Multi-arm star-type polymer and preparation method thereof

A technology of polymers and multi-armed stars, applied in the field of multi-armed star polymers and its preparation, can solve the problems of low molecular weight of multi-armed star polymers, difficulty in adjusting and controlling the structure and size of the core, and achieve The effects of easy polymerization, convenient modification, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

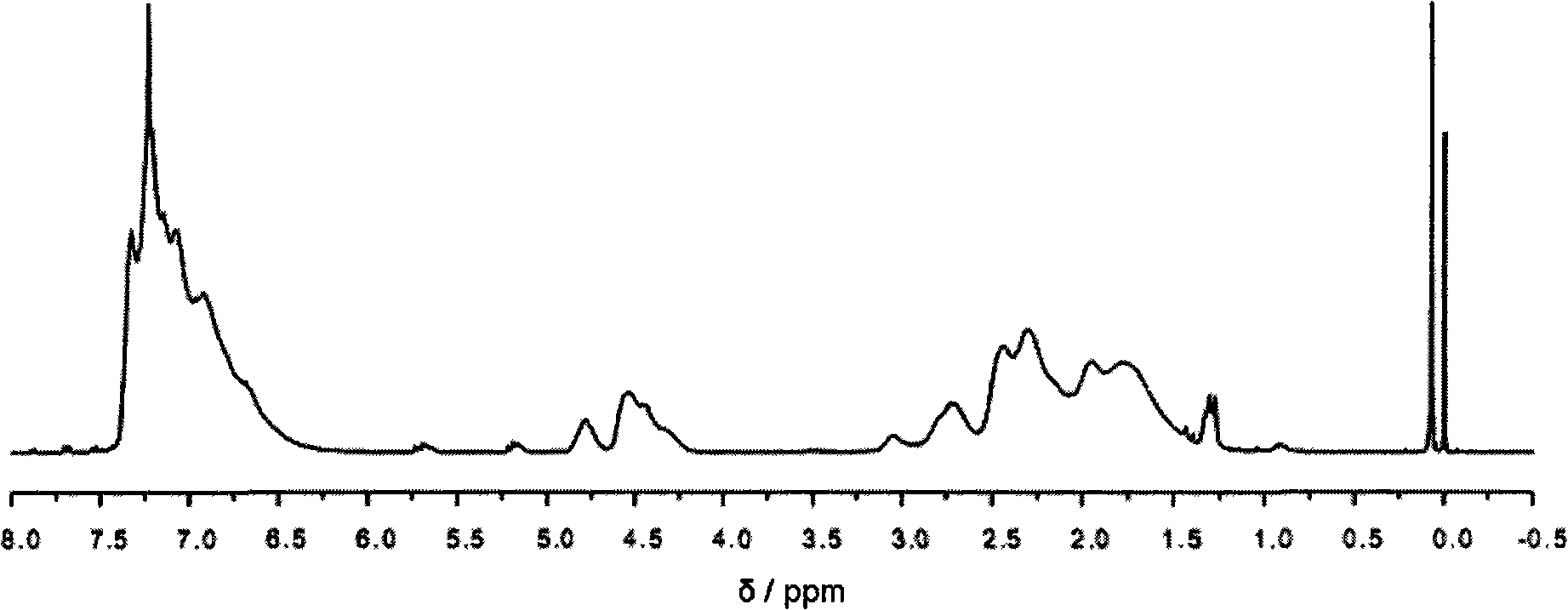

[0023] 1) Preparation of the core of the star-shaped multi-arm polymer

[0024] Add 0.659g of 2,2-bipyridine and 0.209g of cuprous chloride into a 100ml two-necked bottle, repeatedly vacuumize and fill with argon. Then 8ml of chlorobenzene, 3g of p-chloromethylstyrene and 2.42g of styrene were added in sequence. Under the protection of argon, react at 120°C for 4 hours. The reaction was quenched by the addition of tetrahydrofuran, and the product mixture was stirred for 2 hours, then chromatographed on neutral alumina. The solution obtained by chromatography was rotatively distilled and then precipitated with ethanol / water mixed solution with a volume ratio of 5:1. The obtained white precipitate was dried in vacuum for 24 hours and then stored in an inert atmosphere. The resulting chlorine-containing hyperbranched polystyrene copolymer totaled 5.15 g, and the yield was 95%. The measured number average molecular weight was 16270, and the molecular weight distribution was 3.4...

Embodiment 2

[0028] Add 0.2 g of the chlorine-containing hyperbranched polystyrene macromolecular initiator prepared in step 1) of Example 1, and 0.0416 g of cuprous chloride into a 100 ml three-necked flask, repeatedly vacuumize and fill with argon. Then 15ml of pyridine, 2.29g of acrylonitrile, and 0.1456g of pentamethyldiethylenetriamine were added in sequence. Under the protection of argon, react at 130°C for 4 hours. Then 15 ml of xylene was added dropwise. The reaction was continued until the 10th hour, when tetrahydrofuran was added to terminate the reaction, and the product mixture was stirred for 2 hours, then chromatographed on neutral alumina. The solution obtained by chromatography was rotatively distilled and then precipitated with ethanol / water mixed solution with a volume ratio of 5:1. The obtained white precipitate was dried in vacuum for 24 hours and then stored in an inert atmosphere. The obtained chlorine-containing star polymer was 1.87 g in total, and the yield was 6...

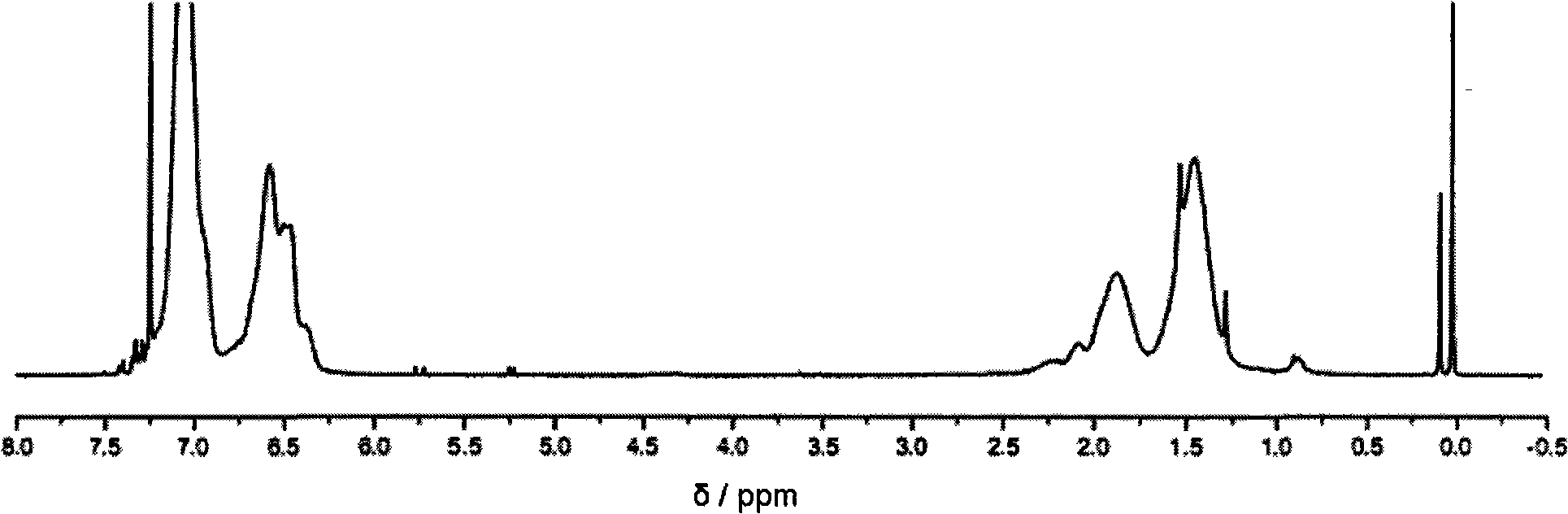

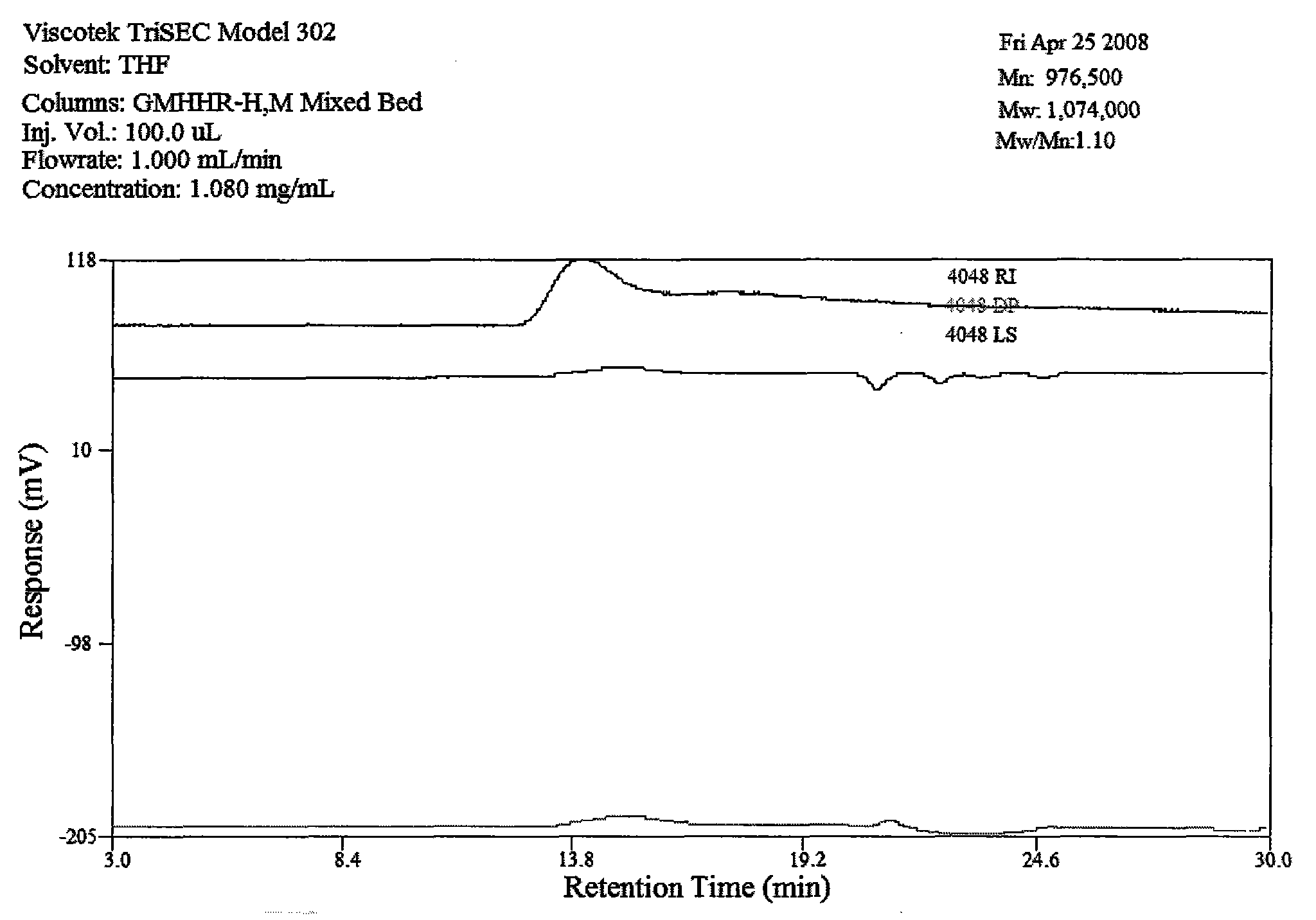

Embodiment 3

[0030] In a 100ml three-necked flask, add 0.2g of the chlorine-containing hyperbranched polystyrene type macromolecular initiator prepared in step 1) of Example 1, 0.1318g2, 2'-bipyridyl, 0.0416g cuprous chloride, and repeatedly vacuumize And filled with argon. Then 15ml of chlorobenzene and 4.5g of methyl methacrylate were added successively. Under the protection of argon, react at 100°C for 4 hours. Then 15 ml of 1,4-dioxane was added dropwise. Continue the reaction until the 10th hour, add tetrahydrofuran to terminate the reaction, stir the product mixture for 2 hours, and then precipitate it with a mixed solution of ethanol / water with a volume ratio of 5:1. The obtained white precipitate is dried in vacuum for 24 hours and stored in an inert atmosphere . The obtained chlorine-containing star polymer was 3.68 g in total, and the yield was 78.3%. The measured number average molecular weight was 1,007,000, and the molecular weight distribution was 2.74.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com