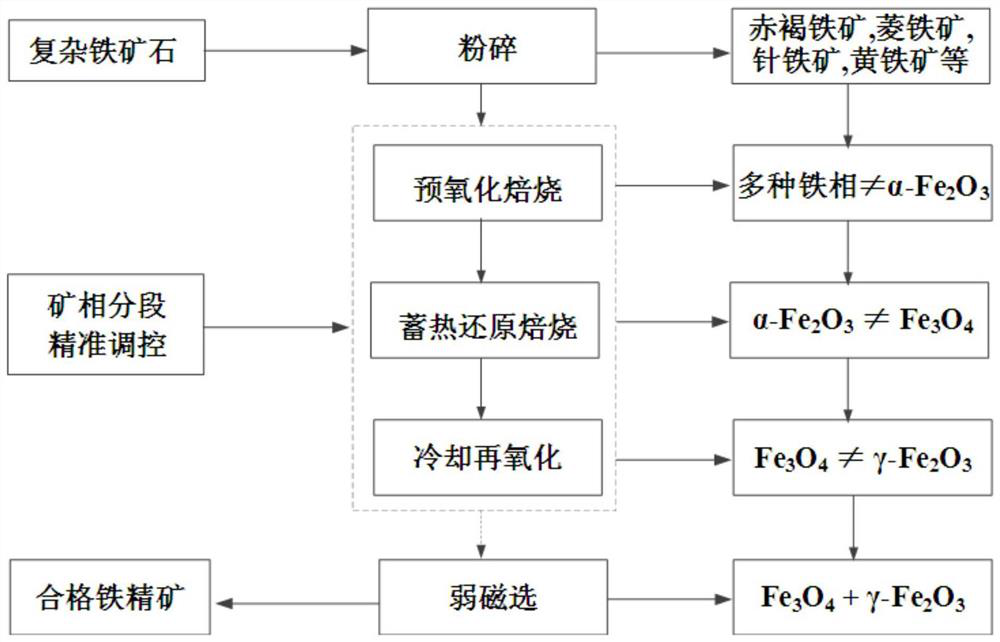

An enhanced separation method for complex iron ore based on precise regulation of ore phase segmentation

A complex technology for iron ore, applied in the field of enhanced separation of complex iron ore, to achieve the effects of easy control of product properties, reduced magnetic agglomeration, and reduced entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Complex iron ore has an iron grade of 35.20% and contains SiO by mass 2 43.11%;

[0056] Processes such as Figure 1 shown;

[0057] The complex iron ore is crushed by a crusher to a particle size of 2 to 15mm, and then the part of the mill is milled to a particle size of -0.074mm, accounting for 80% of the total mass, and the ore powder is obtained;

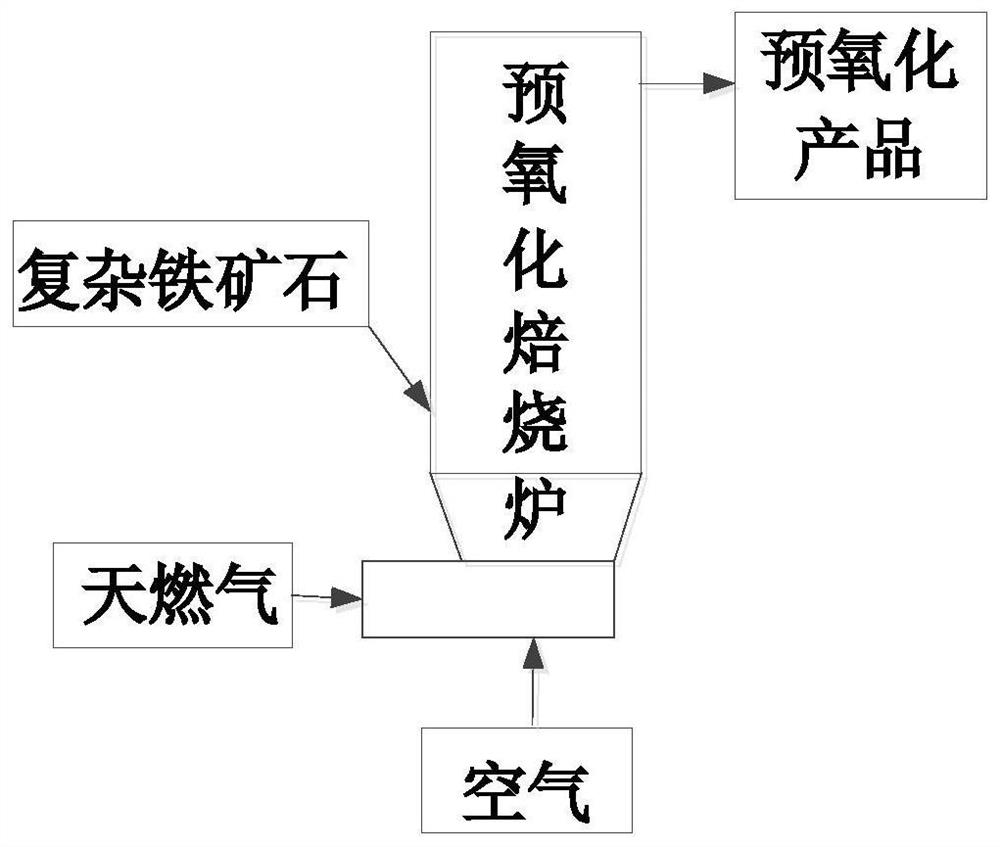

[0058]Adopt the pre-oxidation roaster with a burner and an air inlet at the bottom, the lower part of the pre-oxidation roaster is provided with an inlet, the upper part is connected with the cyclone separator through the material channel, and the exhaust port of the cyclone separator is connected with the induced draft through the pipe; the combustion flue gas is passed into the pre-oxidation roaster by the combustion of natural gas into the burner, and at the same time, under the condition of starting the induced draft, the air is introduced into the pre-oxidation roaster, and the ore powder is transported from the lower p...

Embodiment 2

[0064] Complex iron ore has an iron grade of 33.10% and contains SiO by mass 2 45.6%;

[0065] The method is the same as example 1, the difference is that:

[0066] (1) The part of the mill that is grinded to a particle size of -0.074mm accounts for 60% of the total mass;

[0067] (2) The pre-oxidation roasting temperature is 680 °C; the residence time of the solid materials in the pre-oxidation roasting furnace is 5min;

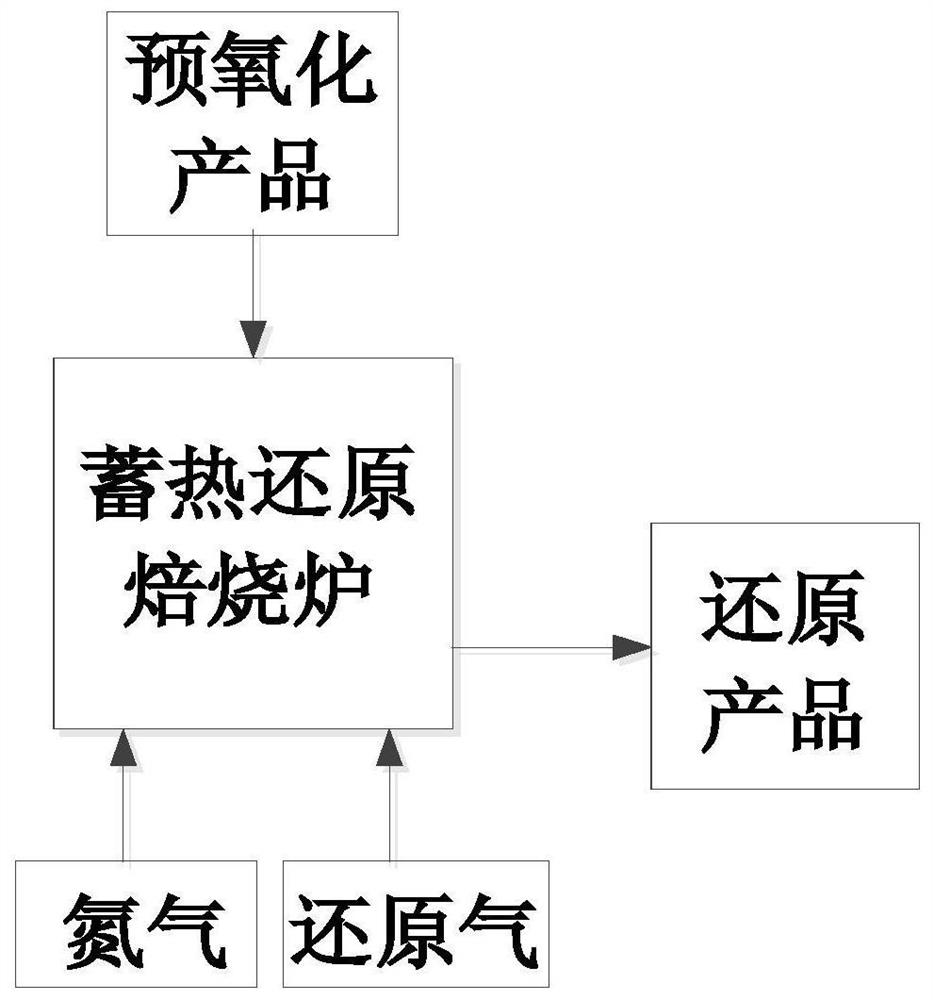

[0068] (3) The reduction roasting temperature is 550 °C and the reducing gas, and the amount of the reducing gas is based on the CO / H required for the complete reaction of the reducing roasting 2 The theoretical amount is 1:2 times; the volume flow ratio of nitrogen and reducing gas in the regenerative reduction roaster is 3:1; the residence time of the solid material in the regenerative reduction roasting furnace is 20min;

[0069] (4) The reduced material is cooled to 250 °C and discharged; the residence time of the reduced material in the primary cooling cycl...

Embodiment 3

[0073] Complex iron ore has an iron grade of 29.87% and contains SiO by mass 2 48.4%;

[0074] The method is the same as example 1, the difference is that:

[0075] (1) The part of the mill that is fine to a particle size of -0.074mm accounts for 50% of the total mass;

[0076] (2) The pre-oxidation roasting temperature is 700 °C; the residence time of the solid materials in the pre-oxidation roasting furnace is 2min;

[0077] (3) The reduction roasting temperature is 600 °C and the reducing gas, and the dosage of the reducing gas is based on the CO / H required for the complete reaction of the reduction roasting 2 The volume flow ratio of nitrogen and reducing gas in the regenerative reduction roaster is 1:1; the residence time of the solid material in the regenerative reduction roaster is 10min;

[0078] (4) The reduced material is cooled to 300 °C and discharged; the residence time of the reduced material in the primary cooling cyclone separator is 2min;

[0079] (5) The residenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com