Combine harvester

A technology for combine harvesters and grains, used in harvesters, cutters, motor vehicles, etc., to solve problems such as inability to accurately measure moisture content and inability to rotate electrode rollers well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066]

[0067] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0068]

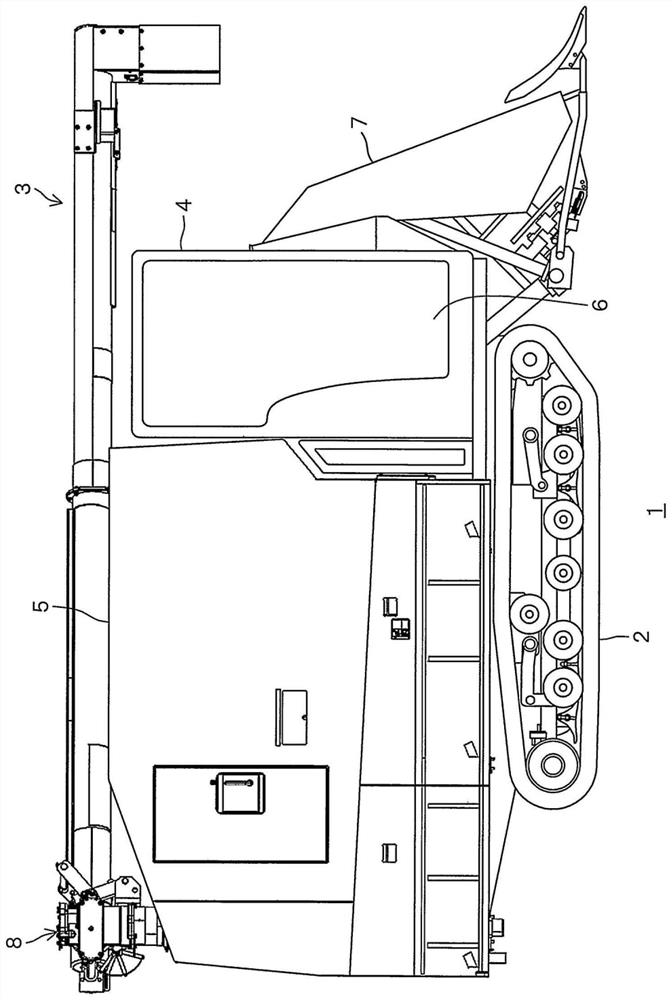

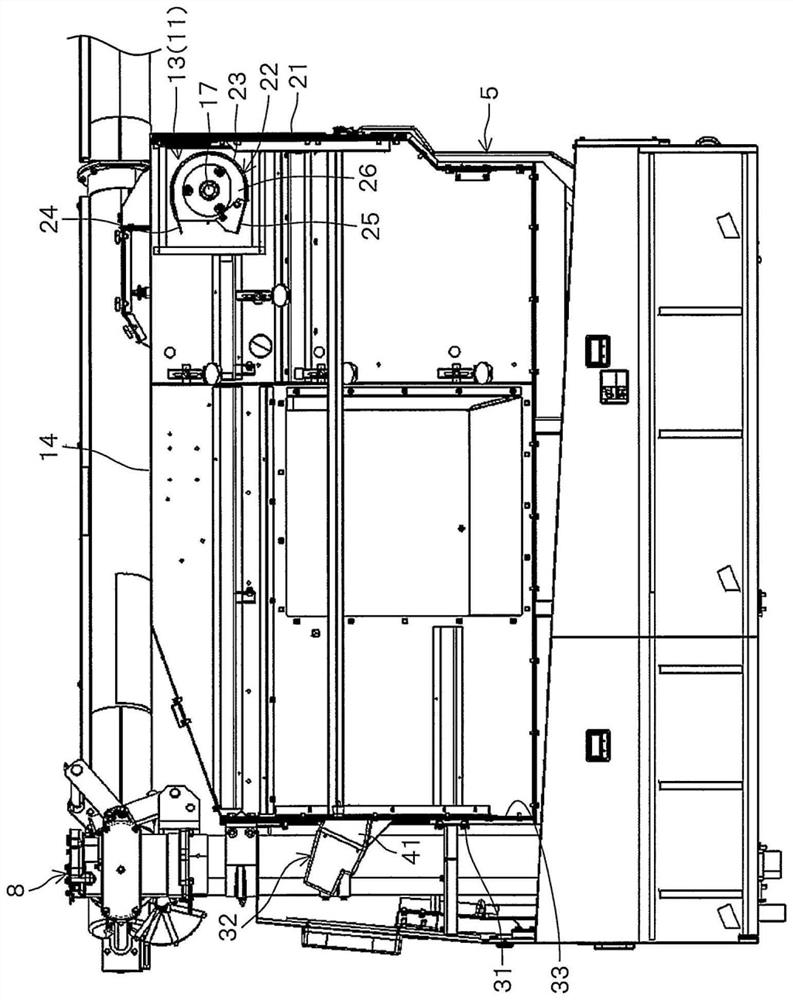

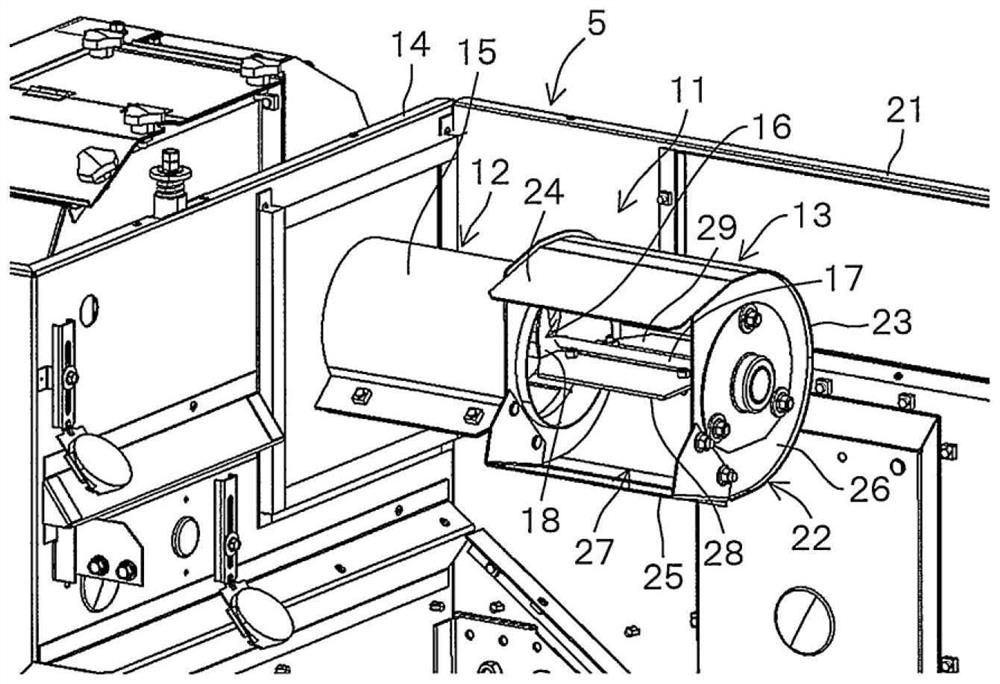

[0069] figure 1 It is a right side view of the combine harvester 1 which concerns on one Embodiment of this invention.

[0070] The combine harvester 1 is an example of the harvester which performs reaping of a grain stalk and threshing from a grain stalk while traveling on a field. The combine harvester 1 employs a pair of left and right crawler belts 2 as a traveling device capable of crossing uneven ground such as a field, and a cab 4 and a grain box 5 are provided on a body 3 supported by the pair of left and right crawler belts 2 .

[0071] Cab 4 is disposed on the front end portion of crawler belt 2 . The driver's cab 4 provides a space for a driver to sit inside, and operating components such as a driver's seat on which the driver sits, an operating lever, and an operating pedal are arranged in the space. An openable and closabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com