Bucket production line device and method for crushing aluminum oxide crusting blocks

An alumina and production line technology, applied in grain processing and other directions, can solve the problems of high equipment failure rate, low processing efficiency, reduced equipment operation rate, etc., to improve the working environment, improve production efficiency, and prevent segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

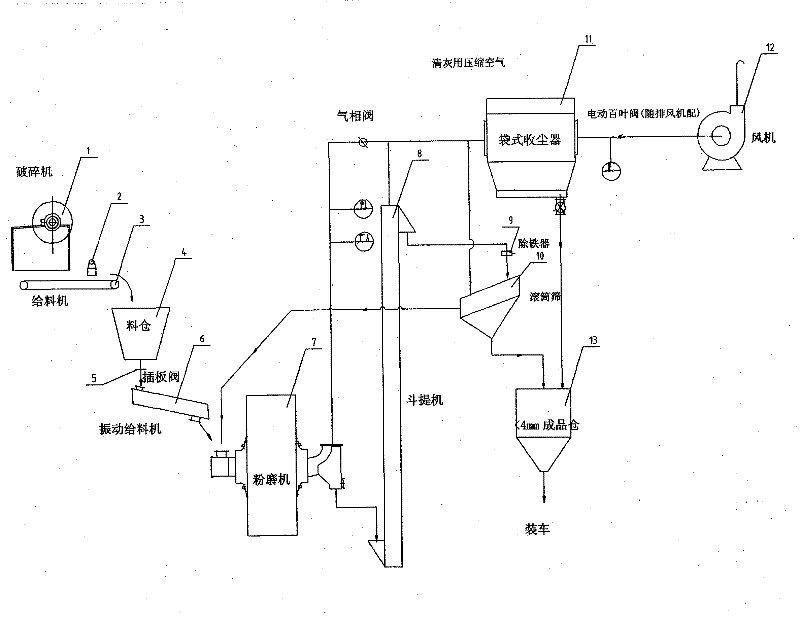

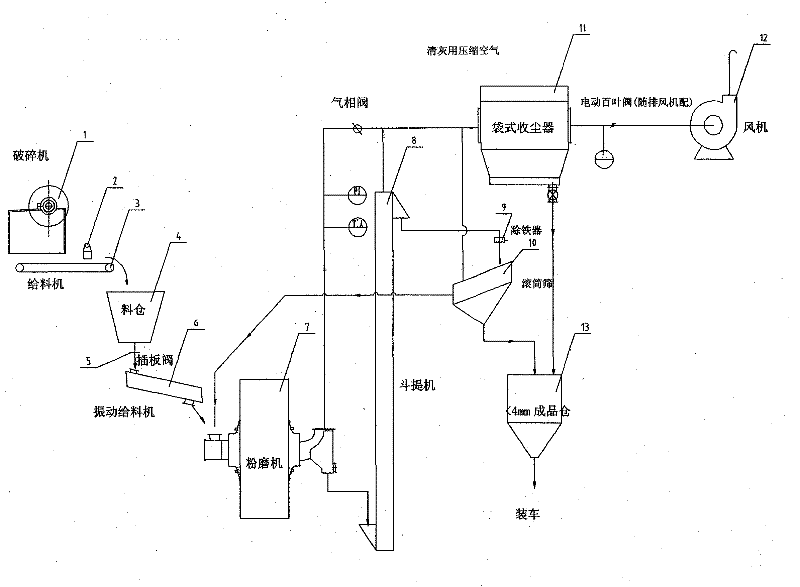

[0043] As shown in the figure, the mechanical part is composed of: crusher 1, first iron remover 2, conveyor 3, raw material bin 4, flapper valve 5, vibrating feeder 6, pulverizer 7, bucket elevator 8 , a second iron remover 9, a vibrating screen 10, a bag filter 11, an exhaust fan 12, and a finished product warehouse 13; the conveyor 3 is installed below the crusher 1, and the pipeline installation between the conveyor 3 and the crusher 1 is the first An iron remover 2, a raw material bin 4 is installed below one end of the conveyor 3, a vibrating feeder 6 is installed under the raw material bin 4, and a slide valve 5 is installed between the vibrating feeder 6 and the raw material bin 4 through a pipeline;

[0044] The bottom of one end of the vibrating feeder 6 is connected to the pulverizer 7. One side of the outlet of the pulverizer 7 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com