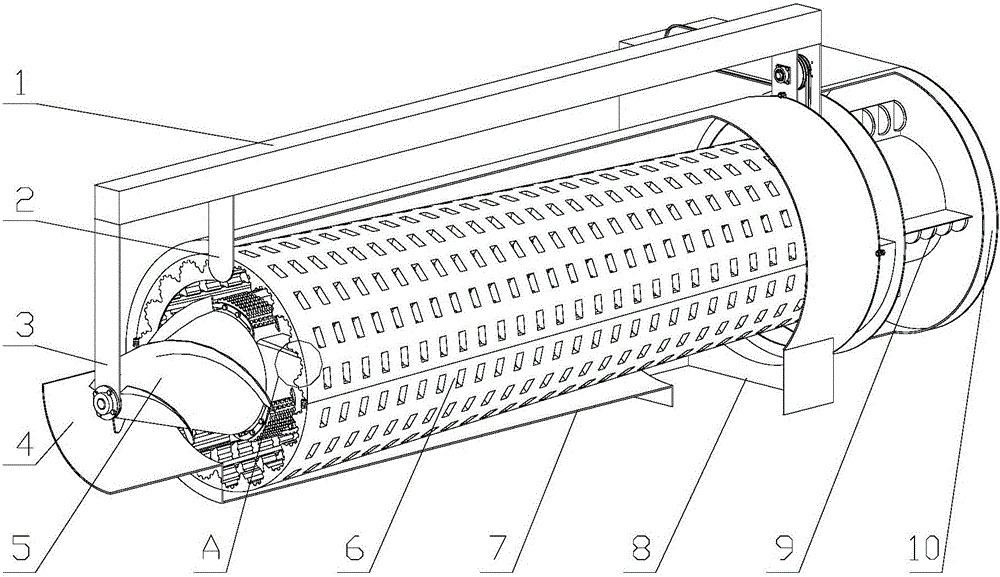

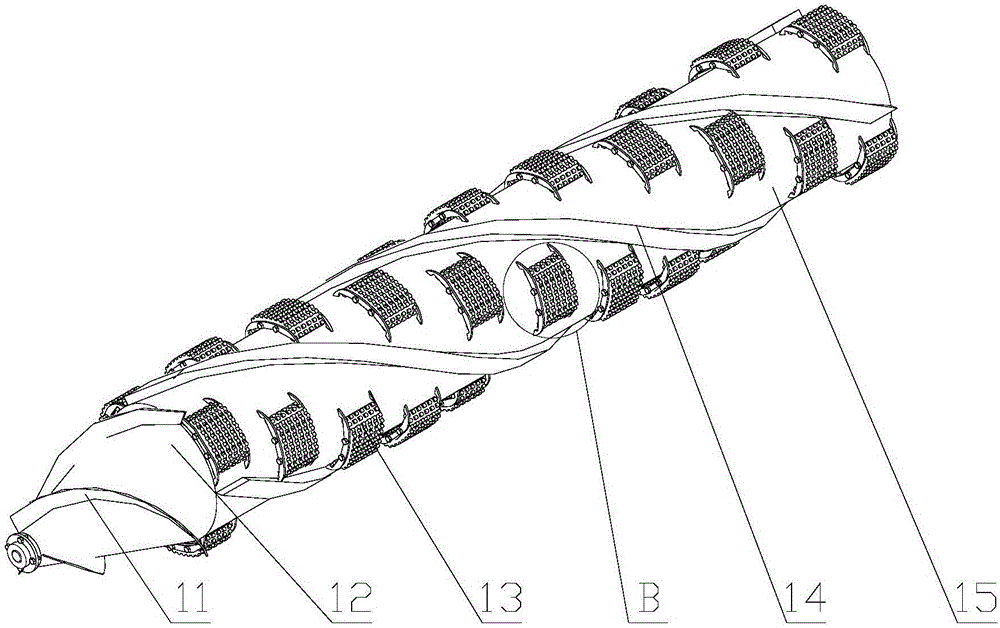

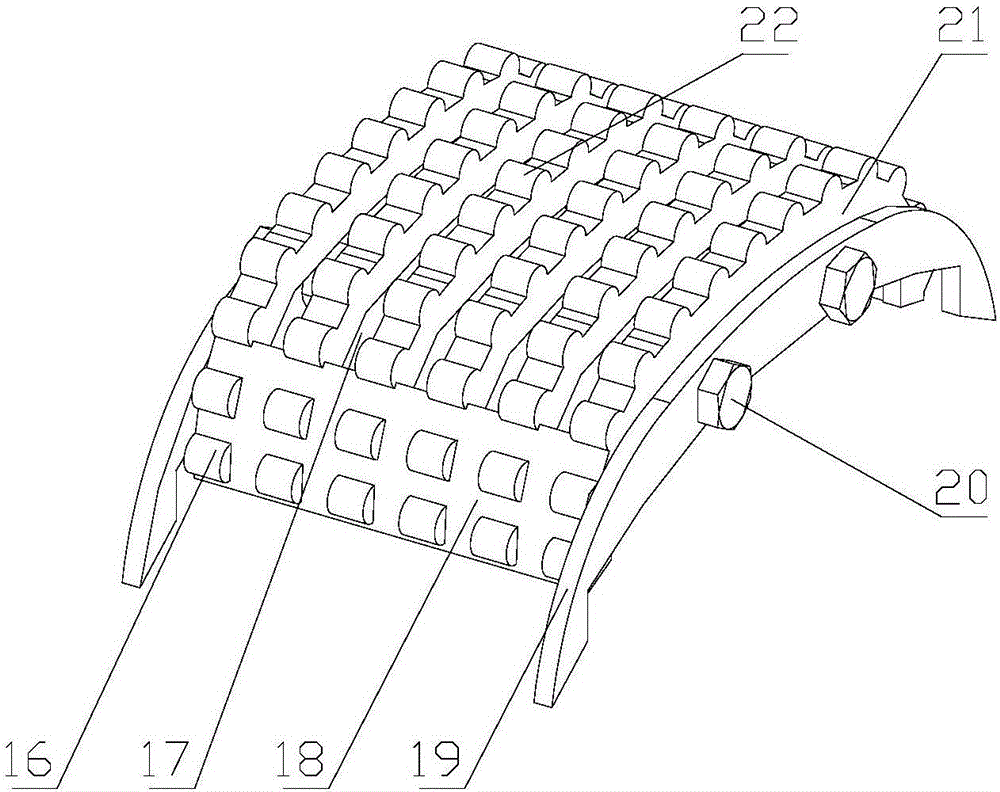

[0021] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the present invention comprises frame 1, threshing cylinder 5, concave plate sieve 6, machine cover 7 and corn cob recovery mechanism 10, and machine cover 7 is fixed on the bottom of frame 1, and concave plate sieve 6 is fixed on machine cover 7 Inside, the threshing drum 5 is fixed on the inside of the concave plate sieve 6, and the corn cob recovery mechanism 10 is fixed on the rear portion of the machine cover 7; the frame 1 includes a boom 2, a column 3, a first pulley 26, a first belt 27. The second belt 31, the third belt 32 and the fourth pulley 33, the column 3 is fixed on the front of the frame 1, the boom 2 is fixed on the rear of the column 3, and the fourth pulley 33 is fixed on the frame 1 The rear portion of the first pulley 26 is fixed on the rear of the fourth pulley 33, the first belt 27 is fixed on the outside of the first pulley 26 and the second pulley 29, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com