Kesterite structure cu2fesns4 powder material and its liquid phase preparation method

A technology of kesterite structure and powder, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of few reports, and achieve the effect of low cost, short reaction time and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

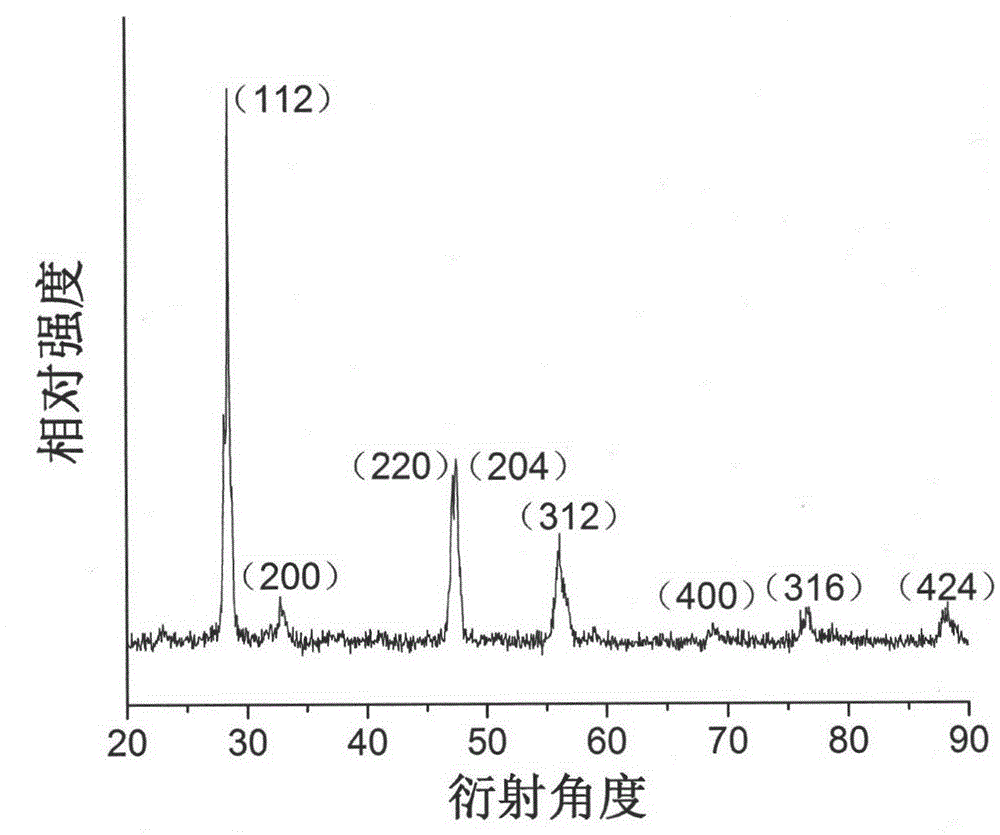

[0028] Weigh 4mmolCuCl 2 2H 2 O, 2mmolSnCl 4 ·5H 2 O, 2 mmol FeCl 3 ·6H 2 0, 8mmol thiourea, put into a three-necked round-bottomed flask, add 30ml of triethylenetetramine, pass into nitrogen as protective gas, place the three-necked round-bottomed flask in a constant temperature oil bath and heat it to 230°C, and keep it for 3 hours, Then it was naturally cooled to room temperature, washed three times with anhydrous ethanol and ionized water successively, then filtered, and dried in a drying oven at 60° C. for 6 h to obtain a black solid. The Cu synthesized in this embodiment 2 FeSnS 4 The XRD energy spectrum of the sample is as follows figure 1 shown. It can be seen from the figure that its diffraction peaks are consistent with those of Cu with kesterite structure. 2 FeSnS 4 The standard card (JCPDSNo44-1476) matches very well, the three main peaks correspond to (112), (220), (204) crystal planes, and its secondary diffraction peaks are (200), (312), (400) , (316)...

Embodiment 2

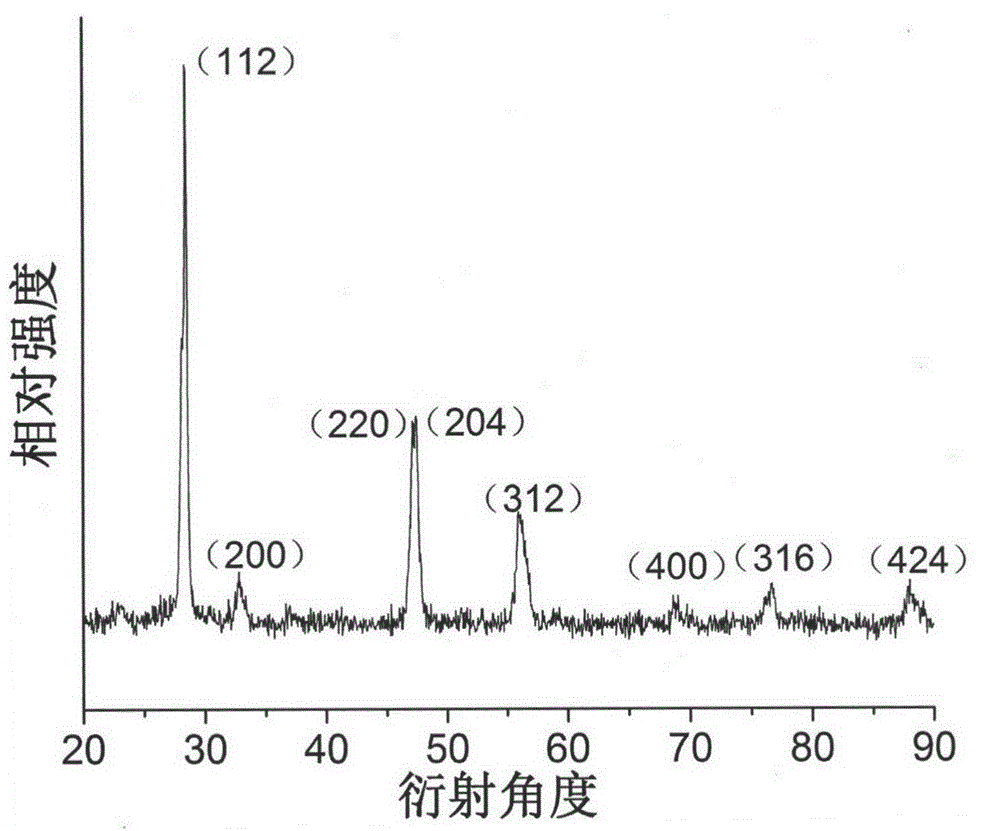

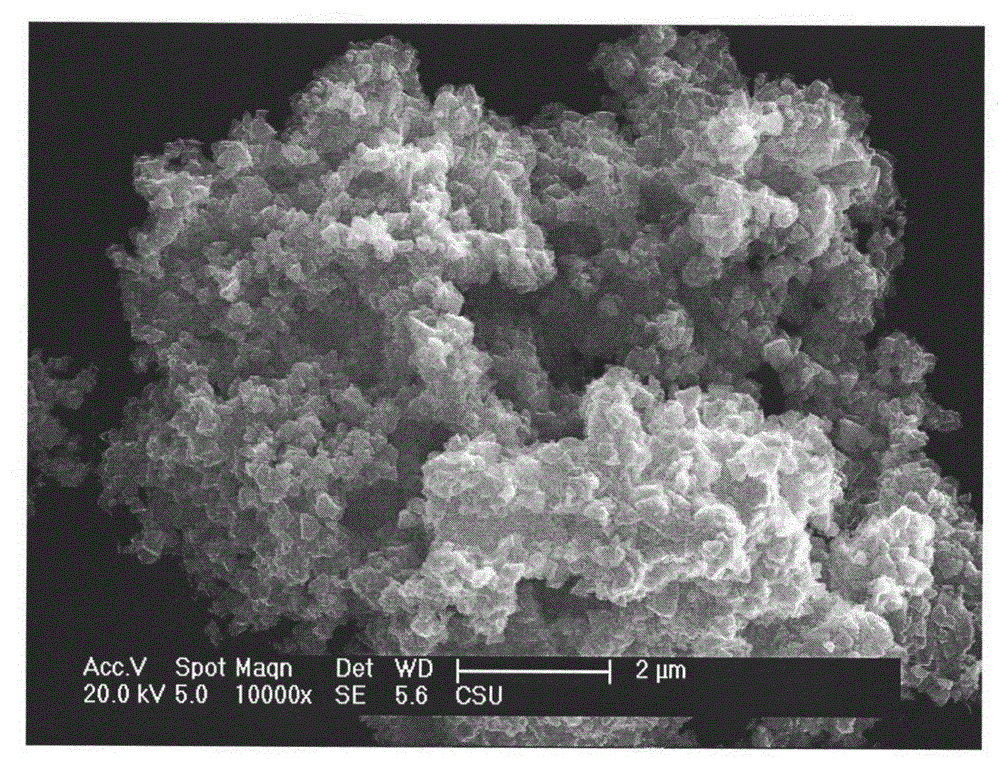

[0030] Weigh 4mmolCuCl 2 2H 2 O, 2mmolSnCl 4 ·5H 2 O, 2 mmol FeCl 3 ·6H 2 0, 8mmol thiourea, put into a three-necked round-bottomed flask, add 15 mL each of mixed solvent ethylene glycol and triethylenetetramine, feed in nitrogen as protective gas, place the three-necked round-bottomed flask in a constant temperature oil bath and heat to 230°C, and kept for 3 hours, then naturally cooled to room temperature, washed with absolute ethanol and deionized water three times in sequence, then filtered, and dried in a drying oven at 60° C. for 3 hours to obtain a black solid. The Cu synthesized in this embodiment 2 FeSnS 4 The XRD energy spectrum and SEM image of the sample are as follows figure 2 , image 3 shown. It can be seen from the SEM image that the obtained sample is in the shape of particles, the size is about 100-300nm, the yield is high, and the distribution is relatively uniform.

Embodiment 3

[0032] Weigh 4mmolCuCl 2 2H 2 O, 2mmolSnCl 4 ·5H 2 O, 2 mmol FeCl 3 ·6H 20, 8mmol thiourea, put into a three-necked round-bottomed flask, add 15 mL each of mixed solvent ethylene glycol and triethylenetetramine, feed in nitrogen as protective gas, place the three-necked round-bottomed flask in a constant temperature oil bath and heat to 200°C, and kept for 3 hours, then naturally cooled to room temperature, washed with absolute ethanol and deionized water three times in sequence, then filtered, and dried in a drying oven at 60°C for 2 hours to obtain a black solid. The Cu synthesized in this embodiment 2 FeSnS 4 The XRD energy spectrum of the sample is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com