Crushing process of alumina crusting block and production line thereof

A technology of incrustation and alumina, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc. Material transportation and other issues, to reduce consumption and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

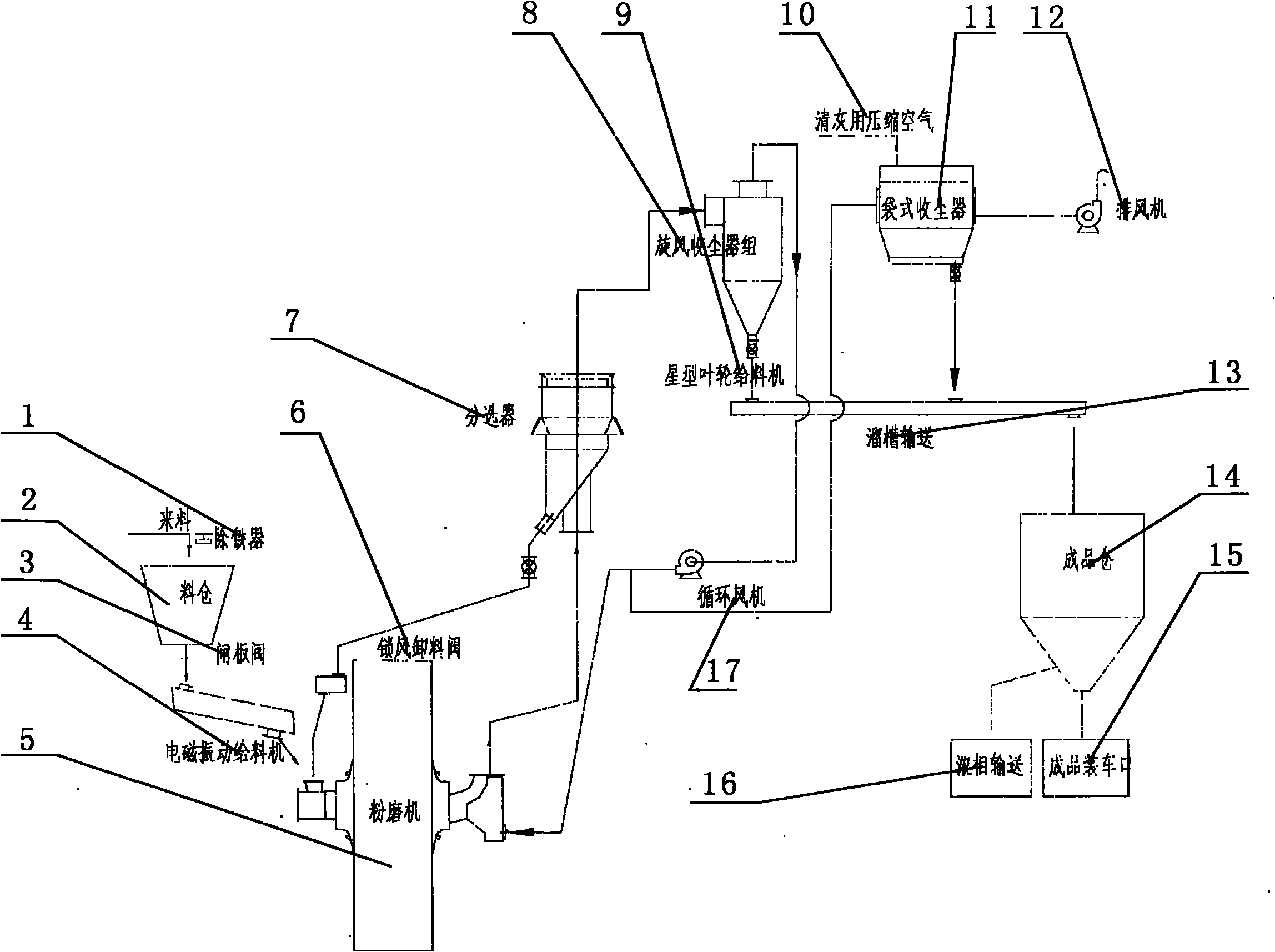

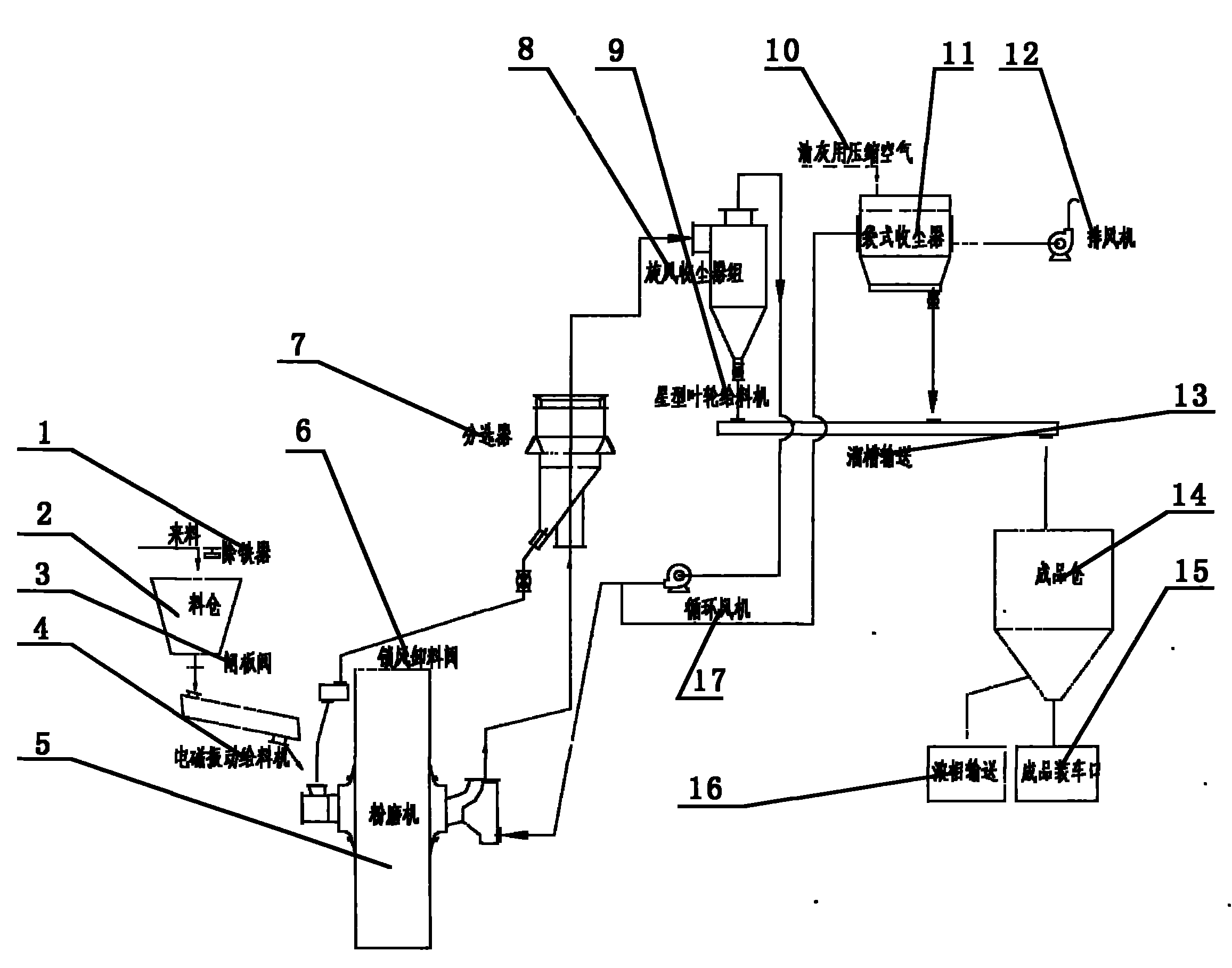

[0039] like figure 1 As shown, the mechanical part of the crushing system includes a raw material bin 2, an electromagnetic vibrating feeder 4, a pulverizer 5, a separator 7, a cyclone dust collector 8, a bag dust collector 11, and a chute 13, which are sequentially connected through pipelines. , finished product warehouse 14;

[0040] The upper part of the raw material bin 2 is provided with an iron remover 1 for removing iron filings mixed in the alumina crust, and the lower part of the raw material bin 2 is provided with a gate valve 3 to control the discharge amount of the alumina crust;

[0041] The lower end of the classifier 7 has two pipelines, one pipeline is connected to the outlet end of the pulverizer 5, and the other pipeline is connected to the inlet end of the pulverizer 5, and the air lock discharge valve 6 is provided between the pipelines. To disconnect the pipeline path between the separator 7 and the inlet end of the pulverizer 5 in the process; the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com