Method for separating and reclaiming acrolein

A technology of acrolein and hydroxypropionaldehyde, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of high operating cost of thin-film evaporator condenser, difficulties in acrolein polymerization and recovery, and low recovery rate of acrolein , to achieve the effects of easy realization, lower operating temperature, and lower raw material consumption quota

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

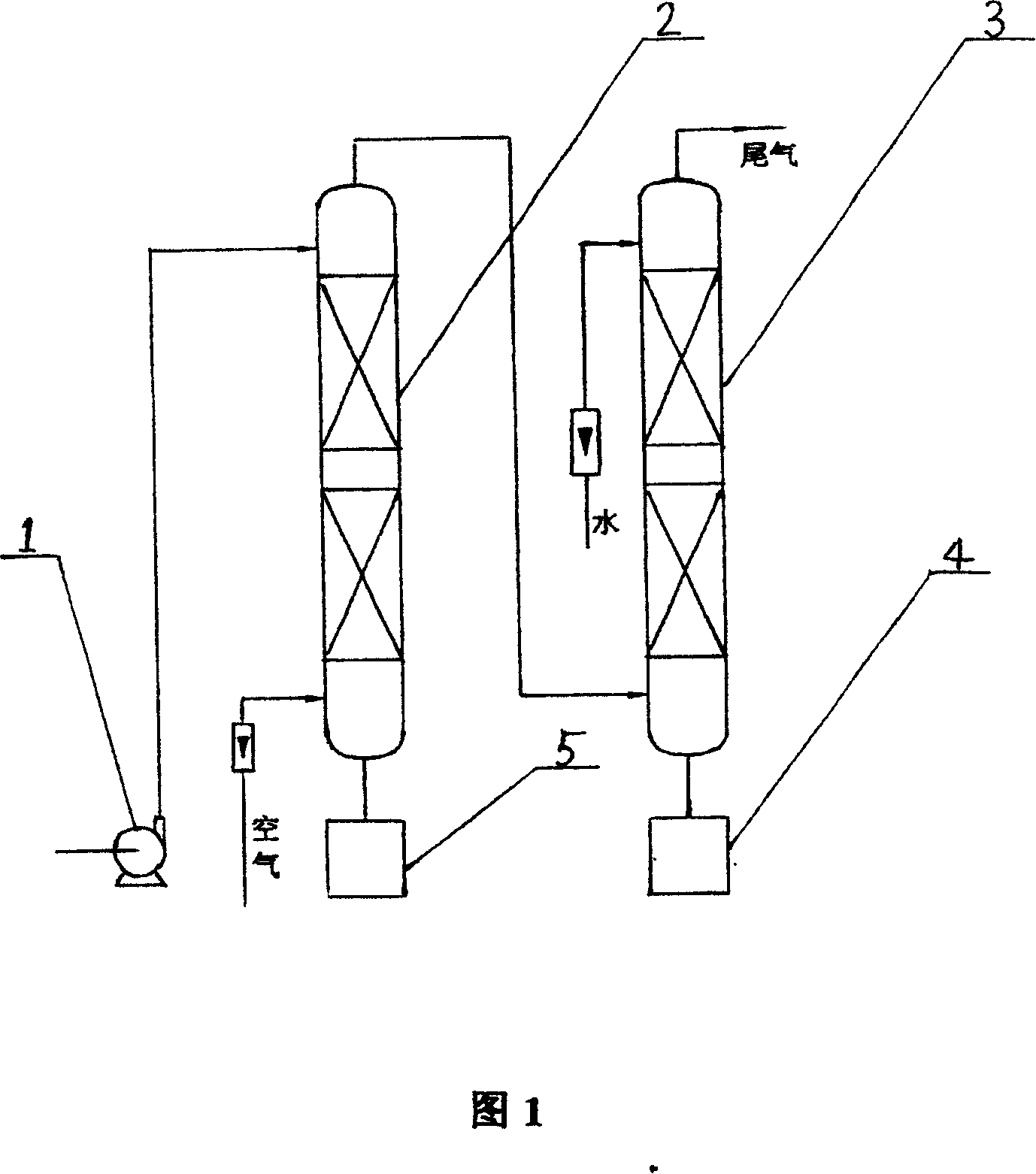

Embodiment 1

[0011] In this embodiment, the acrolein hydration liquid containing 4.5% (mass) of acrolein is continuously poured into the top of the dealdehyde tower [2] with the feed pump [1], and the tower kettle of the dealdehyde tower [2] is preheated to 52 ℃, and the metered inert gas is introduced into the bottom of the dealdehyde tower [2], the gas-liquid ratio is 150-180: l, the number of trays of the de-aldehyde tower is 8-12, and it is operated under normal pressure. The acrolein content of the final 3-hydroxypropanal aqueous solution dropped from the original 4.5% by mass to 0.3% by mass, and it entered the dealdehyde solution storage tank [5] as a raw material for hydrogenation of 3-hydroxypropanal. The acrolein extracted through the gas enters the bottom of the acrolein absorption tower [3] from the top of the dealdehyde tower [2] along with the inert gas, and the top of the absorption tower [3] is sprayed with absorbed water cooled to 5°C after metering, absorbing The ratio of...

Embodiment 2

[0013] The difference between this example and Example 1 is that the acrolein hydration liquid containing 5.5% (mass) of acrolein is continuously poured into the top of the dealdehyde tower [2] with the feed pump [1], and the dealdehyde tower [2] The tower kettle is preheated to 56° C., the number of trays of the dealdehyde tower [2] is 10 to 14, the gas-liquid ratio of the inert gas fed into the tower kettle and the feed is 200 to 220:1, operated under normal pressure, and the The acrolein content of the 3-hydroxypropionaldehyde aqueous solution after the aldehyde has dropped from the original 5.5 mass % to 0.5 mass %, and it enters the dealdehyde solution storage tank [5] as a raw material for the hydrogenation of 3-hydroxypropionaldehyde. The acrolein extracted through the gas enters the bottom of the acrolein absorption tower [3] from the top of the dealdehyde tower [2] along with the inert gas, and the top of the absorption tower [3] is sprayed with absorbed water cooled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com