Chloroacetamide herbicide capsule suspension and production method thereof

A technology of microcapsule suspension and chloroacetamide, which is applied in the fields of herbicides and algicides, preparation of microspheres, botany equipment and methods, etc. It can solve the problems of affecting drug efficacy, difficulty in adapting to different crops and environments, and difficulty in recycling Use and other problems to achieve the effect of stable reaction process, convenient adjustment and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0123] A preparation method of the above-mentioned chloroacetamide herbicide microcapsule suspension, specifically comprising the following reaction steps:

[0124] (1) According to the above a kind of chloroacetamide herbicide suspending agent, take by weighing chloroacetamide herbicide, isocyanate, polyurethane soft segment, chain extender, surfactant, defoamer, antifreeze, preservative , thickener and water, spare;

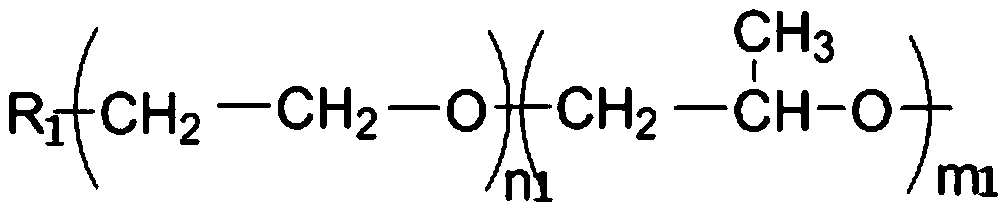

[0125] (2) Prepare the dispersed phase: mix the chloroacetamide herbicide, isocyanate and polyurethane soft segment evenly to obtain the dispersed phase;

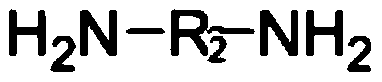

[0126] (3) Prepare the continuous phase: add the chain extender to water, stir evenly to prepare the continuous phase;

[0127] (4) Preparation of microcapsules: Put the dispersed phase and the continuous phase prepared above into the stirring tank respectively, and then use the injection pump to inject them according to the feed rate ratio of the dispersed phase and the continuous phase at 2:1-1:2 In the ...

Embodiment 1

[0133] A preparation method of acetochlor microcapsule suspension, specifically comprising the following reaction steps:

[0134] (1) Weigh 60g acetochlor, 2g toluene diisocyanate, 1.5g polyurethane soft segment PEG200, 1g chain extender CAED-900, 10g surfactant RH-208, 0.5g silicone defoamer, 5g glycerine Alcohol antifreeze agent, 2g Kathon preservative and 2g magnesium aluminum silicate thickener, and weigh the water of surplus by 100g total amount, standby;

[0135] (2) Prepare the dispersed phase: mix the above-mentioned weighed acetochlor, toluene diisocyanate, PEG200 evenly, and prepare the dispersed phase;

[0136] (3) Prepare the continuous phase: mix the above weighed chain extender CAED-900, silicone defoamer and water evenly to prepare the continuous phase;

[0137] (4) Preparation of microcapsules: the dispersed phase and the continuous phase prepared above are respectively loaded into a stirred tank, and the dispersed phase and the continuous phase are respective...

Embodiment 2

[0140] The 1.5 g polyurethane soft segment PEG200 used in the above-mentioned Example 1 was replaced with 5 g polyurethane soft segment PEG200, and other operating steps and technical parameters were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com