Process for preparing 3-hydroxy propionic aldehyde and 1, 3-propylene glycol

A technology of hydroxypropionaldehyde and propylene glycol, which is applied in the preparation of heterocyclic compounds, the reduction preparation of oxygen-containing functional groups, organic chemistry, etc., can solve the problems such as the loss of accelerator quaternary ammonium salts, and achieve shortened residence time, inhibition of dimerization, and high selectivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

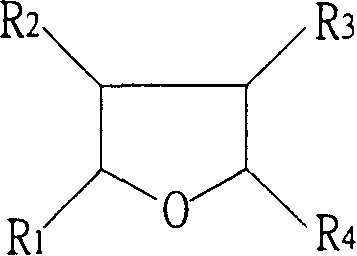

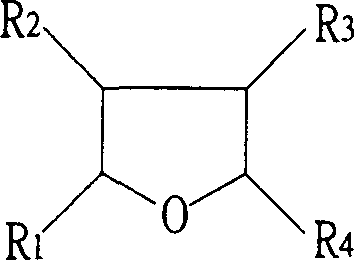

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 cobalt carbonyl catalyst

[0033] 0.04g Co(OH) 2 , 0.10g Co 2 (CO) 8 (for seeds), 1.80 g of deionized water and 200 ml of THF were put into a 300 ml autoclave. React at 120°C and 10MPa synthesis gas for 3 hours. Take a small amount of still liquid and use iodine to oxidize Co 2 (CO) 8 The volume of CO released, determine the Co 2 (CO) 8 production volume. The analysis results showed that Co(OH) 2 Has been fully converted to Co 2 (CO) 8 . co 2 (CO) 8 The concentration is 0.025M.

Embodiment 2

[0034] The preparation of embodiment 2 HPA

[0035] Prepared Co according to Example 1 2 (CO) 8 After the catalyst, the temperature of the reactor was lowered to 80°C, and 10g of ethylene oxide was added, at 12MPa, CO / H 2 =React for 60 minutes under the condition of 1:1, and take samples for analysis after cooling. The ethylene oxide conversion was 64% and the HPA selectivity was 76%. The main by-products are acetaldehyde and acrolein.

Embodiment 3

[0037] Change reaction temperature to be 90 ℃, all the other conditions are the same as embodiment 2. Analysis showed 100% conversion of ethylene oxide and 68% selectivity to HPA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com