Suspension roasting system for heating, cracking and strengthening reduction of iron-containing material

A technology of suspension roasting and suspension roasting furnace, which is applied in grain processing and other fields, and can solve the problems of high energy consumption and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

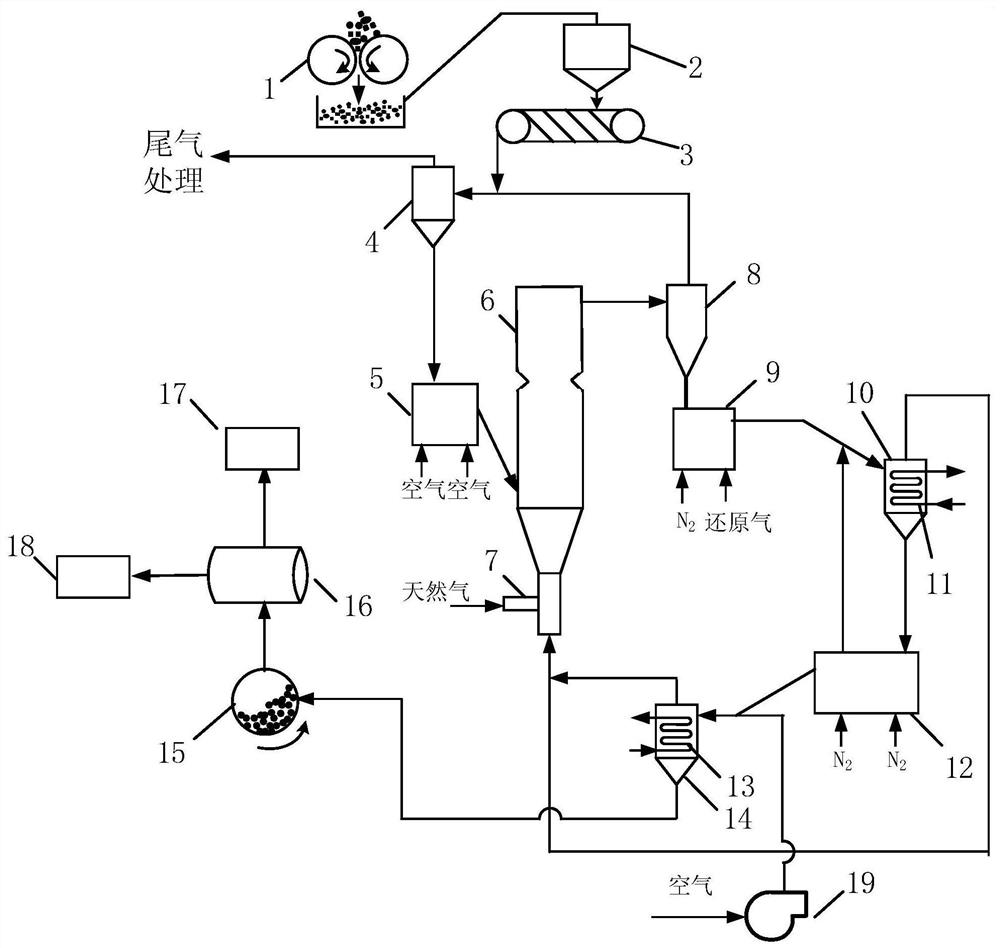

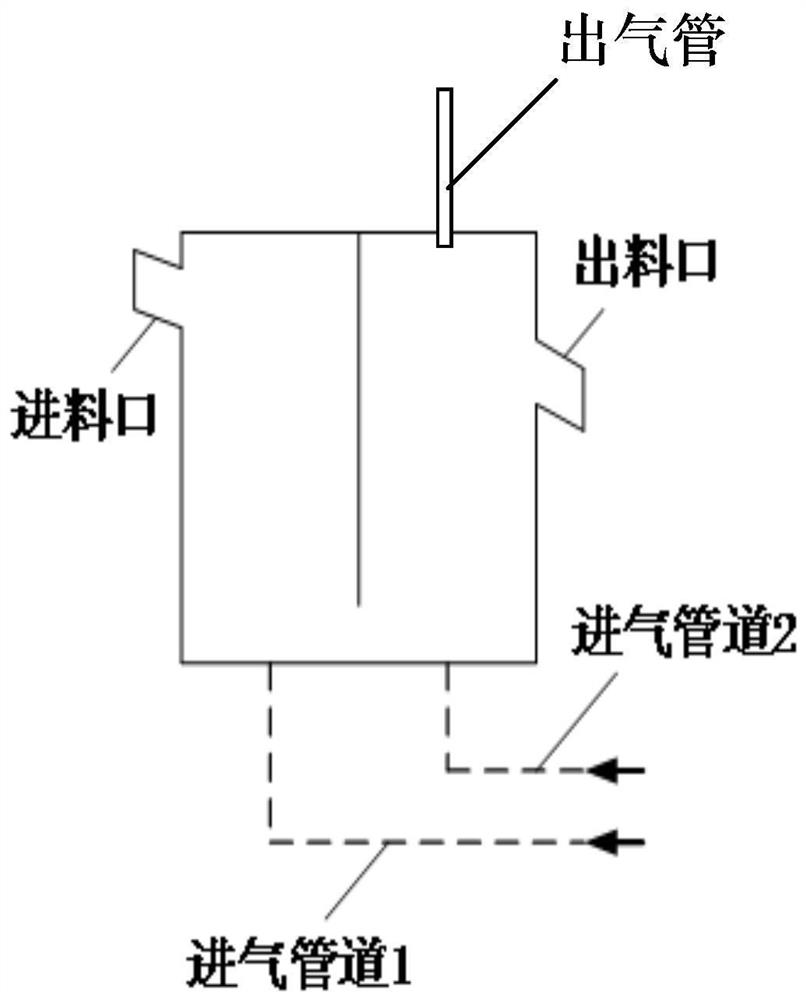

[0067] The structure of the suspension roasting system for heating and cracking to strengthen the reduction of iron-containing materials is as follows: figure 1 As shown, it includes a high-pressure roller mill 1, a feeding bin 2, a first cyclone separator 4, a first flow sealing valve 5, a pre-oxidation suspension roaster 6, a second cyclone separator 8, a regenerative reduction roaster 9, Nitrogen cooling cyclone separator 10, second flow sealing valve 12, air cooling cyclone separator 14, ball mill 15 and magnetic separator 16;

[0068] The outlet of the storage tank below the high-pressure roller mill 1 is opposite to the inlet of the feed bin 2, and the outlet of the feed bin 2 matches the feed inlet of the first cyclone separator 4; the outlet of the first cyclone separator 4 The discharge port is communicated with the feed port of the first flow seal valve 5, and the discharge port of the first flow seal valve 5 is communicated with the feed port of the pre-oxidation su...

Embodiment 2

[0088] System structure is the same as embodiment 1;

[0089] The miscellaneous iron ore iron grade used is TFe 37.9%, containing SiO by mass percentage 2 32.3%; Method method is the same as embodiment 1, and difference is:

[0090] (1) Particle size -0.074mm in the mineral powder accounts for 30-55% of the total mass;

[0091] (2) The pre-oxidation roasting temperature is 810°C; the residence time of the solid material in the pre-oxidation roaster 6 is 7min;

[0092] (3) The reduction roasting temperature is 520°C; the amount of reducing gas is based on the CO / H required for the complete reaction of the reduction roasting 2 1:1 times of the theoretical amount; the volume flow ratio of nitrogen and reducing gas in the regenerative reduction roaster 9 is 5:1; the residence time of the solid material in the regenerative reduction roaster 9 is 55min;

[0093] (4) The temperature drops to 210° C. to form a cooling reduction material; the residence time of the reduction materia...

Embodiment 3

[0096] System structure is the same as embodiment 1;

[0097] The iron grade of the complex iron ore used is TFe 32.1%, containing SiO by mass percentage 2 33.8%; Method method is the same as embodiment 1, and difference is:

[0098] (1) Particle size -0.074mm in the mineral powder accounts for 30-55% of the total mass;

[0099] (2) The pre-oxidation roasting temperature is 830° C.; the residence time of the solid material in the pre-oxidation roaster 6 is 5 min;

[0100] (3) The reduction roasting temperature is 550°C; the amount of reducing gas is based on the CO / H required for the complete reaction of the reduction roasting 2 1.3 times the theoretical amount; the volume flow ratio of nitrogen and reducing gas in the regenerative reduction roaster 9 is 1:1; the residence time of the solid material in the regenerative reduction roaster 9 is 40 minutes;

[0101] (4) The temperature drops to 230° C. to form a cooling reduction material; the residence time of the reduction m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com