Preparation method and application of a fluorescent probe with controllable hydrophilicity and hydrophobicity

A hydrophobic and hydrophilic technology, used in fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve the problems of no preparation of nanomaterials, adverse effects on organisms, complex preparation process, etc., and achieve good applications Promising effect, low cytotoxicity, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

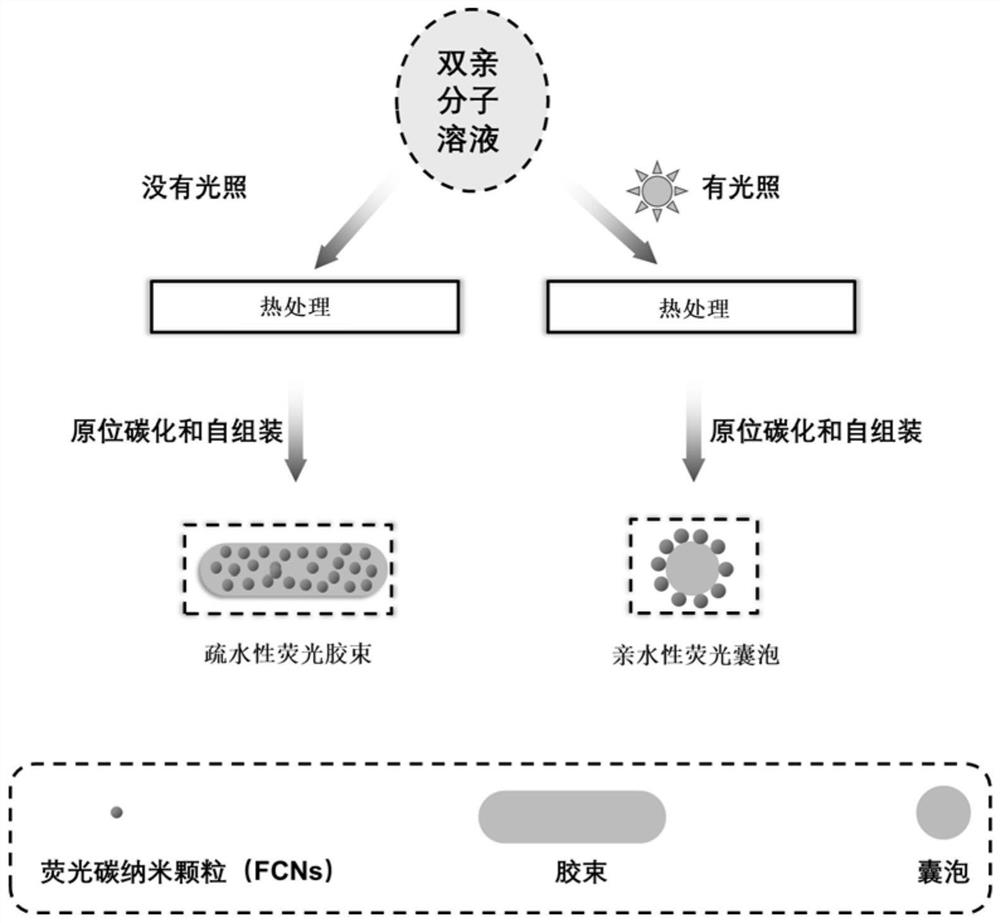

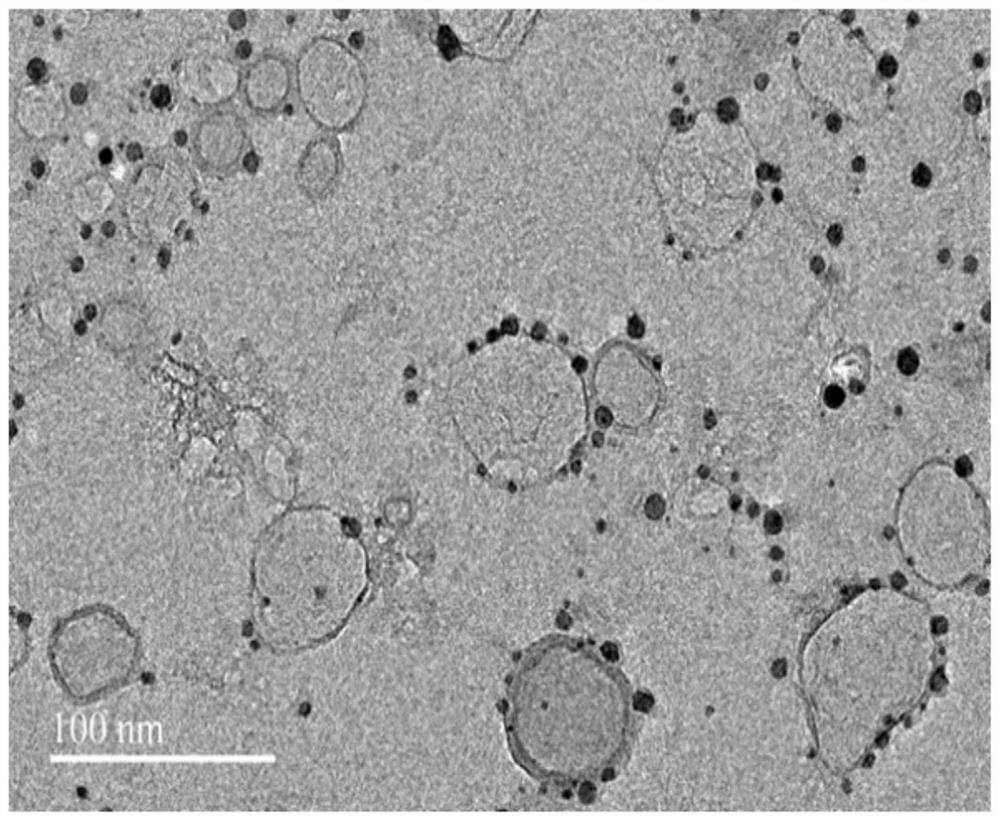

[0067] In this example, the hydrophilicity and hydrophobicity control of fluorescent vesicles and fluorescent micelles are realized by the following methods

[0068] (1) Mix nonanoic acid with water, the stirring speed is 100rpm, and the stirring time is 5min to obtain a nonanoic acid aqueous solution with a concentration of 60mM, and then carry out light pretreatment, the light wavelength is 600nm, the light time is 5h, and the reaction is carried out under stirring. The stirring speed is 500rpm, and the stirring time is 5h. After the reaction is completed, there is no separation, and then the rotary steaming is carried out. The rotary steaming temperature is 50°C, and the rotary steaming time is 2h. The ratio (volume ratio) is 2:1, the oscillation speed is 100rpm, the oscillation time is 6h, and the standing time is 20h, and hydrophilic fluorescent vesicles are obtained in the water intake system;

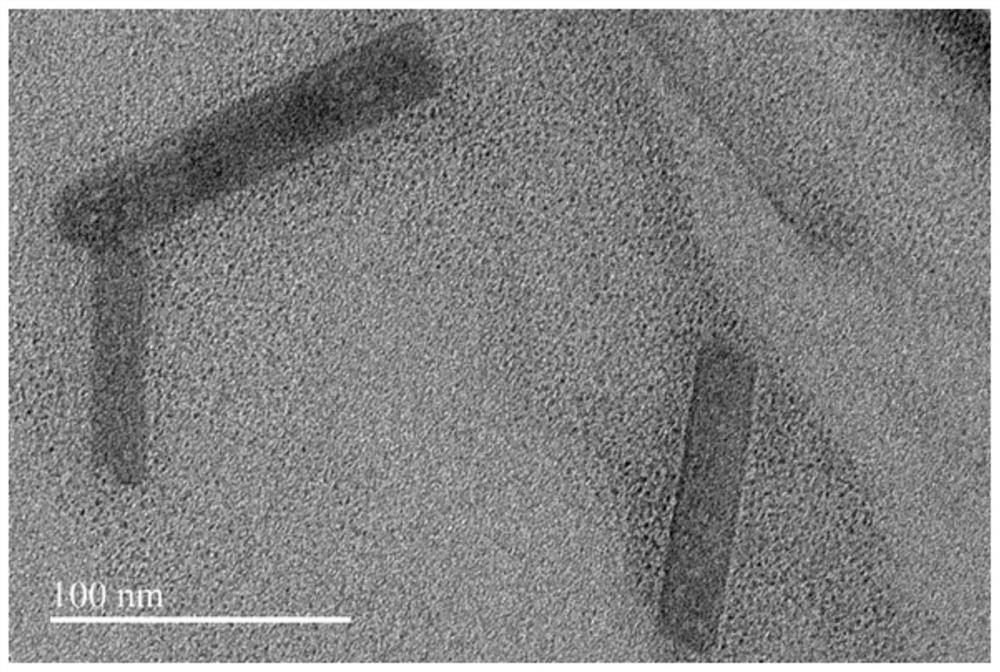

[0069] (2) The aqueous solution of nonanoic acid was not subjected to light ...

Embodiment 2

[0073] In this example, the hydrophilicity and hydrophobicity control of fluorescent vesicles and fluorescent micelles are realized by the following methods

[0074] (1) Mix linoleic acid with water, the stirring speed is 1000rpm, and the stirring time is 1min to obtain an aqueous solution of linoleic acid with a concentration of 140mM, and then carry out light pretreatment, the light wavelength is 800nm, and the light time is 12h. Reaction, stirring speed is 800rpm, stirring time 11h, after the completion of the reaction without any separation, then carry out vacuum distillation, the temperature is 60 ℃, time 3h, then add water and shake and stand for separation, the ratio of adding water to the product after distillation ( The volume ratio) is 4:1, the oscillation speed is 200rpm, the oscillation time is 6h, and the resting time is 20h, and hydrophilic fluorescent vesicles are obtained in the water intake system;

[0075] (2) The linoleic acid aqueous solution was not subjec...

Embodiment 3

[0078] In this example, the hydrophilicity and hydrophobicity control of fluorescent vesicles and fluorescent micelles are realized by the following methods

[0079] (1) Mix 2-oxooctanoic acid with water, the stirring speed is 100rpm, and the stirring time is 5min to obtain a 2-oxooctanoic acid aqueous solution with a concentration of 120mM, and then perform light pretreatment, the light wavelength is 300nm, and the light time is 5h , the reaction was carried out under stirring, the stirring speed was 500rpm, the stirring time was 5h, after the reaction was completed without any separation, then rotary steaming was carried out, the rotary steaming temperature was 50°C, the rotary steaming time was 2h, then water was added to vibrate and stand for separation, and water was added The ratio (volume ratio) to the product after rotary evaporation is 1:1, the oscillation speed is 100rpm, the oscillation time is 6h, and the standing time is 20h, and the water-taking system part is obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com