Preparation method of multi-arm star polyamide polymer

A polymer and multi-armed star technology, which is applied in the field of preparation of multi-armed star-shaped polyamide polymers, to achieve the effects of flexible and adjustable structure, mild reaction conditions, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

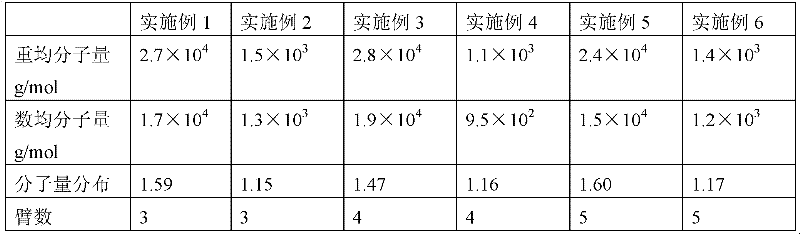

Embodiment 1

[0026] 0.03 mol of 1,2,4-benzenetricarboxylic anhydride, 15 mol of caprolactam, and 500 ml of deionized water (33% of the total feeding weight) were put into a 5L autoclave at one time. After repeated replacement of nitrogen three times, the nitrogen atmosphere in the reaction kettle was ensured. Then raise the temperature of the reactor to 240° C., adjust the pressure to be constant at 2.0 MPa, keep the temperature for 30 minutes, and turn on the stirring device of the reactor after the materials are completely melted. After reacting for 10 hours, release the pressure, and vacuumize to keep the pressure in the kettle lower than 1×10 -5 After MPa, keep the pressure constant for 20 minutes. Finally, high-pressure nitrogen was filled to make the pressure in the kettle reach 2.0MPa, and the polymer in the reactor was extruded, cooled with water, and then granulated, and vacuum-dried at 100°C for 24 hours to obtain three-armed star-shaped PA6. The characterization of this star p...

Embodiment 2

[0028] 0.36 mol of 1,2,4-benzenetricarboxylic anhydride, 15 mol of caprolactam, and 500 ml of deionized water (33% of the total feeding weight) were put into a 5L autoclave at one time. After repeated replacement of nitrogen three times, the nitrogen atmosphere in the reaction kettle was ensured. Then raise the temperature of the reactor to 240° C., adjust the pressure to be constant at 2.0 MPa, keep the temperature for 30 minutes, and turn on the stirring device of the reactor after the materials are completely melted. After reacting for 10 hours, release the pressure, and vacuumize to keep the pressure in the kettle lower than 1×10 -4 After MPa, keep the pressure constant for 20 minutes. Finally, high-pressure nitrogen was filled to make the pressure in the kettle reach 1.8MPa, and the polymer in the reactor was extruded and cooled with water, then granulated, and vacuum-dried at 100°C for 24 hours to obtain three-armed star-shaped PA6. The characterization of this star po...

Embodiment 3

[0030] 0.02 mol of pyromellitic dianhydride, 8 mol of aminoundecanoic acid, and 320 ml of deionized water (20% of the total feeding weight) were thrown into a 5L autoclave at one time. After repeated replacement of nitrogen three times, the nitrogen atmosphere in the reaction kettle was ensured. Then raise the temperature of the reactor to 230° C., adjust the pressure to be constant at 1.8 MPa, keep the temperature for 30 minutes, and turn on the stirring device of the reactor after the materials are completely melted. After reacting for 10 hours, release the pressure, and vacuumize to keep the pressure in the kettle lower than 1×10 -5 After MPa, keep the pressure constant for 20 minutes. Finally, high-pressure nitrogen was filled to make the pressure inside the kettle reach 2.0MPa. The polymer in the reactor was extruded and cooled with water, then granulated, and vacuum-dried at 100°C for 24 hours to obtain four-armed star-shaped PA11. The characterization of this star pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com