Stannite structure Cu2FeSnSe4 powder material and liquid phase preparation method thereof

A kesterite structure and powder material technology, applied in the field of materials for solar photovoltaic cells, can solve the problems of complex element ratio and multi-layer structure, limit the industrialization of CIGS thin film solar cells, etc., and achieve easy control of product properties and low cost. , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

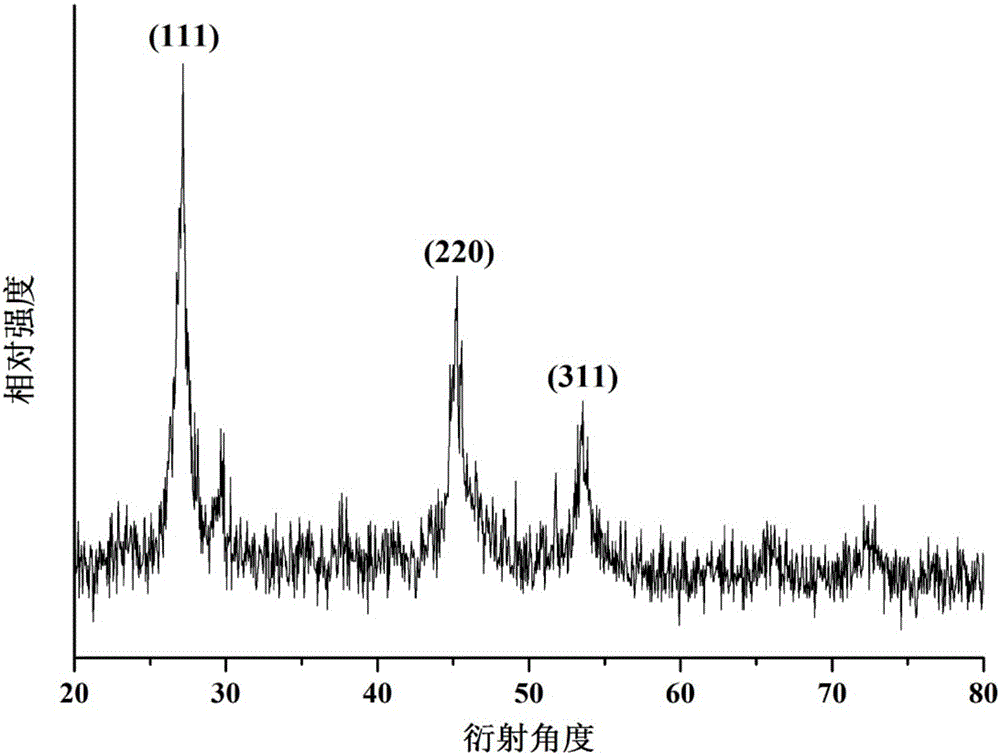

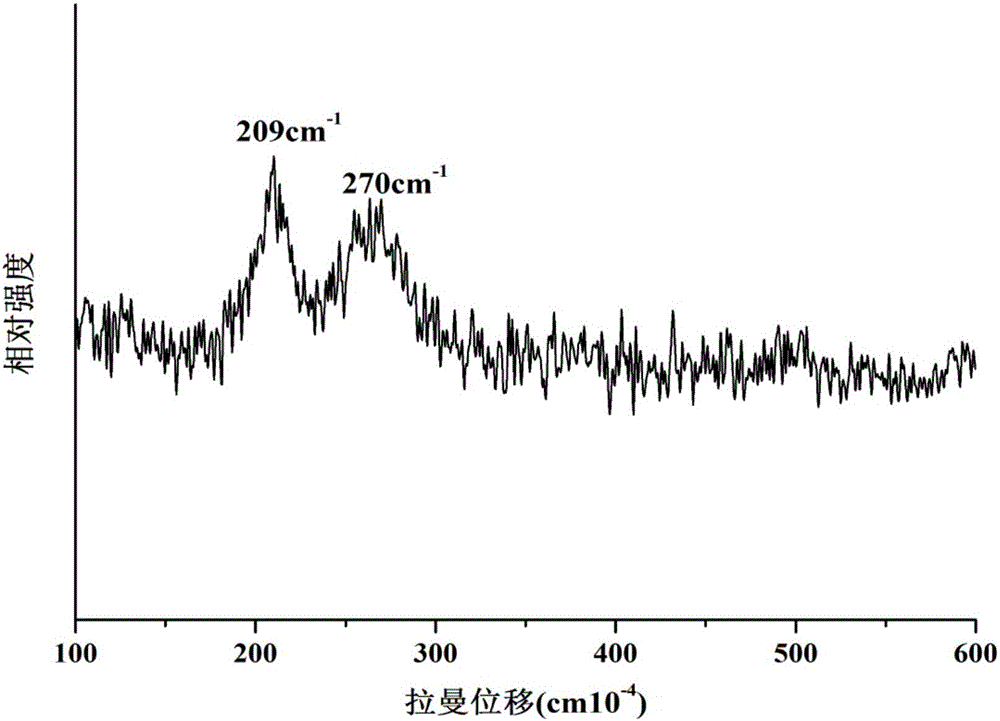

[0025] Weigh 4mmolCuCl 2 2H 2 O, 2 mmol FeCl 3 ·6H 2 O, 2mmolSnCl 4 ·5H 2 0, 8mmol selenium powder is put into a round-bottomed three-necked flask, add triethylenetetramine 30ml, leave it for 3-5 minutes, obtain a uniform light blue solution, feed nitrogen to do protective gas, and carry out stirring and condensing reflux, The round-bottomed three-neck flask was heated to 230°C in a constant temperature oil bath and kept for 4 hours, then cooled to room temperature naturally, washed with absolute ethanol and deionized water for 5 times, then filtered, and placed in a dry box at 90°C ℃ dried for 2h to obtain a black solid.

Embodiment 2

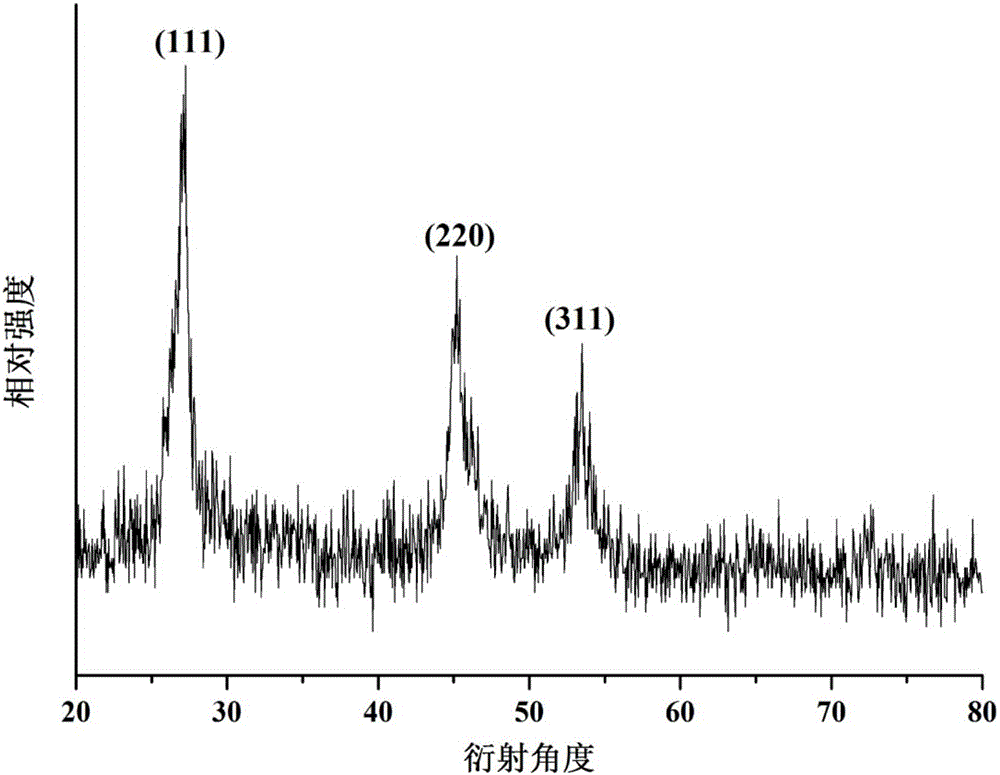

[0027] Weigh 4mmolCuCl 2 2H 2 O, 2 mmol FeCl 3 ·6H 2 O, 2mmolSnCl 4 ·5H 2 0, 8mmol selenium powder is put into a round-bottomed three-necked flask, add triethylenetetramine 30ml, leave it for 3-5 minutes, obtain a uniform light blue solution, feed nitrogen to do protective gas, and carry out stirring and condensing reflux, The three-necked round-bottom flask was heated to 200°C in a constant temperature oil bath, and kept for 2 hours, then cooled to room temperature naturally, washed with absolute ethanol and deionized water for 3 times, then filtered, and placed in a dry box for 60 It was dried at ℃ for 6h to obtain a black solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com