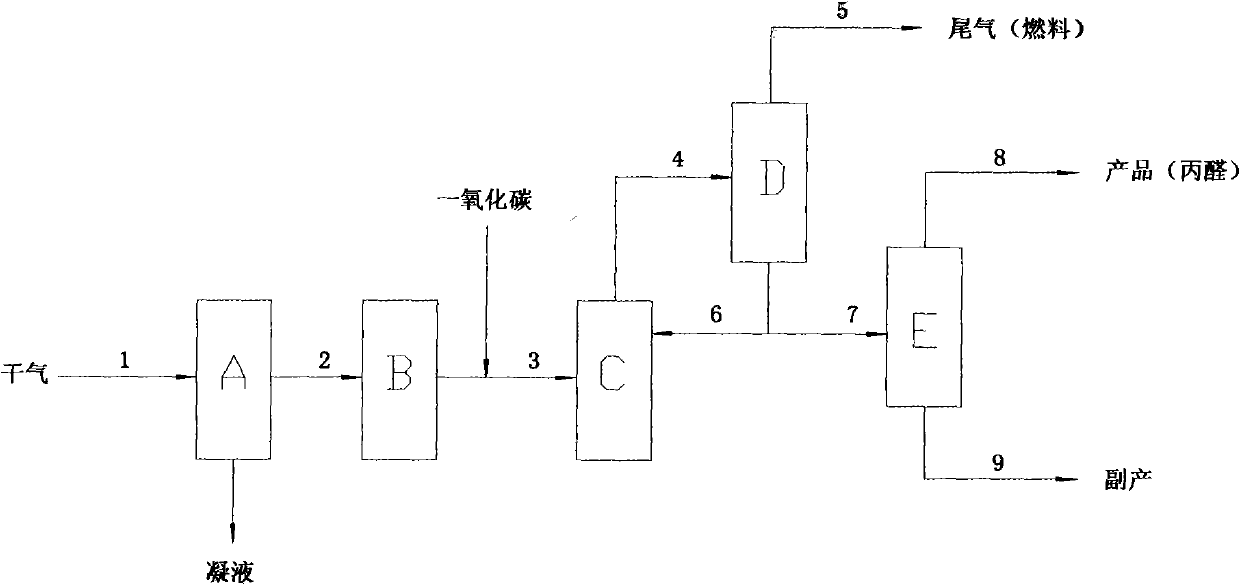

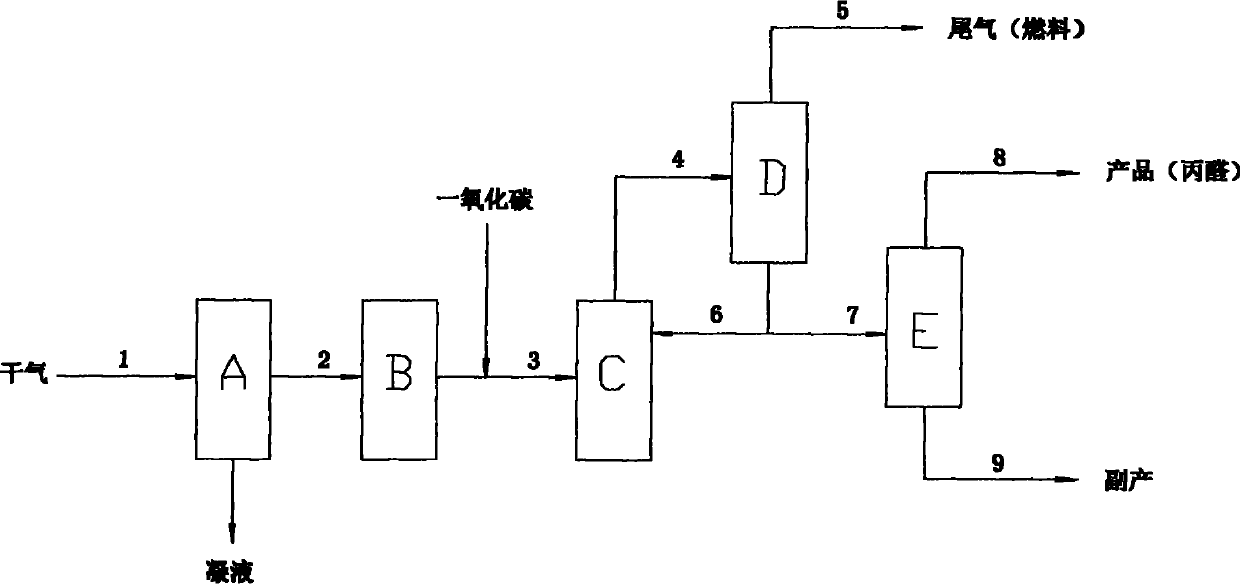

Method for preparing propionic aldehyde from ethylene in refinery dry gas

A refinery dry gas, ethylene technology, applied in the direction of carbon monoxide reaction preparation, organic chemistry, etc., can solve the problem of failure to provide, and achieve the effects of small equipment investment, simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the first step, the refinery dry gas with a pressure of 0.7Mpa is increased to 2.3Mpa through a compression system to form a high-pressure refinery dry gas.

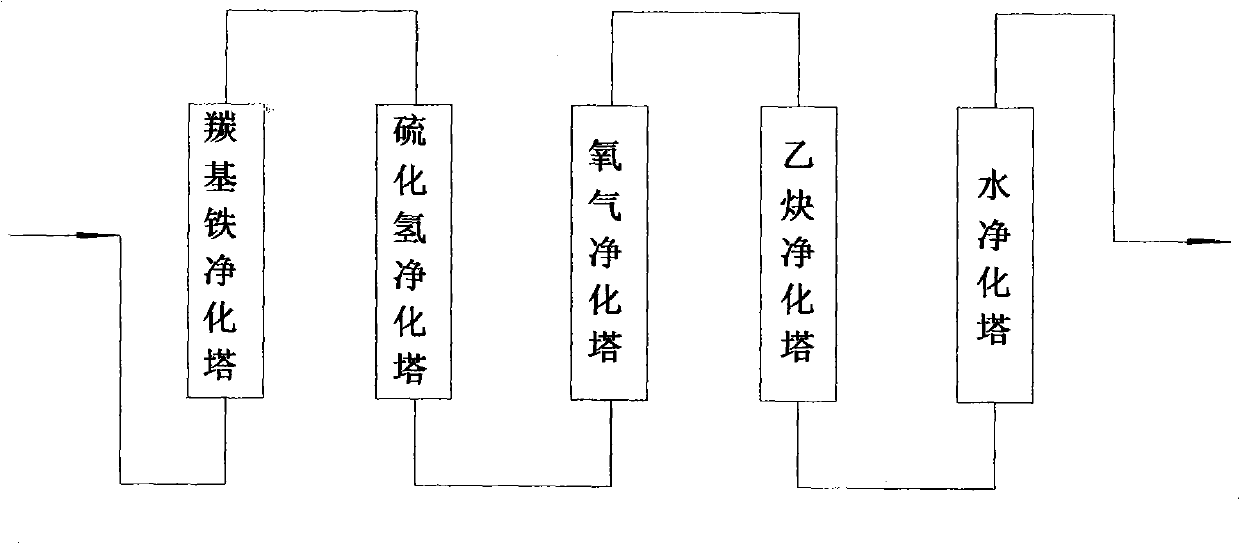

[0034]In the second step, the refinery dry gas containing 12.5% (molar content) of ethylene, 26% (molar content) of hydrogen, and methane, ethane, nitrogen, a small amount of propane, propylene, carbon dioxide, etc. is controlled by a flow meter at a rate of 5000ml / min. The flow rate passes through the purification device, and the refinery dry gas contains 10ppm carbonyl iron, 150ppm hydrogen sulfide, 70ppm oxygen, 3000ppm acetylene and 3000ppm water. The purification unit consists of five fixed-bed reactors connected in series, and each fixed-bed reactor can control the temperature independently. They are carbonyl iron purification tower, hydrogen sulfide purification tower, oxygen purification tower, acetylene purification tower and water purification tower. The carbonyl iron purification tower is equipped...

Embodiment 2

[0038] In the first step, the refinery dry gas with a pressure of 0.7Mpa is increased to 1.5Mpa through a compression system to form a high-pressure refinery dry gas.

[0039] In the second step, the refinery dry gas containing 12.5% (molar content) of ethylene, 26% (molar content) of hydrogen, and methane, ethane, nitrogen, a small amount of propane, propylene, carbon dioxide, etc. is controlled by a flow meter at a rate of 4000ml / min. The flow rate passes through the purification device, and the refinery dry gas contains 10ppm carbonyl iron, 150ppm hydrogen sulfide, 70ppm oxygen, 3000ppm acetylene and 3000ppm water. The purification unit consists of five fixed-bed reactors connected in series, and each fixed-bed reactor can control the temperature independently. They are carbonyl iron purification tower, hydrogen sulfide purification tower, oxygen purification tower, acetylene purification tower and water purification tower. The carbonyl iron purification tower is equippe...

Embodiment 3

[0043] In the first step, the refinery dry gas with a pressure of 0.7Mpa is increased to 1.8Mpa through a compression system to form a high-pressure refinery dry gas.

[0044] In the second step, the refinery dry gas containing 10.5% (molar content) of ethylene, 23% (molar content) of hydrogen, and methane, ethane, nitrogen, a small amount of propane, propylene, carbon dioxide, etc. is controlled by a flow meter at a rate of 5000ml / min. The flow rate passes through the purification device, and the dry gas of the refinery contains 20ppm carbonyl iron, 120ppm hydrogen sulfide, 50ppm oxygen, 3100ppm acetylene, and 3500ppm water. The purification unit consists of five fixed-bed reactors connected in series, and each fixed-bed reactor can control the temperature independently. They are carbonyl iron purification tower, hydrogen sulfide purification tower, oxygen purification tower, acetylene purification tower and water purification tower. The carbonyl iron purification tower is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com