A kind of loratadine nano crystal and preparation method thereof

A loratadine and nanocrystal technology, which is applied in the field of pharmaceutical nanocrystals and their preparation, can solve the problems of difficulty in process control, generation of organic solvents, difficulty in large-scale production, etc., and achieves controllable preparation process and reduced energy consumption for homogenization. , the effect of narrow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

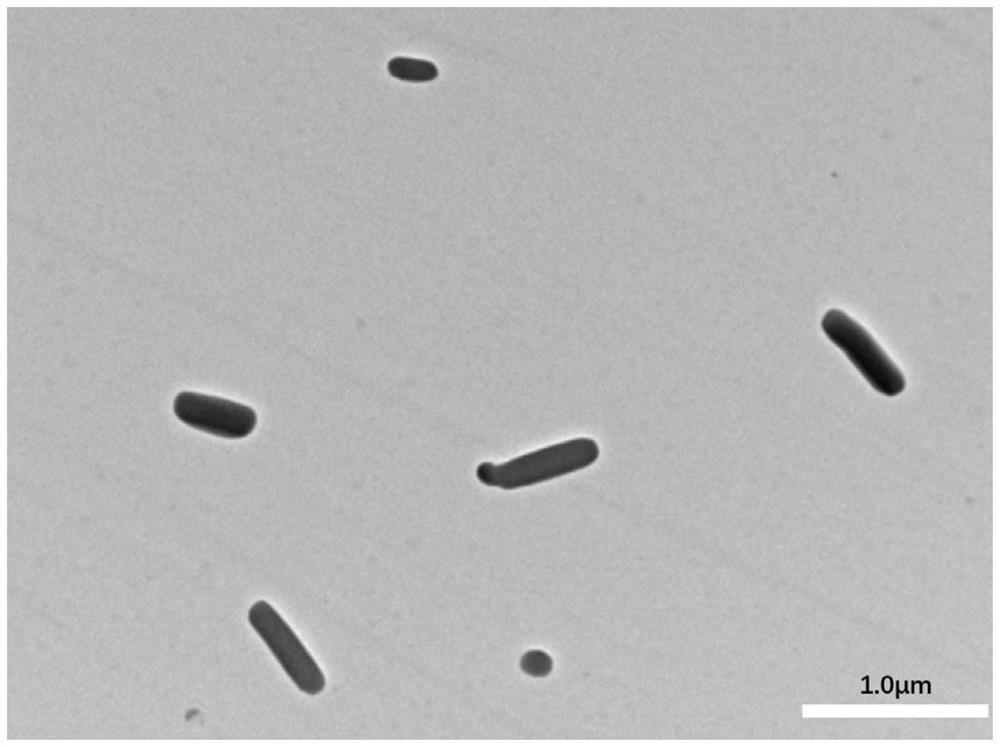

Embodiment 1

[0036] Weigh 1 part of Tween 80 and add it into 20ml of pure water, place it on a magnetic stirrer at 200rpm and stir until completely dissolved, weigh 5 parts of loratadine raw material, add the aqueous solution containing Tween 80 under stirring During the process, the stirring was continued for 5 minutes to disperse the loratadine in the aqueous stabilizer solution, and the high-speed shear was cut at 1000 rpm for 1 minute to obtain a coarse suspension. Pour the coarse suspension into the feed port of the high-pressure homogenizer, circulate 10 times at 400 bar, and then circulate 10 times at 1000 bar to obtain the loratadine suspension. Add lactose into the prepared loratadine nanosuspension, shake it to fully dissolve, place it in a refrigerator at -80°C for 12 hours, and then freeze it in a freeze dryer for 48 hours to obtain a plump and loose chloratadine. Ratadine nano crystals, the prepared loratadine nano crystals have a particle size of 758.4nm and a PDI of 0.248. ...

Embodiment 2

[0038] Weigh 20 parts of Poloxamer 188 and add it into 20ml of pure water, place it on a magnetic stirrer and stir at 1000rpm until completely dissolved, weigh 50 parts of loratadine raw material, add the poloxamer containing poloxamer under stirring In the aqueous solution of M188, continue to stir for 15 minutes to disperse loratadine in the aqueous solution of the stabilizer, and shear at 6000 rpm for 15 minutes with a high-speed shearer to obtain a coarse suspension. Pour the coarse suspension into the feed port of the high-pressure homogenizer, circulate 30 times at 1000 bar, and circulate 50 times at 2400 bar to obtain the loratadine suspension. Add lactose into the prepared loratadine nanosuspension, shake it to fully dissolve, place it in a refrigerator at -80°C for 12 hours, and then freeze it in a freeze dryer for 48 hours to obtain a plump and loose chloratadine. Ratadine nano crystals, the prepared loratadine nano crystals have a particle size of 593.2nm and a PDI ...

Embodiment 3

[0040]Weigh 20 parts of Poloxamer 188 and add it into 20ml of pure water, place it on a magnetic stirrer and stir at 1000rpm until completely dissolved, weigh 50 parts of loratadine raw material, add the poloxamer containing poloxamer under stirring In the aqueous solution of M188, continue to stir for 15 minutes to disperse loratadine in the aqueous solution of the stabilizer, and shear at 6000 rpm for 15 minutes with a high-speed shearer to obtain a coarse suspension. Pour the coarse suspension into the feed port of the high-pressure homogenizer, circulate 30 times at 600 bar, and circulate 50 times at 2200 bar to obtain the loratadine suspension. Add lactose into the prepared loratadine nanosuspension, shake it to fully dissolve, place it in a refrigerator at -80°C for 12 hours, and then freeze it in a freeze dryer for 48 hours to obtain a plump and loose chloratadine. Ratadine nano crystals, the prepared loratadine nano crystals have a particle size of 412.7nm and a PDI of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com