Stone coal vanadium ore oxidizing, crystal breaking, roasting and vanadium extracting comprehensive utilization system

A kind of stone coal vanadium and crystal breaking technology, applied in the fields of silicon oxide, silicon dioxide, chemical industry, etc., can solve the problems of low processing capacity, high operating cost, environmental pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

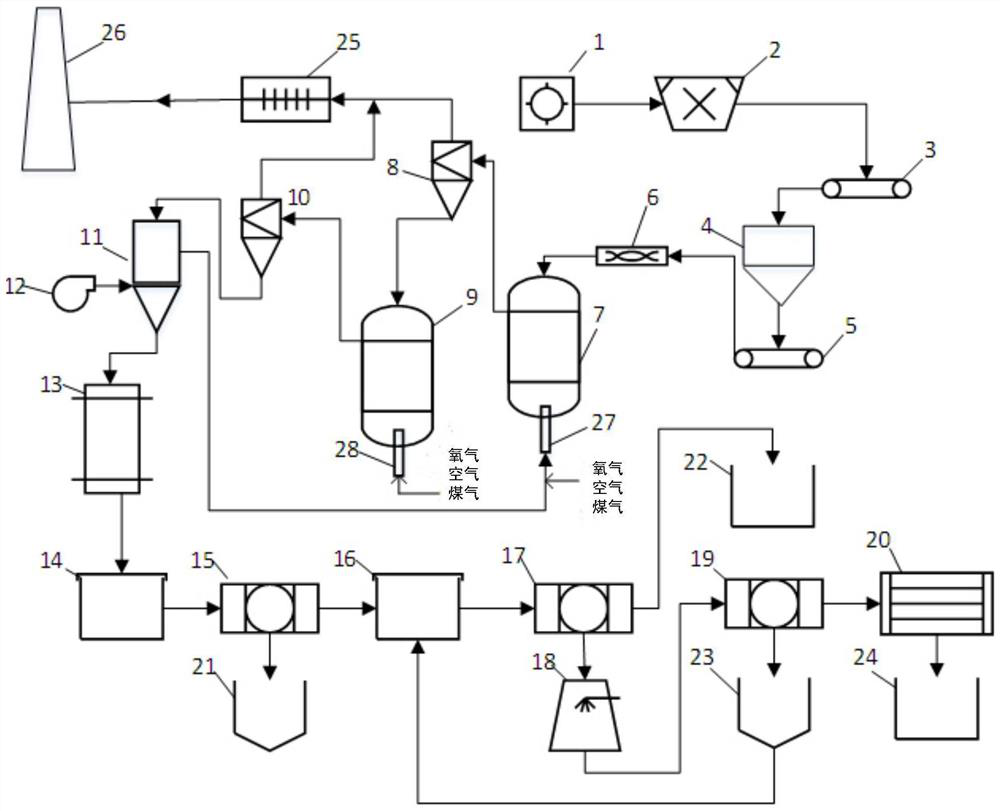

[0067] The structure of the comprehensive utilization system for vanadium extraction by oxidative breaking crystal roasting of stone coal vanadium ore is as follows: figure 1 As shown, it includes a crusher 1, a high-pressure roller mill 2, a feed bin 4, a screw feeder 6, a suspension decarburization roaster 7, a first cyclone separator 8, a suspension crystal breaking roaster 9, and a second cyclone separation Device 10, cooler 11, acid-mixed aging furnace 13, first leaching tank 14, first filtering device 15, second leaching tank 16, second filtering device 17, pH value adjustment tank 18, third filtering device 19, drying Device 20, dust removal device 25, chimney 26, first burner 27, second burner 28;

[0068] The discharge port of the crusher 1 is opposite to the feed port of the high pressure roller mill 2, the discharge port of the high pressure roller mill 2 is opposite to the first feeding belt 3, and the discharge end of the first feeding belt 3 is connected to the f...

Embodiment 2

[0086] The system structure of the comprehensive utilization of vanadium extraction by oxidizing, cracking, crystal-breaking, roasting and roasting of stone coal vanadium ore is the same as in embodiment 1;

[0087] The stone coal vanadium ore used contains SiO by mass percentage 2 61.01%, Al 2 o 3 7.81%, V 2 o 5 0.79%, TFe2.76%, CaO 2.91%, MgO 1.33%, Na 2 O 1.33%, C 12.39%;

[0088] Method is with embodiment 1, and difference is:

[0089] (1) The part that is ground to a particle size of ≤0.074mm accounts for 66% of the total mass;

[0090] (2) The decarburization reaction is carried out at 800°C, and the residence time of fine ore in the suspension decarburization roaster is 40 minutes; the volume flow ratio of oxygen and air is 1:2;

[0091] (3) The crystal breaking oxidation reaction is carried out at 850°C, and the residence time of the decarburized material in the suspended crystal breaking roaster is 90 minutes; the volume flow ratio of oxygen and air is 1:5; ...

Embodiment 3

[0098] The system structure of the comprehensive utilization of vanadium extraction by oxidizing, cracking, crystal-breaking, roasting and roasting of stone coal vanadium ore is the same as in embodiment 1;

[0099] The stone coal vanadium ore used contains SiO by mass percentage 2 60.32%, Al 2 o 3 7.14%, V 2 o 5 0.93%, TFe2.17%, CaO 3.45%, MgO 1.69%, Na 2 O 1.18%, C 10.56%;

[0100] Method is with embodiment 1, and difference is:

[0101] (1) The part that is ground to a particle size of ≤0.074mm accounts for 70% of the total mass;

[0102] (2) The decarburization reaction is carried out at 850°C, and the residence time of fine ore in the suspension decarburization roaster is 30 minutes; the volume flow ratio of oxygen and air is 1:3;

[0103] (3) The crystal breaking oxidation reaction is carried out at 900°C, and the residence time of the decarburized material in the suspended crystal breaking roaster is 60 minutes; the volume flow ratio of oxygen and air is 1:8; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com