Method for synthesizing isobutyraldehyde catalyst by using methyl alcohol and ethanol in one step

A catalyst, isobutyraldehyde technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor catalyst stability and achieve good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

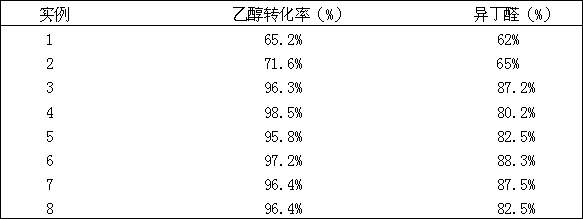

Examples

Embodiment 1

[0023] Example 1: 2.8 grams of sodium metavanadate was dissolved in 100 ml, 40.2 grams of ferric nitrate 9 water was dissolved in 50 ml of deionized water, and 3 g of citric acid was added. Then the two solutions were mixed, stirred at 80°C to evaporate the solvent, dried at 110°C for 12 hours, and then calcined in a muffle furnace at 500°C for 4 hours to prepare the catalyst.

Embodiment 2

[0024] Example 2: 5.4 grams of sodium metavanadate was dissolved in 100 ml, 30.2 grams of ferric nitrate 9 water was dissolved in 50 ml of deionized water, and 6 g of citric acid was added. Then the two solutions were mixed, stirred at 60°C to evaporate the solvent, dried at 110°C for 12 hours, and then calcined at 500°C for 4 hours in a muffle furnace to prepare the catalyst.

Embodiment 3

[0025] Example 3: 7.7 grams of ammonium metavanadate was dissolved in 100 ml, 20.0 grams of ferric nitrate 9 water was dissolved in 50 ml of deionized water, and 6 g of citric acid was added. Then the two solutions were mixed, stirred at 60°C to evaporate the solvent, dried at 110°C for 12 hours, and then calcined in a muffle furnace at 550°C for 4 hours to prepare the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com