Ore high-voltage pulse discharge pretreatment system and using method thereof

A high-voltage pulse discharge and high-voltage electric pulse technology, which is applied in the field of mineral processing, can solve the problems of large dust, low degree of fragmentation and dissociation, and excessive pulverization, so as to improve the degree of dissociation, improve the grinding efficiency, and avoid the waste of energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

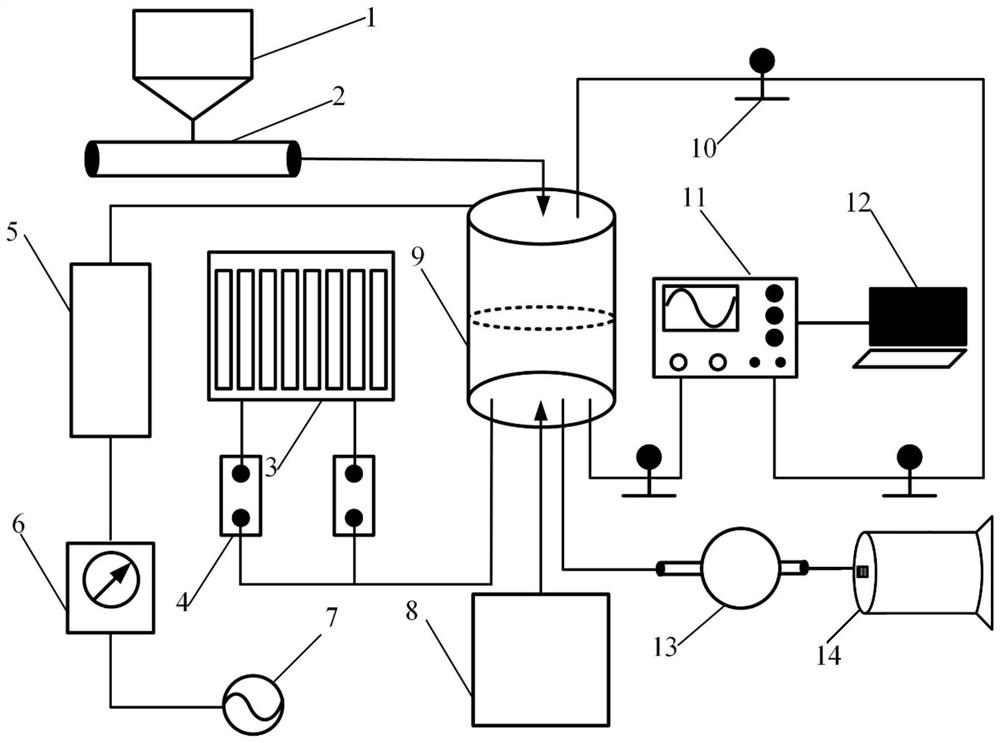

[0054] The structure of ore high-voltage pulse discharge pretreatment system is as follows: figure 1 As shown, it includes feeding bin 1, screw feeder 2, high-voltage electric pulse crushing chamber 9, pulse high-voltage electric generator 3, output power supply 5, insulating liquid storage pool 8 and oscilloscope 11; high-voltage electric pulse crushing chamber 9 structures such as figure 2 shown;

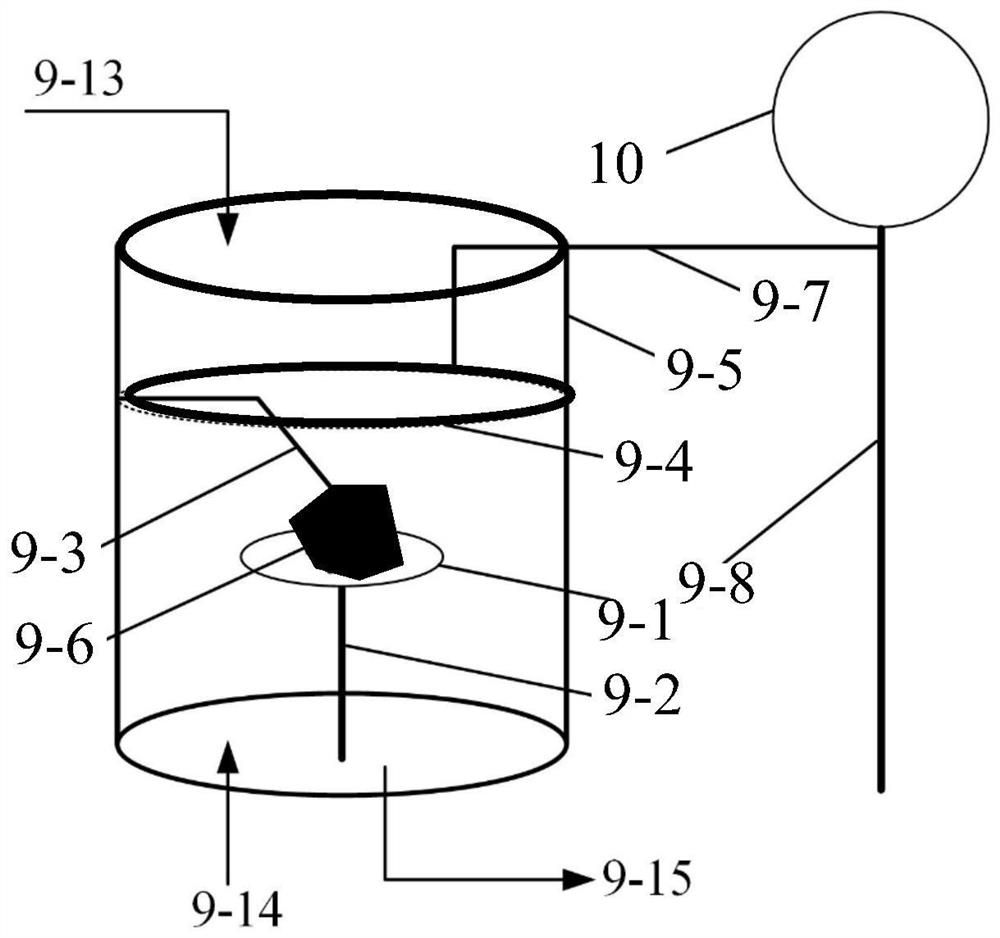

[0055] The discharge port of the feeding bin 1 is matched with the feed end of the screw feeder 2, and the discharge end of the screw feeder 2 is matched with the feed port of the high-voltage electric pulse crushing chamber 9; the high-voltage electric pulse crushing The top of the cavity 9 is provided with a feed port 9-13, and the bottom is provided with a liquid inlet 9-14 and a discharge port 9-15;

[0056] The interior of the high-voltage electric pulse crushing chamber 9 is provided with a positive pole and a negative pole. The positive pole is connected in parallel with...

Embodiment 2

[0075] The ore high-voltage pulse discharge pretreatment system structure is the same as that of embodiment 1;

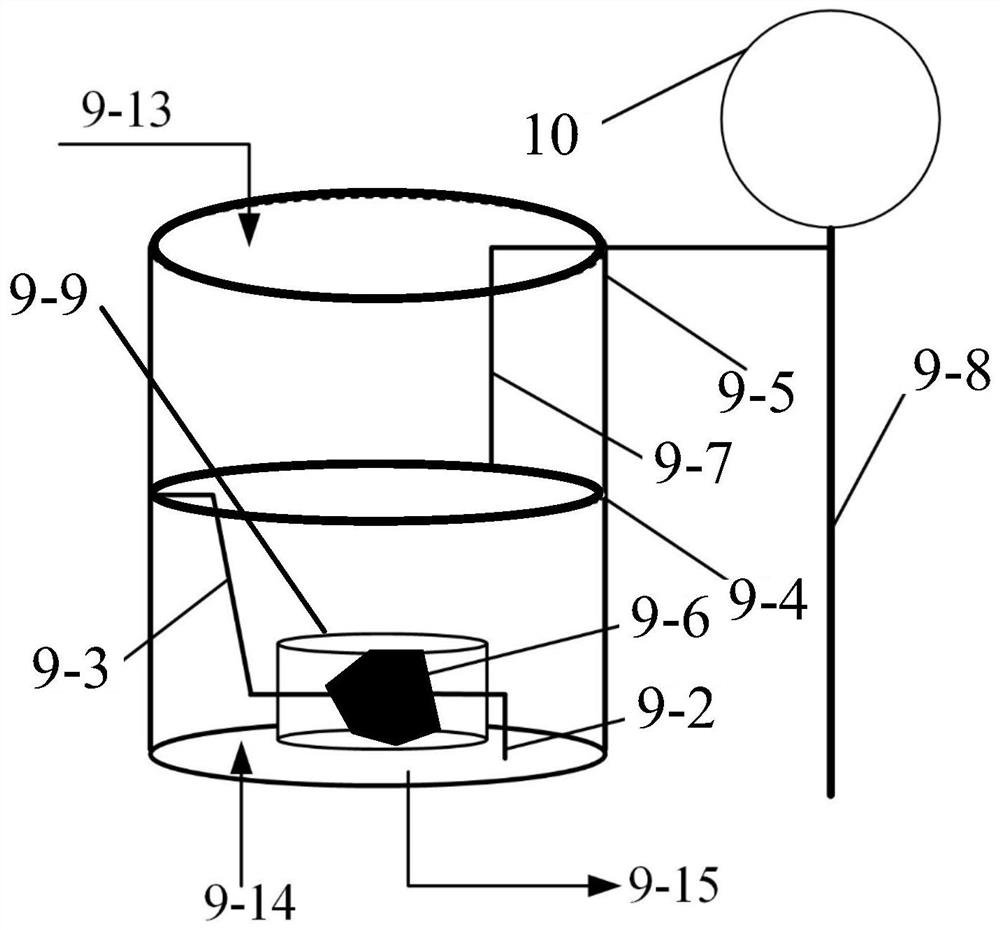

[0076] The structure of the high-voltage electric pulse crushing cavity 9 is as follows: image 3 As shown, it includes an insulating cylinder 9-5 and its internal trough 9-9; the top plate connected to the top of the insulating cylinder 9-5 is provided with a feed inlet 9-13, and the bottom plate of the insulating cylinder 9-5 is provided with a liquid inlet Port 9-14 and discharge port 9-15; the positive pole and negative pole are high-voltage positive pole 9-2 and high-voltage negative pole 9-3 respectively, and the front ends of high-voltage positive pole 9-2 and high-voltage negative pole 9-3 are located inside the material tank 9-9; The high-voltage positive pole 9-2 is connected in parallel with two gas switches 4 through a wire, and the high-voltage negative pole 9-3 is connected with the output power supply 5 through a wire; the space between the high-volta...

Embodiment 3

[0085] The ore high-voltage pulse discharge pretreatment system structure is the same as that of embodiment 1;

[0086] The structure of the high-voltage electric pulse crushing cavity 9 is as follows: Figure 4 As shown, it includes an insulating cylinder 9-5 and its internal screen 9-10; the top plate connected to the top of the insulating cylinder 9-5 is provided with a feed inlet 9-13, and the bottom plate of the insulating cylinder 9-5 is provided with a liquid inlet Port 9-14 and discharge port 9-15; Rod-shaped high-voltage positive pole 9-11 is used as the positive pole and passes through the screen mesh 9-10 placed horizontally; the bottom end of rod-shaped high-voltage positive pole 9-11 is connected in parallel with two gas switches 4 through wires , the top of the rod-shaped high-voltage positive electrode 9-11 is located above the screen 9-10; the funnel-shaped high-voltage negative electrode 9-12 is used as the negative electrode, and its internal space is an inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com