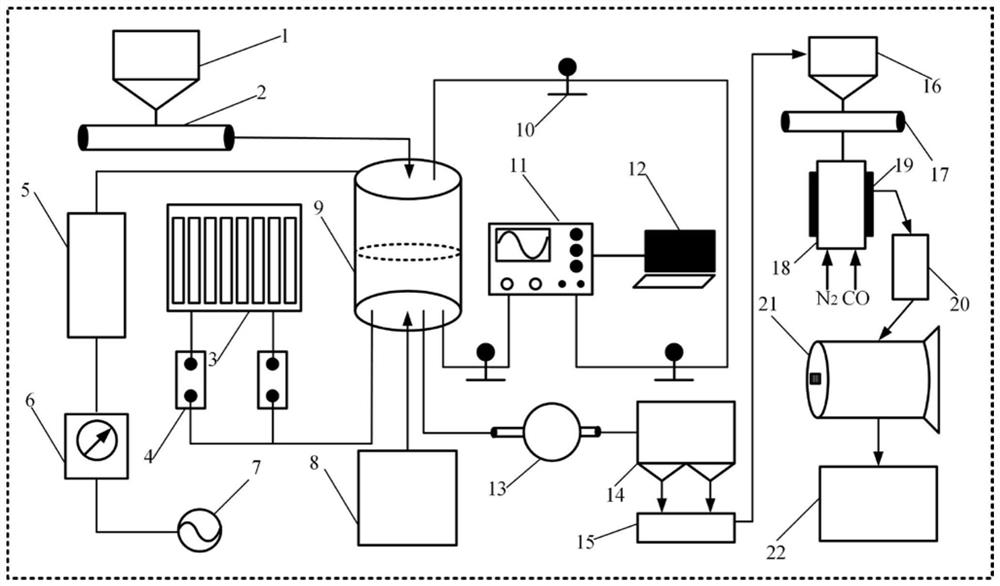

High-voltage electric pulse pretreatment-magnetizing roasting system and method for refractory iron ore

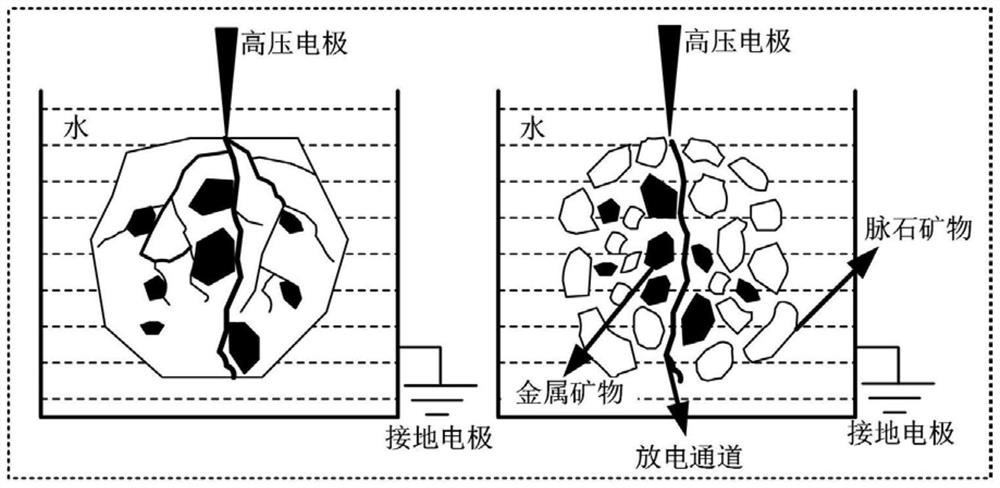

A high-voltage electric pulse and magnetization roasting technology, which is applied in the field of mineral processing, can solve the problems of large dust, over-grinding, and low degree of dissociation, and achieve the effect of strengthening the reaction rate, avoiding energy waste, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

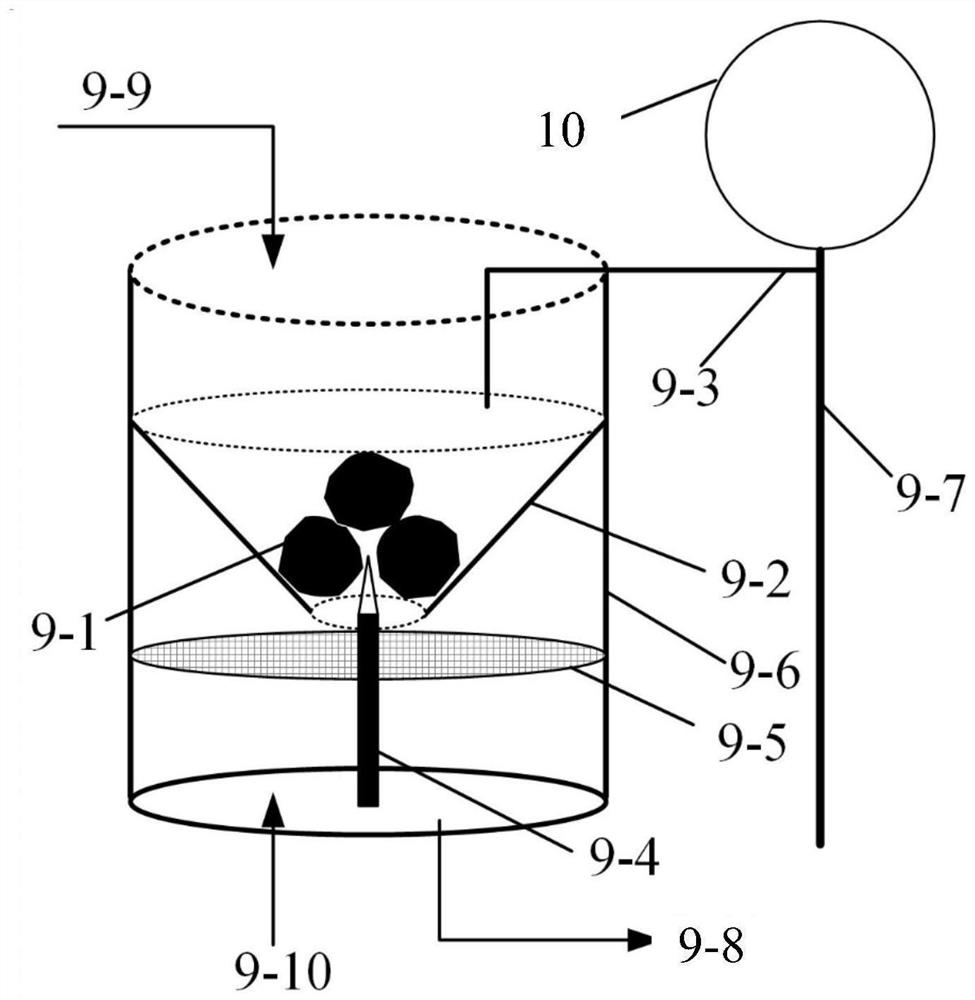

Method used

Image

Examples

Embodiment 1

[0039] In the embodiment of the present invention, the voltage of the input power supply is 220V, and the frequency is 50Hz.

[0040] The input voltage of the single-phase voltage regulator in the embodiment of the present invention is 0-250V, and the frequency is 50Hz.

[0041] The gas switch in the embodiment of the present invention is set according to the technology recorded in "Practical Technology of High Voltage Switchgear"; each gas switch includes two trigger balls; the material of the trigger ball is copper and the diameter is 20mm.

[0042] The Marx generator in the embodiment of the present invention is set according to the scheme recorded in "Pulse Power Technology and Application".

[0043] The model of the oscilloscope in the embodiment of the present invention is VC1100AN.

[0044] The voltage divider in the embodiment of the present invention is a hollow sphere with a diameter of 15 cm, and the material is stainless steel.

[0045] The material of the insula...

Embodiment 2

[0078] The structure of the refractory iron ore high-voltage electric pulse pretreatment-magnetization roasting system is the same as in Example 1;

[0079] Method is with embodiment 1, and difference is:

[0080] (1) The pulse voltage is 120kV, the pulse frequency is 20Hz, and the residence time of the ore in the high-voltage electric pulse crushing cavity is 50min;

[0081] (2) The pretreated ore is in a suspended state under the action of airflow and heated to 550°C; the volume flow ratio of nitrogen and carbon monoxide fed into the suspension reduction roaster is 3.5; the residence time of the pretreated ore in the suspension reduction roaster The time is 25 minutes;

[0082] (3) The cooling material temperature is 65°C;

[0083] (4) Add water to the cooling material to make an ore slurry with a mass concentration of 80%, and then grind the ore through a ball mill until the particle size of the solid material ≤ 0.074mm accounts for 80% of the total mass; the ground mater...

Embodiment 3

[0088] The structure of the refractory iron ore high-voltage electric pulse pretreatment-magnetization roasting system is the same as in Example 1;

[0089] Method is with embodiment 1, and difference is:

[0090] (1) The pulse voltage is 80kV, the pulse frequency is 50Hz, and the residence time of the ore in the high-voltage electric pulse crushing chamber is 80min;

[0091] (2) The pretreated ore is in a suspended state under the action of the airflow and is heated to 500°C; the volume flow ratio of nitrogen and carbon monoxide fed into the suspension reduction roaster is 4; the residence time of the pretreated ore in the suspension reduction roaster The time is 30 minutes;

[0092] (3) The cooling material temperature is 60°C;

[0093] (4) Add water to the cooling material to make a slurry with a mass concentration of 60%, and then grind it through a ball mill until the particle size of the solid material ≤ 0.074mm accounts for 85% of the total mass; use a weak magnetic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com