Iron ore powder multi-stage suspension state reduction roasting device and method

A roasting device and iron ore powder technology, which is applied in metallurgy and mineral processing fields, can solve problems such as difficulty in obtaining ideal technical and economic indicators, complex mineral composition, and easy ring formation in rotary kilns, etc., with short time to achieve and high heat and mass transfer efficiency , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

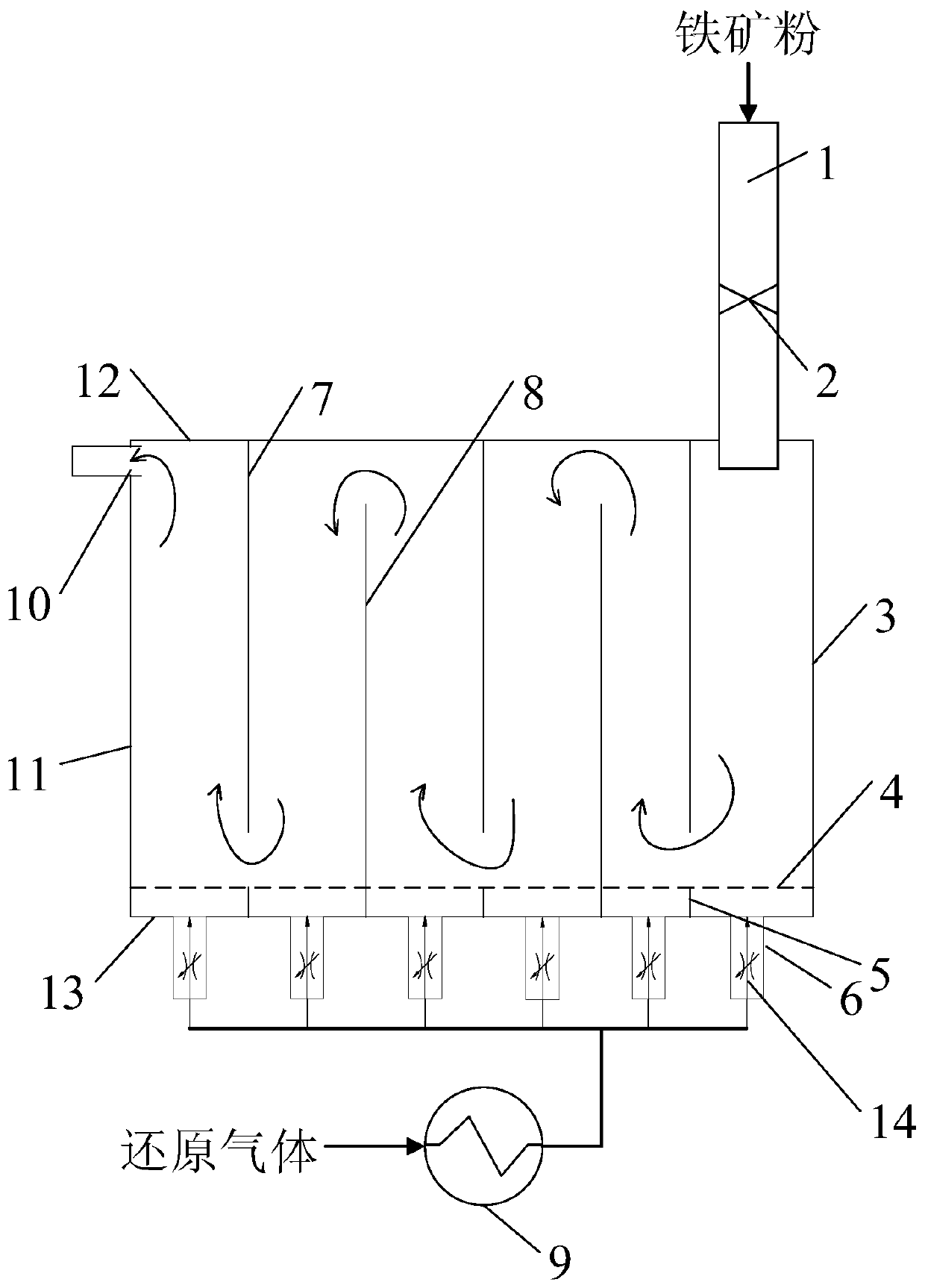

[0033] The structure of iron ore powder multi-stage suspension reduction roasting device is as follows: figure 1 As shown, it includes 6 groups of shell, baffle group, feed inlet and air intake pipe; the shell includes shell side plate, shell front plate 3, shell rear end plate 11, shell bottom plate 13 and shell top plate 12;

[0034] The top of the front end of the casing is provided with a feed port to communicate with the feed pipe 1, and the feed pipe 1 is provided with a flap valve 2;

[0035] A discharge port 10 is provided above the rear end of the casing;

[0036] The baffle group is composed of three upper baffles 7 and two lower baffles 8, and a lower baffle 8 is arranged between two adjacent upper baffles 7, and the baffle group connects the front end plate 3 of the shell and the rear end plate of the shell The space between 11 is evenly divided into 6 reaction chambers;

[0037] The bottom edge of each upper baffle plate 7 is opposite to the top edge of a suppor...

Embodiment 2

[0053] Device structure is the same as embodiment 1, and difference is:

[0054] The baffle group consists of 4 upper baffles and 3 lower baffles, and the baffle group divides the space between the front end plate of the housing and the rear end plate of the housing into 8 reaction chambers on average;

[0055] The iron grade of iron ore powder used is TFe 62.22%, containing FeO 0.26% by mass percentage, SiO 2 3.53%, Al 2 o 3 4.69%, CaO 0.07%, MgO 2.38%, P 0.07%, S 0.02%, particle size ≤ 0.8mm, of which the part with a particle size of -0.074mm accounts for 85% of the total mass;

[0056] Method is with embodiment 1, and difference is:

[0057] (1) The reducing gas is heated to 900°C by a gas heater; the volume percentage of nitrogen in the reducing gas is 40%;

[0058] (2) The residence time of the iron ore powder from the feed port to the discharge port is 20min, and the temperature of the iron ore powder for reduction reaction is 850°C; the ratio of the volume flow rat...

Embodiment 3

[0060] Device structure is the same as embodiment 1, and difference is:

[0061] The baffle group consists of 5 upper baffles and 4 lower baffles, and the baffle group divides the space between the front end plate of the housing and the rear end plate of the housing into 10 reaction chambers on average;

[0062] The iron grade of iron ore powder used is TFe 65.77%, containing FeO 0.78% by mass percentage, SiO 2 6.78%, Al 2 o 3 0.32%, CaO 1.11%, MgO 2.54%, P 0.07%, S 0.02%, particle size ≤ 0.8mm, of which the particle size is -0.074mm accounts for 70% of the total mass;

[0063] Method is with embodiment 1, and difference is:

[0064] (1) The reducing gas is heated to 750° C. by a gas heater; the reducing gas is a mixed gas composed of hydrogen, carbon monoxide and nitrogen, wherein the volume percentage of nitrogen is 40%, and the volume percentage of hydrogen is 40%;

[0065] (2) The residence time of the iron ore powder from the feed port to the discharge port is 40min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com