Colloid ozone bubble as well as preparation method and application thereof

A technology of ozone and colloid, applied in chemical instruments and methods, oxidized water/sewage treatment, adsorbed water/sewage treatment, etc., can solve problems such as inability to achieve environmental restoration, and achieve easy promotion, huge application value, and high utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

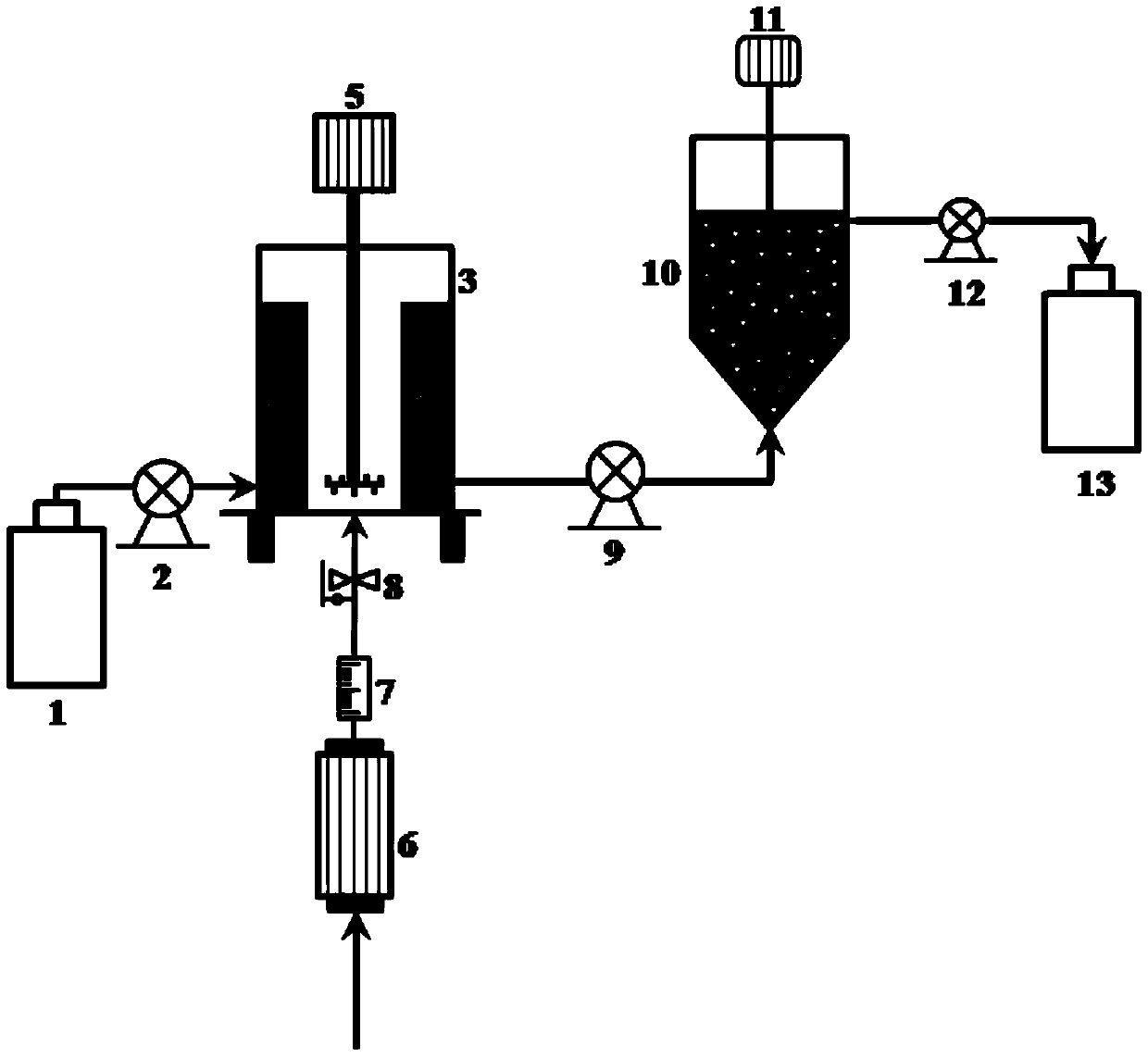

Method used

Image

Examples

Embodiment 1

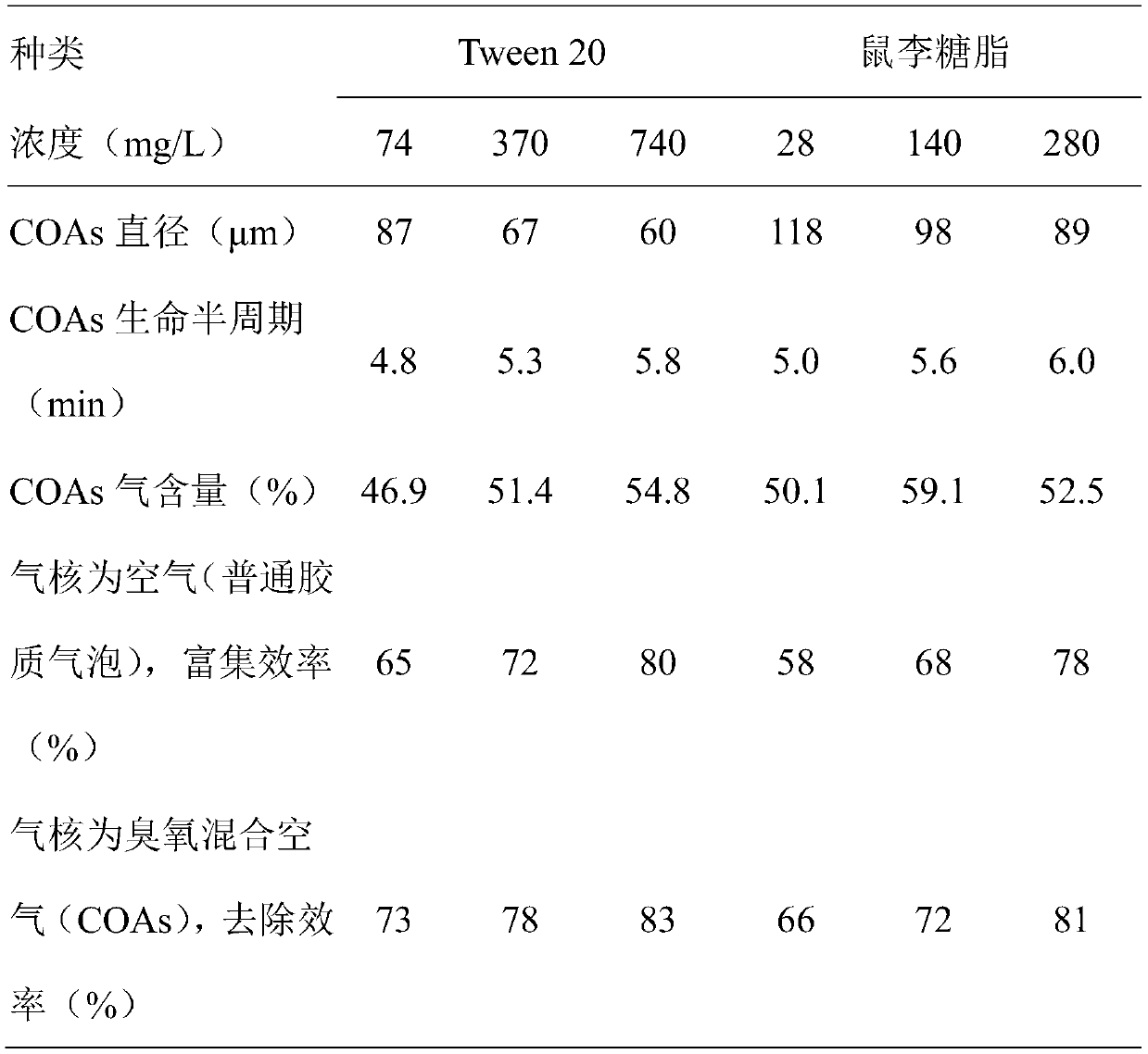

[0031] Effects of Nonionic Surfactant Concentration on COAs Properties and PAHs Removal Efficiency

[0032]The high-pressure electrolysis method is adopted, and the air gas flow rate is 16.7mL / min to prepare ozone, and the yield is 10g / h. Tween20 solution with a concentration of 74mg / L (about 1 times the critical micelle concentration), 370mg / L (about 5 times the critical micelle concentration) and 740mg / L (about 10 times the critical micelle concentration), 28mg / L ( About 1 times the critical micelle concentration), 140mg / L (about 5 times the critical micelle concentration) and 280mg / L (about 10 times the critical micelle concentration) rhamnolipid solutions were used as bubble generating solutions. Preset 1L of surfactant solution in the bubble generation tank and stir it with a high-speed stirrer at 5000rpm. At the same time, the surfactant solution is passed into the tank from the bottom of the side wall of the bubble generation tank at a flow rate of 60mL / min. Freshly pre...

Embodiment 2

[0039] Influence of Ozone Introductory Rate on COAs Properties and PAHs Removal Efficiency During COAs Preparation

[0040] Ozone was prepared by high-pressure electrolysis, the air flow rate was 16.7mL / min, and a generator with an ozone yield of 10g / h was selected. Tween20 solution with a concentration of 74 mg / L (about 1 time of critical micelle concentration) and rhamnolipid solution of 28 mg / L (about 1 time of critical micelle concentration) were used as bubble generating liquid. Preset 1L of surfactant solution in the bubble generation tank and stir it with a high-speed stirrer at 5000rpm. At the same time, the surfactant solution is passed into the tank from the bottom of the side wall of the bubble generation tank at a flow rate of 60mL / min. Freshly prepared ozone mixed with air From the central position of the bottom of the bubble generation tank, it was introduced into the tank at the speed of 16.7mL / min, 33.3mL / min, and 66.7mL / min respectively, and the bubble generat...

Embodiment 3

[0046] Effects of different concentrations of PAHs in sediments on the properties of COAs and the removal efficiency of PAHs

[0047] A high-pressure electrolysis method is adopted with an air flow rate of 66.7mL / min to prepare ozone, and a generator with an ozone yield of 10g / h is selected. Tween20 solution with a concentration of 74 mg / L (about 1 time of critical micelle concentration) and rhamnolipid solution of 28 mg / L (about 1 time of critical micelle concentration) were used as bubble generating liquid. Preset 1L of surfactant solution in the bubble generation tank and stir it with a high-speed stirrer at 5000rpm. At the same time, the surfactant solution is passed into the tank from the bottom of the side wall of the bubble generation tank at a flow rate of 60mL / min. Freshly prepared ozone mixed with air From the central position of the bottom of the bubble generation tank, it was passed into the tank at a rate of 66.7mL / min, and the bubble generation time was 60s to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com