Technical method for producing propyl aldehyde through hydroformylation of ethylene

A technology of ethylene hydroformylation and propionaldehyde, which is applied in the field of treatment of propionaldehyde rectification still liquid, which can solve the problems of increasing the difficulty of impurity polymer treatment, increasing the energy consumption load of rectification kettle, affecting the quality of rectification propionaldehyde, etc. problems, to achieve the effect of improving the process grade, reducing energy consumption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

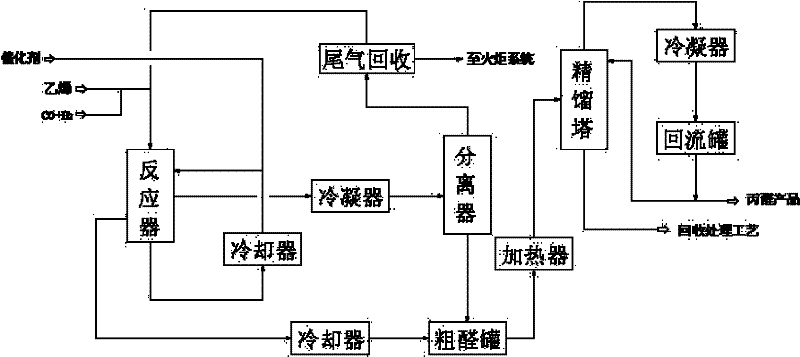

[0032] Such as figure 1 , feed gas (ethylene, CO and H 2 mixture) into the reactor, under the action of a water-soluble rhodium-phosphine complex catalyst, propionaldehyde is generated, the crude propionaldehyde is heated to 45-50°C by a heater, and then sent to the rectification tower, and propionaldehyde is discharged from the top of the tower at a temperature of 48°C , the temperature of the tower kettle is 85 ~ 125 ℃, and the kettle liquid reaches the recycling process.

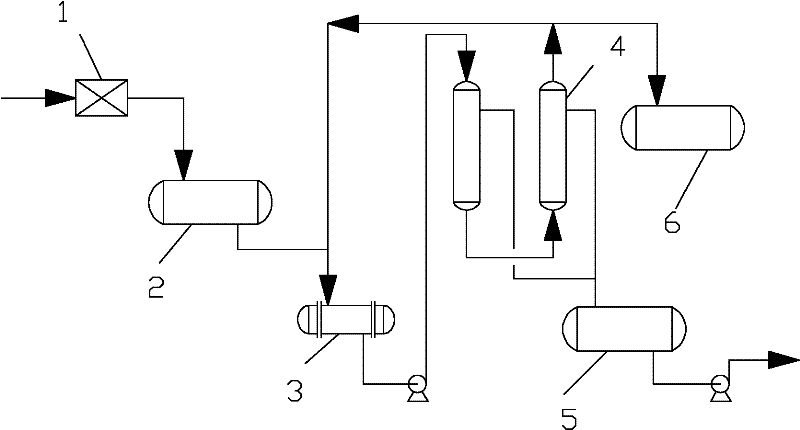

[0033] Such as figure 2 , the still liquid from the propionaldehyde rectification tower is 90°C, after being coarsely filtered by the filter screen of filter 1, after settling in the buffer tank 2, it is cooled to 10°C through the cooler 3, the water content in the still liquid is 90%, and the water content of 20 nm is selected. Aperture membrane tube, 0.38 MPa pressure, measured permeation flux after membrane separator 4 is 1620 kg / m 2 h, the water content of the permeate is 98%, the water content of...

Embodiment 2

[0035] This practical example is the same as Example 1, the difference is that the rectification still liquid is cooled to 45 ° C, the water content in the still liquid is 64%, a 200 nm aperture membrane tube is selected, and the pressure is 0.1 MPa. After membrane separation, the side part is concentrated The membrane is circulated, and a small part is taken out to the waste liquid tank 6 to remove impurity components. Water molecules pass through the ceramic membrane depermeate collection tank 5 and are pumped to the reactor. The measured permeation flux is 2220 kg / m 2 h, the water content of the permeate is 96.5%, the measured water content of the concentrated side is 7%, and the calculated water recovery rate is 96%.

Embodiment 3

[0037] This practical example is the same as Example 1, except that the rectification still liquid is cooled to 60°C, the water content in the still liquid is 42%, a 50 nm aperture membrane tube is selected, and the pressure is 0.6 MPa. After membrane separation, the side part is concentrated The membrane is circulated, and a small part is taken out to the waste liquid tank 6 to remove impurity components. Water molecules pass through the ceramic membrane depermeate collection tank 5 and are pumped to the reactor. The measured permeation flux is 1680 kg / m 2 h, the water content of the permeate is 97%, the water content of the concentrated side is 4%, and the calculated water recovery rate is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com