Method for separating and reclaiming acrolein

A technology for acrolein and hydroxypropionaldehyde, which is applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of high operating cost of thin film evaporator condenser, difficulty in polymerization and recovery of acrolein, and reduction of acrolein recovery rate. , to achieve the effect of easy implementation, lower operating temperature, and lower raw material consumption quota

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

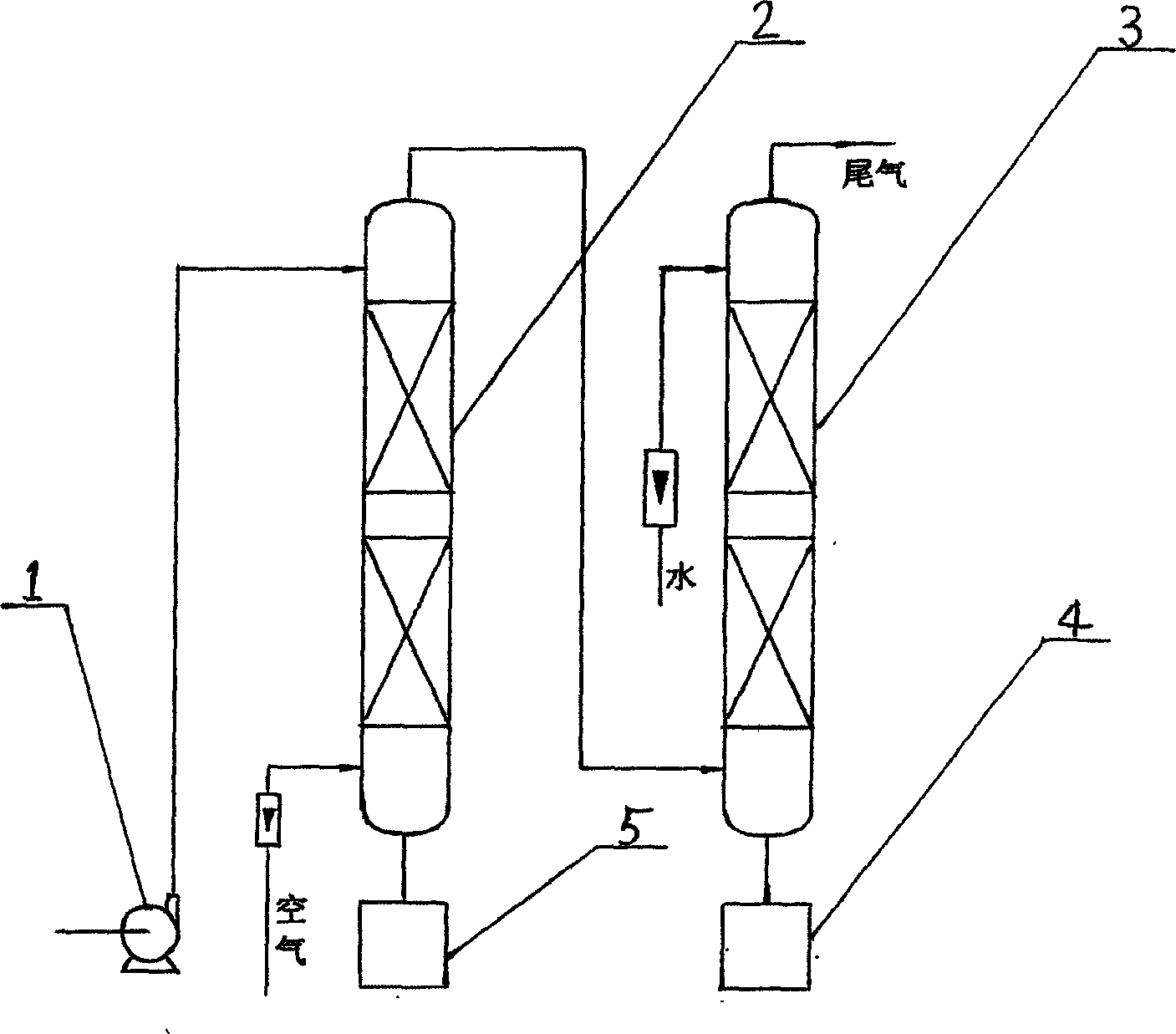

Embodiment 1

[0012] In this embodiment, the acrolein hydration liquid containing 4.5% (mass) of acrolein is continuously poured into the top of the dealdehyde tower [2] with the feed pump [1], and the tower kettle of the dealdehyde tower [2] is preheated to 52 ℃, and the metered inert gas is introduced into the bottom of the dealdehyde tower [2], the gas-liquid ratio is 150-180:1, the number of plates of the de-aldehyde tower is 8-12, and it is operated under normal pressure. The acrolein content of the final 3-hydroxypropanal aqueous solution dropped from the original 4.5% by mass to 0.3% by mass, and it entered the dealdehyde solution storage tank [5] as a raw material for hydrogenation of 3-hydroxypropanal. The acrolein extracted through the gas enters the bottom of the acrolein absorption tower [3] from the top of the dealdehyde tower [2] along with the inert gas, and the top of the absorption tower [3] is sprayed with absorbed water cooled to 5°C after metering, absorbing The ratio of...

Embodiment 2

[0014] The difference between this example and Example 1 is that the acrolein hydration liquid containing 5.5% (mass) of acrolein is continuously poured into the top of the dealdehyde tower [2] with the feed pump [1], and the dealdehyde tower [2] The tower kettle is preheated to 56° C., the number of trays of the dealdehyde tower [2] is 10 to 14, the gas-liquid ratio of the inert gas fed into the tower kettle and the feed is 200 to 220:1, operated under normal pressure, and the The acrolein content of the 3-hydroxypropionaldehyde aqueous solution after the aldehyde has dropped from the original 5.5 mass % to 0.5 mass %, and it enters the dealdehyde solution storage tank [5] as a raw material for the hydrogenation of 3-hydroxypropionaldehyde. The acrolein extracted through the gas enters the bottom of the acrolein absorption tower [3] from the top of the dealdehyde tower [2] along with the inert gas, and the top of the absorption tower [3] is sprayed with absorbed water cooled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com