A method for separating aluminum and iron by suspension roasting of high-iron bauxite

A high-iron bauxite and suspension roasting technology is applied in the field of suspension roasting of high-iron bauxite to separate aluminum and iron, and can solve the problems of inability to popularize and apply, low separation efficiency, and inability to effectively separate aluminum and iron.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

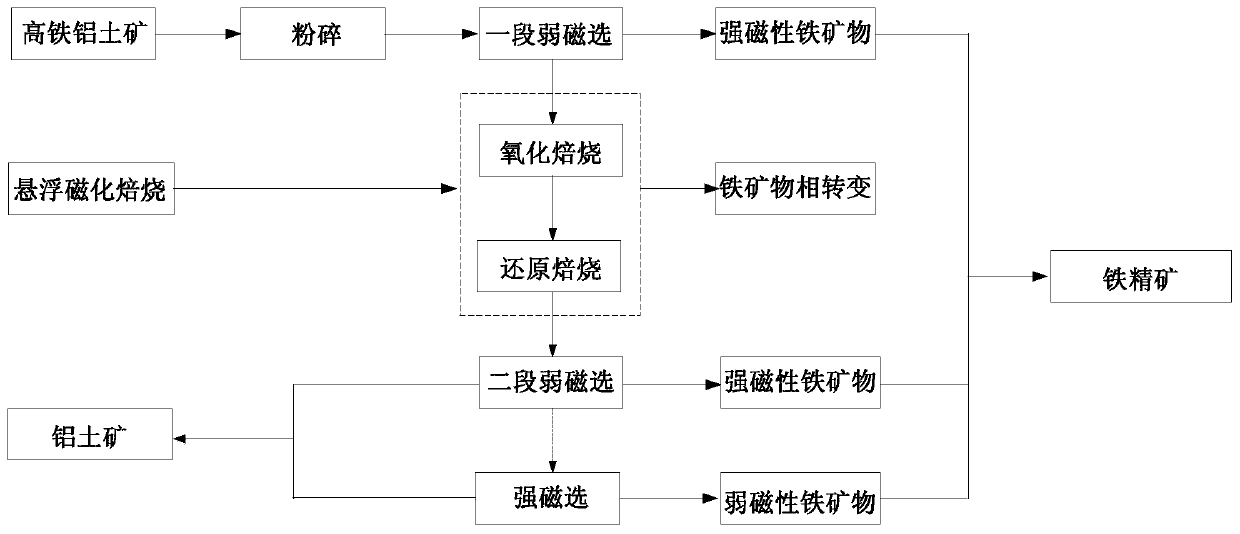

[0029] Process such as figure 1 shown;

[0030] Crushing the high-iron bauxite to a particle size of 5-20mm, and then grinding the ore to a particle size of -0.074mm accounts for 50% of the total weight;

[0031] The ore powder is subjected to a stage of weak magnetic separation, with a magnetic field strength of 1000Oe, to obtain a stage of magnetic separation concentrate and a stage of magnetic separation tailings;

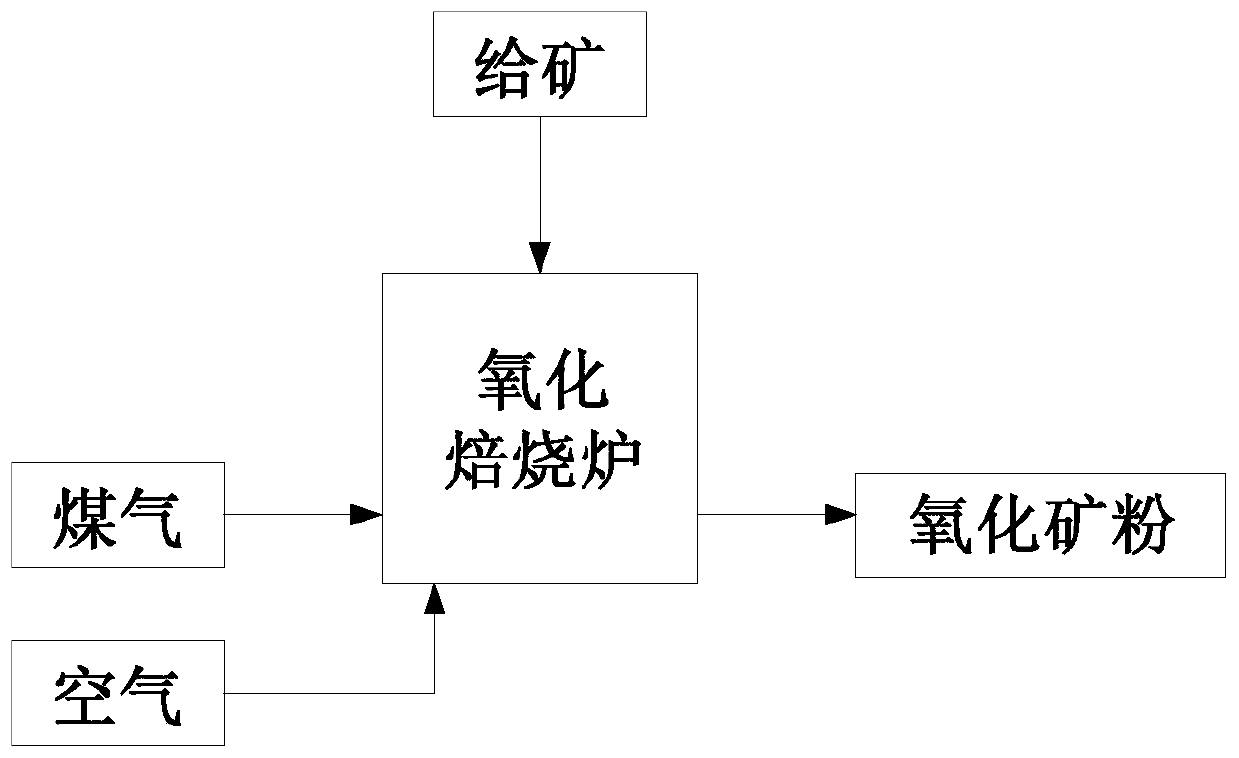

[0032] Put a section of magnetic separation tailings in a roasting furnace, feed gas and air, make a section of magnetic separation tailings in a suspended state, and oxidize and roast at 800°C for 20 minutes to convert iron minerals into Fe 2 o 3 , and remove water and other volatile matter to obtain oxidized ore powder; the flow rate of air and gas is 15m per ton of magnetic separation tailings 3 / h; oxidation process such as figure 2 shown;

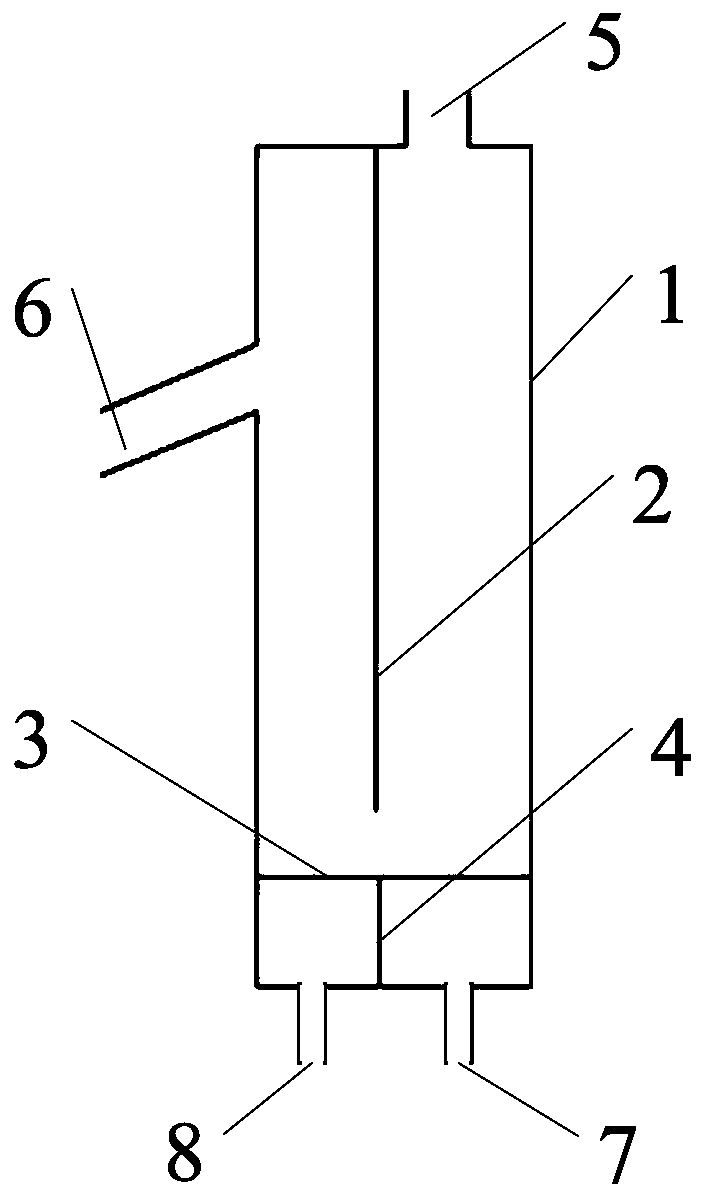

[0033] Using a reduction roaster, the structure is as follows image 3 As shown, the housing is equipped with a...

Embodiment 2

[0038] Method is with embodiment 1, and difference is:

[0039] (1) crushing the high-iron bauxite to a particle size of 5-20 mm, and then grinding the ore to a particle size of -0.074 mm to account for 60% of the total weight;

[0040] (2) The magnetic field strength of a section of weak magnetic separation is 2000Oe;

[0041](3) Carry out oxidative roasting at 950°C for 5 minutes, and the flow rate of air and gas is 20m per ton of first-stage magnetic separation tailings. 3 / h;

[0042] (4) The reduction roasting temperature is 700°C, the time is 3min, and the reducing gas is H 2 , the flow rate of reducing gas is H 2 The total amount is 5m 3 / h; the ratio of nitrogen and reducing gas is 5:1;

[0043] (5) The magnetic field strength of the second section of weak magnetic separation is 2000Oe, and the magnetic field strength of strong magnetic separation is 10000Oe;

[0044] (6) the iron grade TFe of the high-iron bauxite that adopts is 28%, contains Al by weight percen...

Embodiment 3

[0046] Method is with embodiment 1, and difference is:

[0047] (1) crushing the high-iron bauxite to a particle size of 5-20 mm, and then grinding the ore to a particle size of -0.038 mm, accounting for 80% of the total weight;

[0048] (2) The magnetic field strength of a section of weak magnetic separation is 1400Oe;

[0049] (3) Oxidize and roast at 850°C for 15 minutes, and the flow rate of air and gas is 5m per ton of magnetic separation tailings. 3 / h;

[0050] (4) The reduction roasting temperature is 500°C, the time is 8 minutes, the reduction gas is coal gas, and the flow rate of the reduction gas is based on the amount of CO and H introduced per ton of oxidized ore powder. 2 The total amount is 15m 3 / h; the ratio of nitrogen and reducing gas is 3:1;

[0051] (5) The magnetic field strength of the second stage of weak magnetic separation is 1400Oe, and the magnetic field strength of strong magnetic separation is 6000Oe;

[0052] (6) The iron grade TFe of the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com