Low-resistance efficient column tray

A low-resistance and high-efficiency technology, applied in the fields of dust washing equipment, gas-liquid heat transfer, and mass transfer, it can solve the problems of large resistance and large gas energy loss, and achieve the effect of large operation elasticity, low gas flow resistance and no amplification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

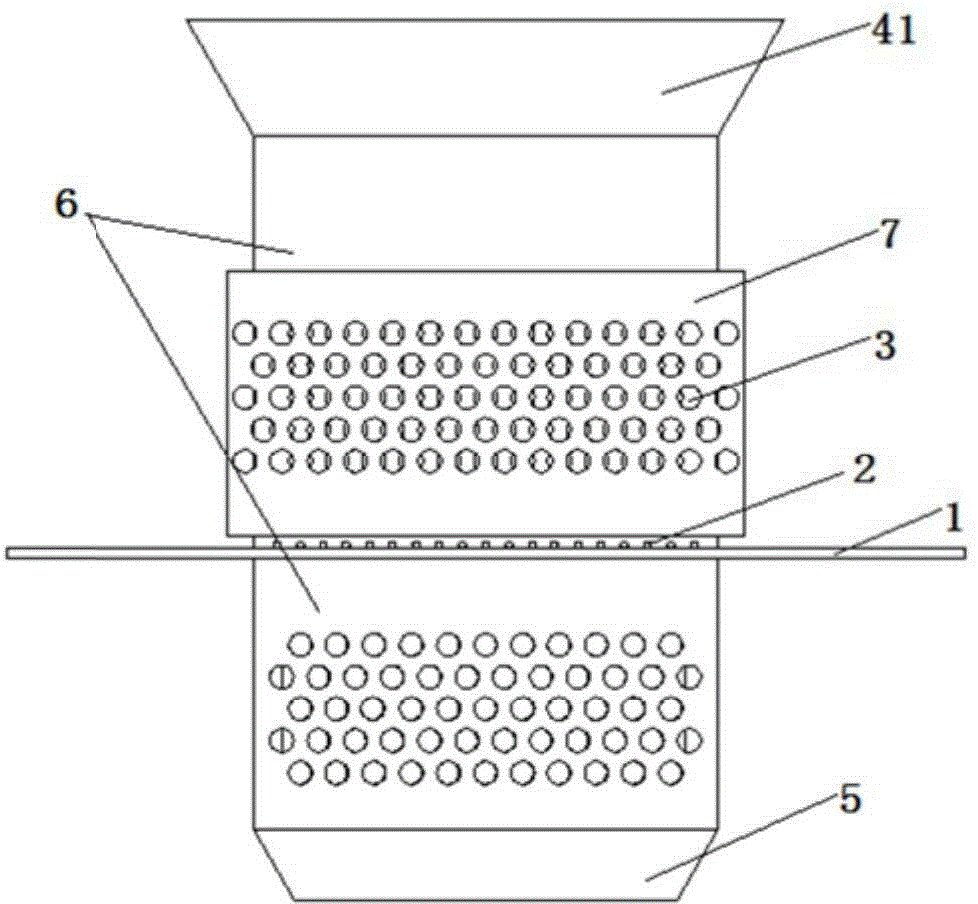

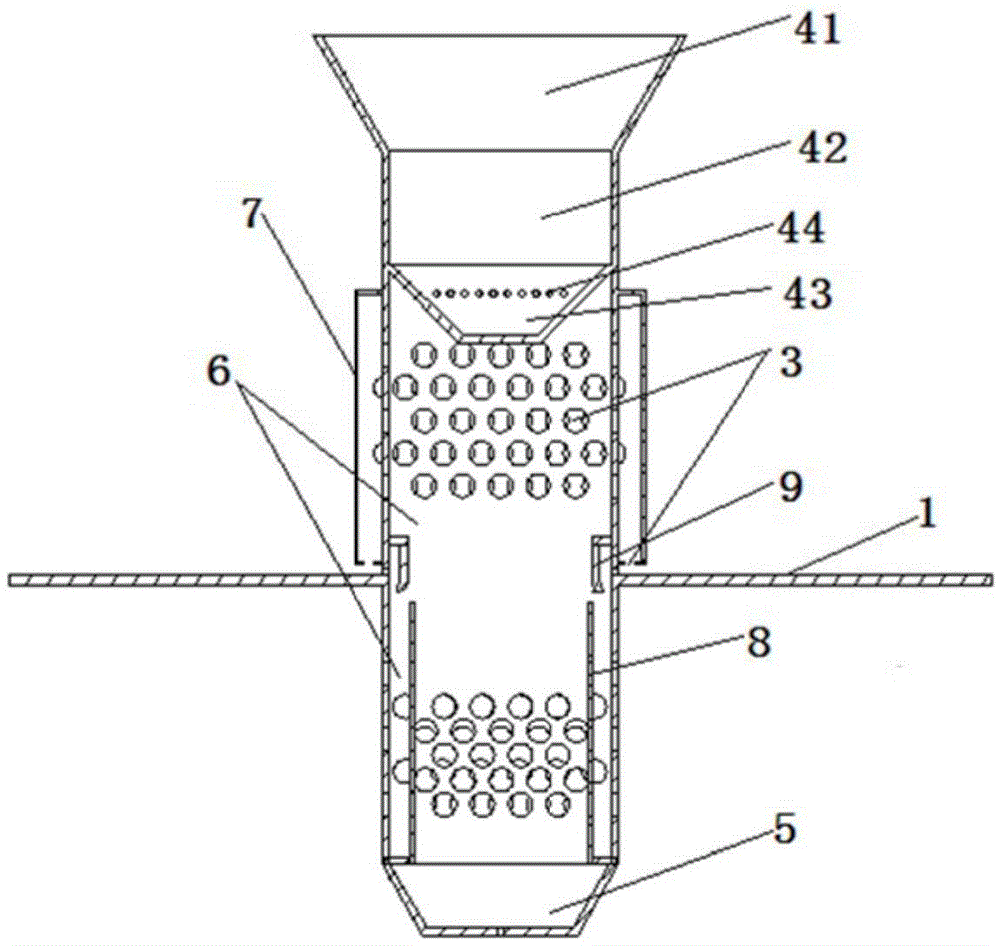

[0043] Such as Figure 1-7 A low-resistance high-efficiency tray is shown, including a tray 1 and a number of caps 6 that pass through the tray 1 and are welded to the tray 1 (and the caps 6 protrude upward or downward from the plane of the tray 1 by 100mm-250mm , the specific height is designed according to the actual height of the tower body), the top of the cap 6 is provided with a sump 4, the bottom is provided with a downcomer structure 5, the part of the cap positioned at the upper end of the tray 1 and the part of the cap positioned at the lower end of the tray 1 There are several rows of sieve holes 3 staggered in the middle of the tray, and an outer liquid-retaining sieve plate 7 concentric with it is arranged on the periphery of the upper cap at the upper end of the tray, and the outer liquid-retaining sieve plate 7 is welded to the side wall of the cap. cavity structure, and the bottom of the cavity structure is provided with a number of sieve holes 3, which are use...

Embodiment 2

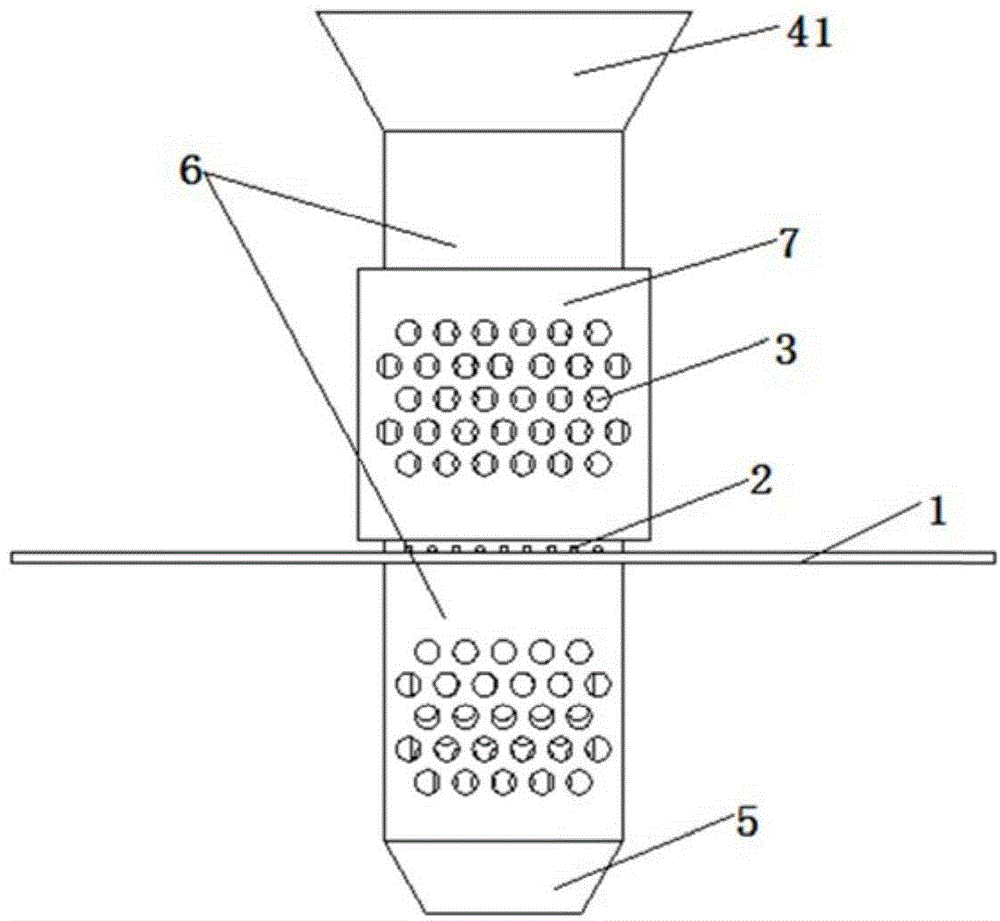

[0049] Such as Figure 9 and 10 As shown, the present invention provides a low-resistance high-efficiency tray, comprising a tray 1 and a cap 6 (the cap 6 is a cylindrical structure with openings at both ends), the top of the cap 6 is provided with a sump 4, and the bottom A downcomer structure 5 is provided, and several rows of sieve holes 3 are distributed in parallel in the middle part of the part of the cap located at the upper end of the tray 1 and the part of the cap located at the lower end of the tray 1. The outer liquid-retaining sieve 7 concentric with it (and the outer liquid-retaining sieve protrudes about 5-150 mm from the side wall of the cap), and the outer liquid-retaining sieve 7 and the side wall of the cap are welded into a cavity structure , the bottom of the cavity structure is provided with several sieve holes 3, and the side wall of the outer liquid retaining sieve plate 7 is also provided with several rows of sieve holes 3 in parallel; On the side wal...

Embodiment 3

[0055] Such as Figure 11 As shown, the present invention provides a low-resistance high-efficiency tray, comprising a tray 1 and a cap 6 (the cap 6 is a cylindrical structure with openings at both ends), the top of the cap 6 is provided with a sump 4, and the bottom A downcomer structure 5 is provided, and several rows of sieve holes 3 are distributed in parallel in the middle part of the part of the cap located at the upper end of the tray 1 and the part of the cap located at the lower end of the tray 1. The outer liquid-retaining sieve 7 concentric with it (and the outer liquid-retaining sieve protrudes about 5-150 mm from the side wall of the cap), and the outer liquid-retaining sieve 7 and the side wall of the cap are welded into a cavity structure , the bottom of the cavity structure is provided with several sieve holes 3, and the side wall of the outer liquid retaining sieve plate 7 is also provided with several rows of sieve holes 3 in parallel; There is a row of liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com