Novel flat threshing combine harvester

A combine harvester, flat plate technology, applied in the direction of harvester, threshing equipment, cutter, etc., can solve the problems of low harvesting efficiency, prone to failure, complex structure, etc., and achieve the effect of high work efficiency, effective threshing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

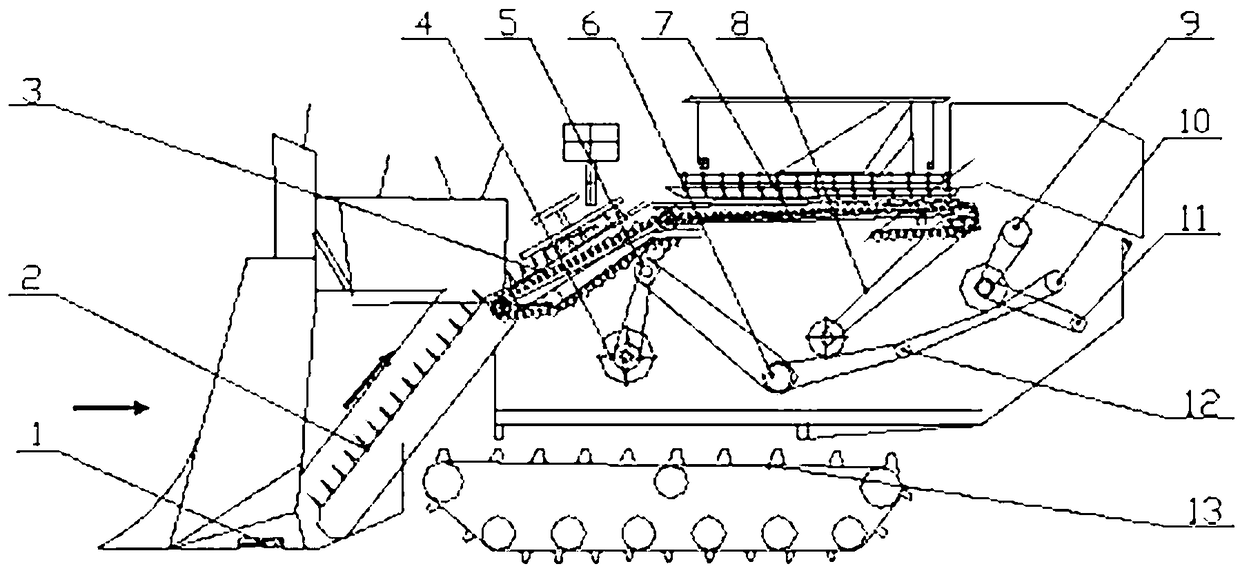

[0016] figure 1 The medium and new type flat threshing combine harvester is mainly composed of header device, inclined conveying chain and finger pulling, feeding chain, diesel engine, rear drive spindle, grain collecting device, threshing device, threshing chain drive, grass cutting and grass discharge device, cutting Groove fast shaft, cleaning device, secondary auger drive shaft, walking device, etc.; the header device is transported by an L-shaped header, mainly composed of a front grain divider, a grain-holding chain box, a grain-holding chain, a clip Holding star wheel, horizontal conveying chain, clamping chain, cutter, cutter gear box, front falling pallet, middle falling pallet, falling conveying trough, header lifting cylinder and other parts; the falling pellets The recovery tank can recover the grains dropped during the horizontal conveying process, and directly transport the falling grains to the threshing drum through the inclined recovery tank chain; the clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com