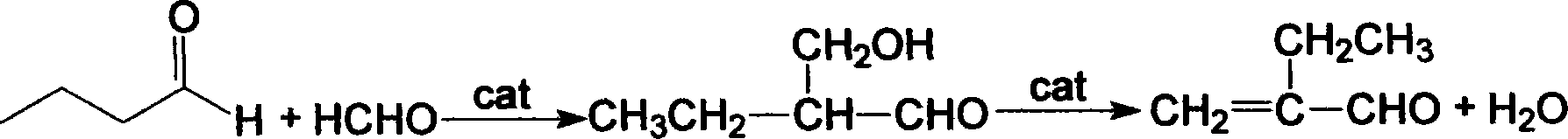

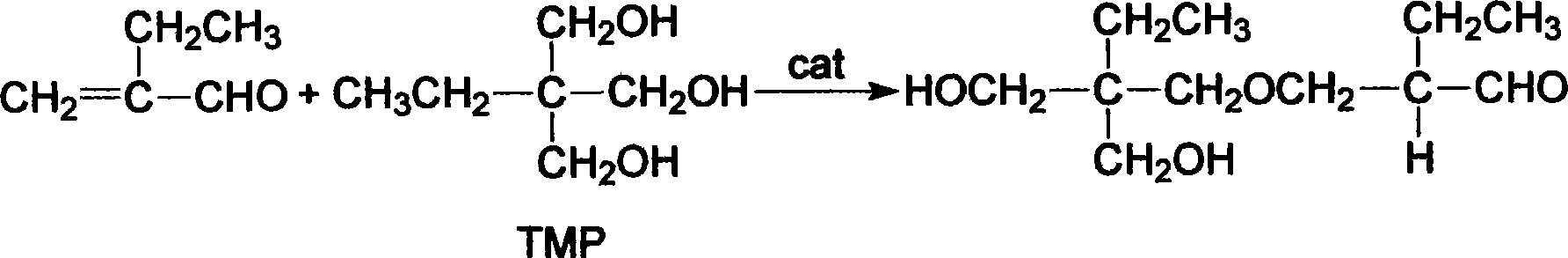

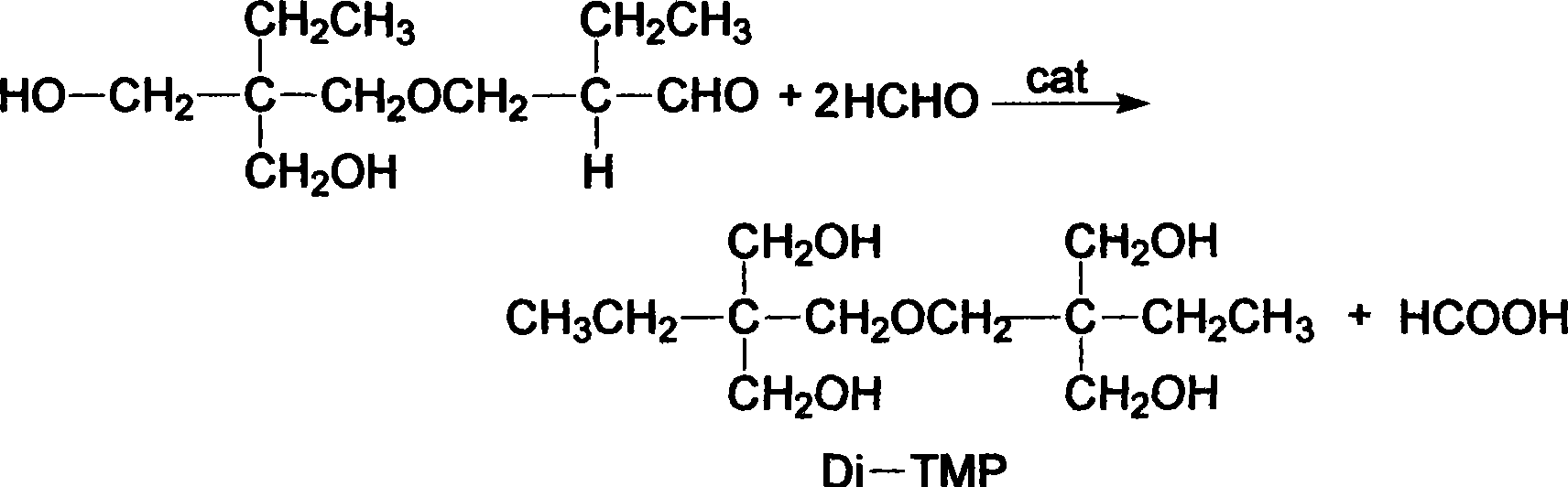

Process of synthesizing bis (trihydroxy methyl propane)

A technology of ditrimethylolpropane and trimethylolpropane, which is applied in the field of synthesizing ditrimethylolpropane, can solve the problems of low selectivity of reactants, many by-products, difficulties, etc., and achieve easy recovery and recycling, Ease of industrial production and the effect of meeting a large number of needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) In a four-necked flask equipped with stirring, a thermometer, a dropping funnel and a condenser, first add 144g of 50wt% n-butyraldehyde solution accurately measured, start stirring and be warming up to 50°C, and then stir within 1 hour to 121.2g of triethylamine and 110g of 30wt% formaldehyde solution were dropped simultaneously in the container for reaction, and the reaction was continued for 1.5 hours after the addition was completed, and then the reaction solution was cooled to room temperature; then,

[0027] (2) Add 737g of TMP to the reaction solution obtained in (1) under stirring, and stir to raise the temperature to 90°C, and react for 3h, then cool the reaction solution to room temperature; then,

[0028] (3) Heating the reactants to 80° C. under stirring, and then continuously adding 250 g of 30 wt % formaldehyde solution to the reaction solution obtained in (2) within 1 hour for reaction. After the addition, continue to stir and react for 2 hours to obta...

Embodiment 2

[0031] (1) In the four-neck flask equipped with stirring, thermometer, dropping funnel and condenser tube, first add 144g of 50wt% n-butyraldehyde solution accurately measured, start stirring and heat up to 90°C, then stir for 1.5 hours 120g of ethylenediamine and 110g of 30wt% formaldehyde solution were dropped into the container simultaneously for reaction, and then reacted for 1 hour after the addition, and then the reaction solution was cooled to room temperature; then,

[0032] (2) Add 1072 g of TMP to the reaction solution obtained in (1) under stirring, and stir to raise the temperature to 110° C., carry out the reaction for 2 hours, and then cool the reaction solution to room temperature; then,

[0033] (3) Heating the reactant to 90° C. under stirring, then continuously adding 250 g of 30 wt % formaldehyde solution to the reaction solution obtained in (2) within 1.5 hours for reaction, and continuing to stir for 2 hours after the addition to obtain bis Trimethylolprop...

Embodiment 3

[0036] (1) In the four-neck flask equipped with stirring, thermometer, dropping funnel and condenser tube, first add 144g of 50wt% n-butyraldehyde solution accurately measured, start stirring and be warming up to 30 ℃, under stirring again within 0.5 hours to 60g of 30wt% sodium hydroxide solution and 100g of 30wt% formaldehyde solution were added dropwise in the container to react, and then reacted for another 3 hours after feeding, and then the reaction solution was cooled to room temperature; then,

[0037] (2) Add 134 g of TMP to the reaction solution obtained in (1) under stirring, and stir to raise the temperature to 80° C., carry out the reaction for 1 h, and then cool the reaction solution to room temperature; then,

[0038] (3) Heating the reactant to 50° C. under stirring, then continuously adding 200 g of 30 wt % formaldehyde solution to the reaction solution obtained in (2) within 0.5 hours for reaction, and then stirring and reacting for 4 hours after the addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com