Ohmic contact of thin film solar cell

a solar cell and thin film technology, applied in the field of contact structures, can solve the problems of reducing the efficiency of the solar cell, degrading the electrical contact between the absorber poor ohmic contact between the molybdenum layer and the absorber layer, so as to reduce the chalcogenization of the transition metal, reduce the contact resistance, and reduce the effect of contact resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]As stated above, the present disclosure relates to low resistance contact structures between a transition metal layer and a semiconductor chalcogenide material, and methods of manufacturing the same, which are now described in detail with accompanying figures. It is noted that like reference numerals refer to like elements across different embodiments.

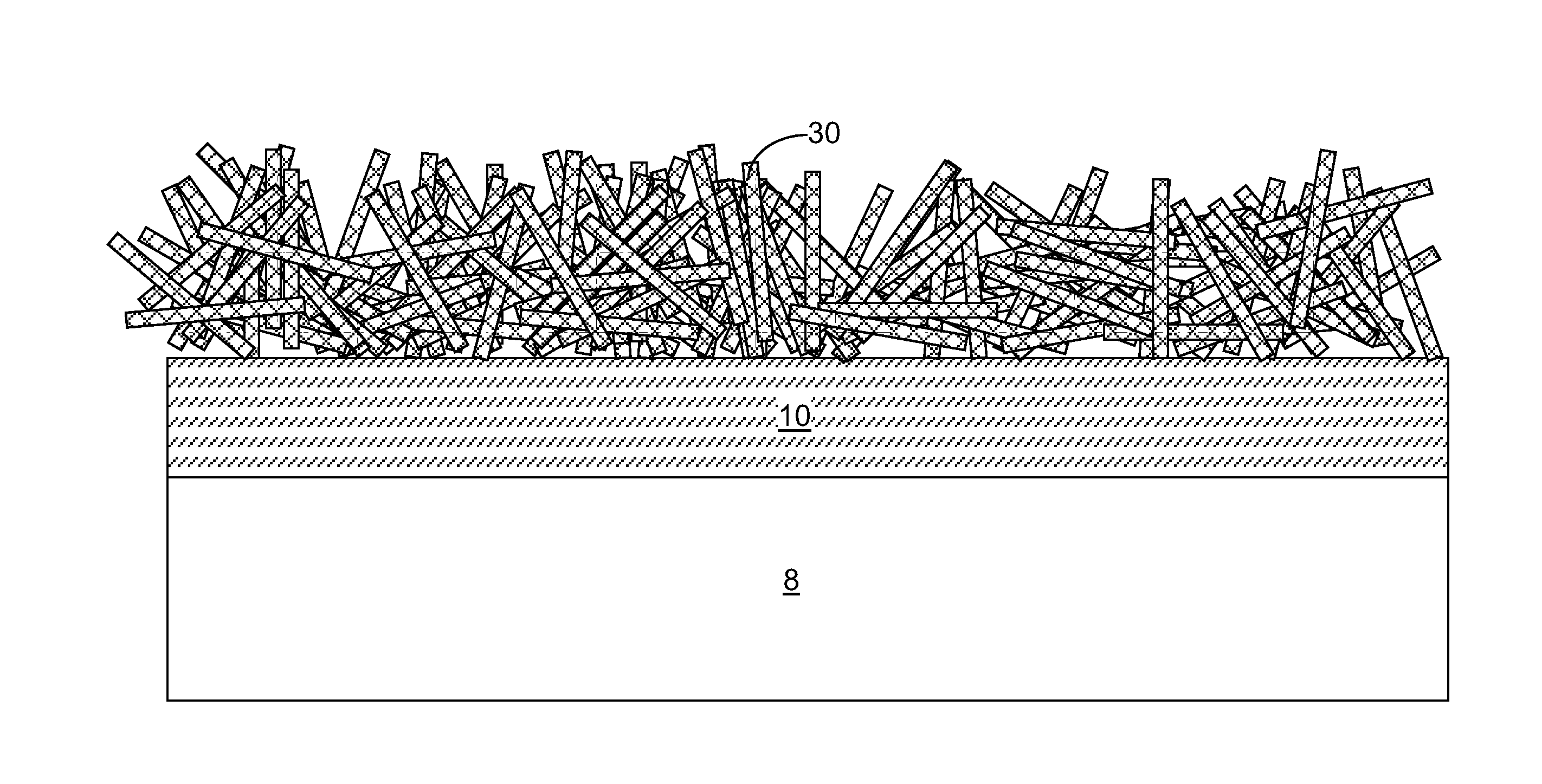

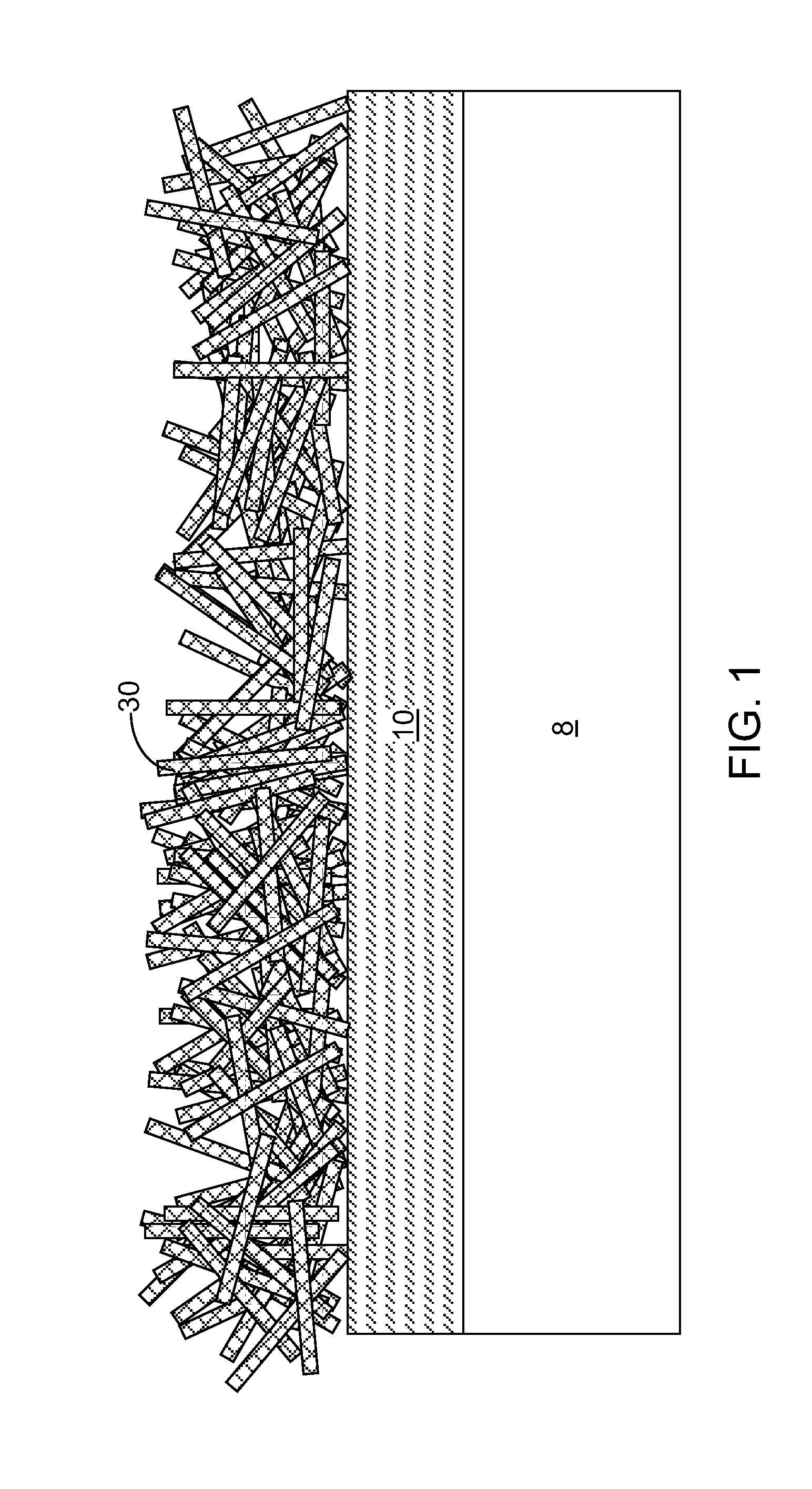

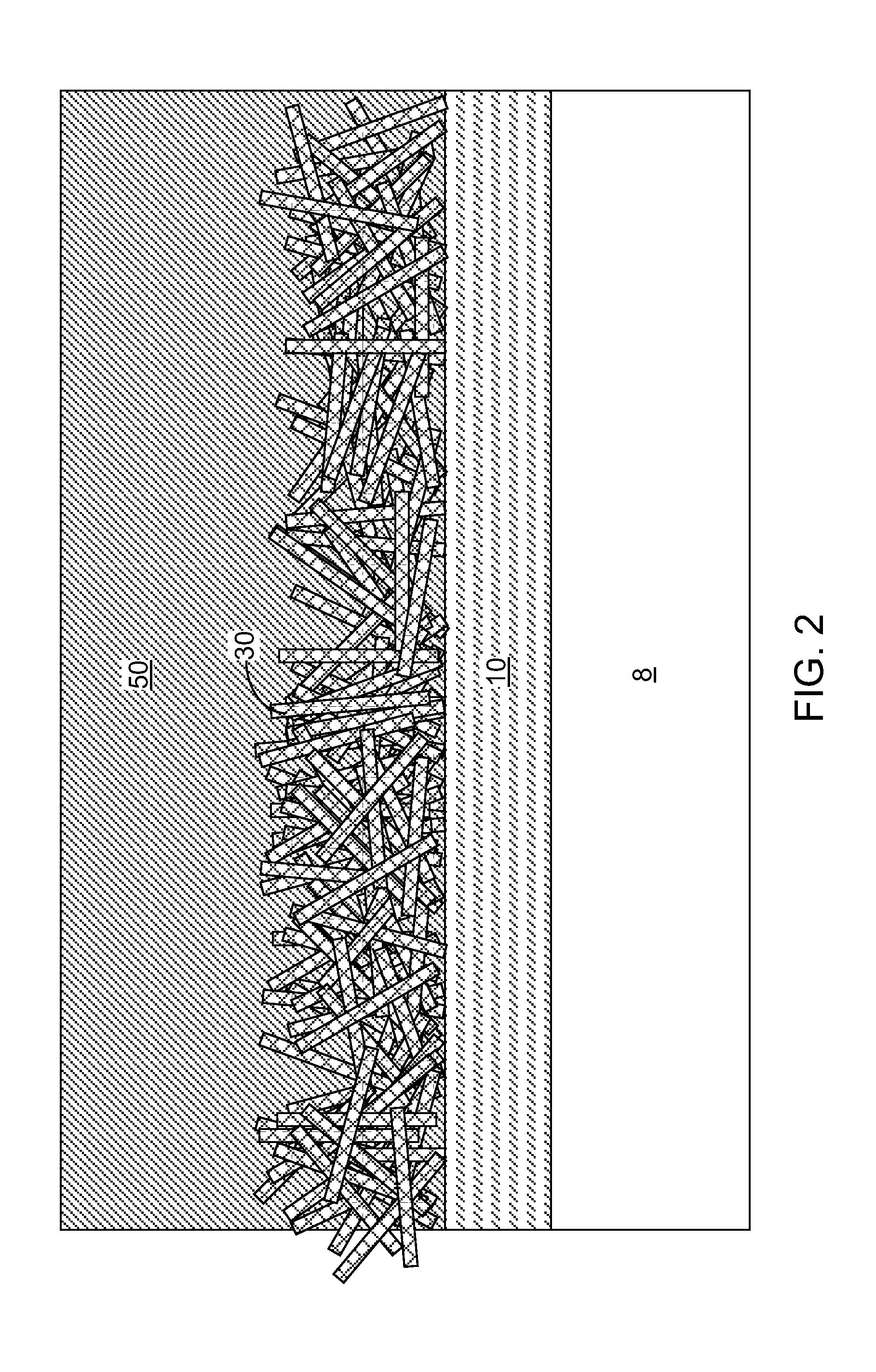

[0016]Referring to FIG. 1, a first exemplary structure according to a first embodiment of the present disclosure includes a transition metal layer 10 formed on a substrate 8. In one embodiment, the substrate 8 can be an insulator substrate including a dielectric material such as glass or a plastic material. In another embodiment, the substrate 8 can be a metallic substrate including a diffusion barrier layer on the top surface thereof. The diffusion barrier layer can be a metallic nitride layer such as tantalum nitride or titanium nitride, and prevents diffusion of metallic materials from a lower portion of the substrate 8 to a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com