Preparation method for temperature-sensitive core-shell structured microspheres and application thereof in separation

A molecular weight, telechelic polymer technology, applied in the field of temperature-sensitive core-shell structure microspheres, can solve the problems of low monomer grafting rate, difficult control of molecular weight core-shell structure, high consumption of raw materials, etc. Good separation effect and complete reaction degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

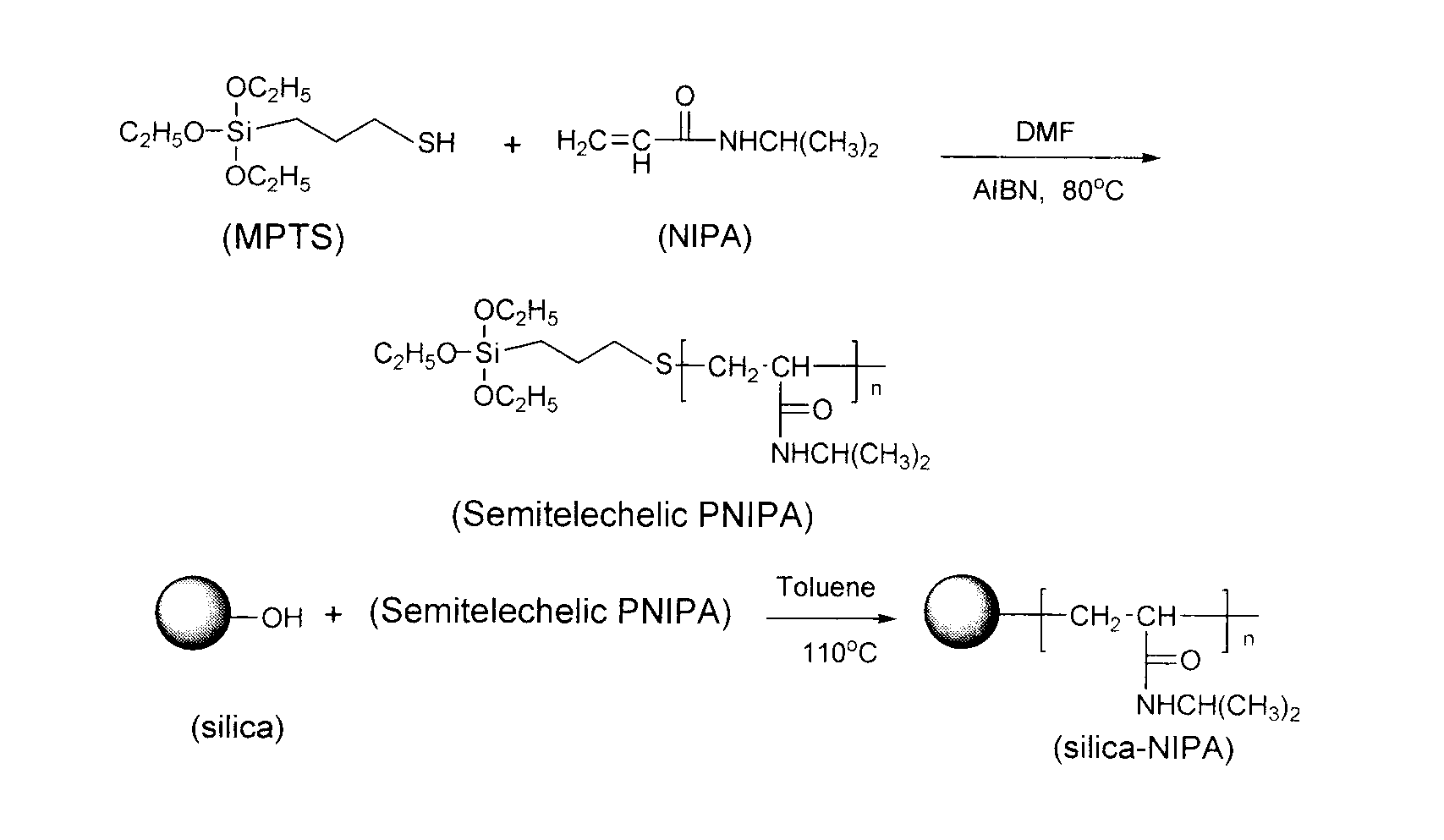

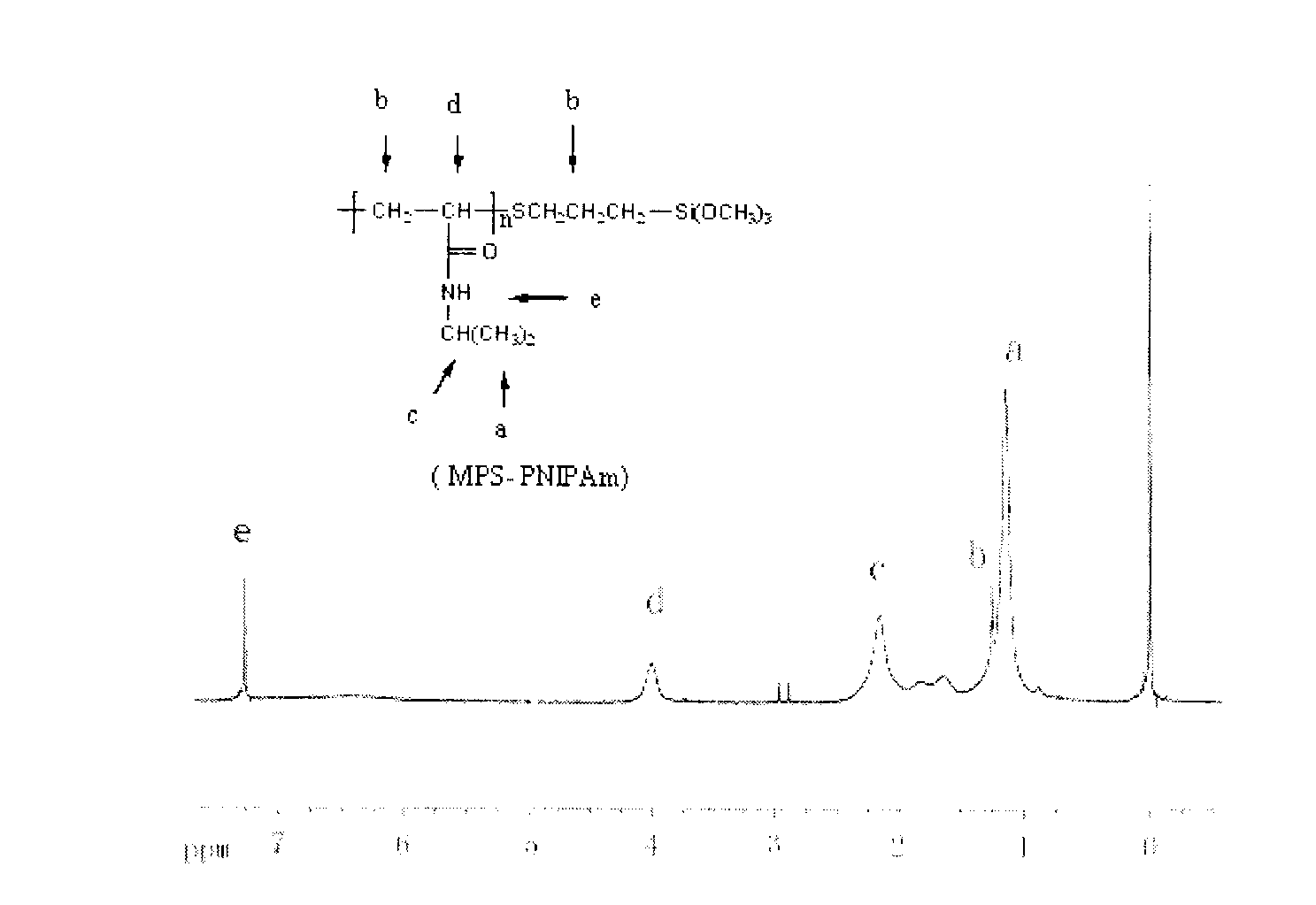

[0017] like figure 1 As shown, N-isopropylacrylamide is a reactive monomer, azobisisobutyronitrile is used as an initiator, and mercaptopropyltriethoxysilane is dissolved in DMF as a molecular weight regulator (see Table 1 for specific dosage) , the above mixture was reacted at 70° C. for 10 h under the protection of nitrogen, and the product was rotary evaporated at 70° C. After concentration, the polymer was precipitated with diethyl ether as a precipitating agent. The polymer was further purified by repeated dissolution-sedimentation with THF and ether.

[0018] Table 1 Synthetic formula and results of semi-telechelic polymer

[0019]

Embodiment 2

[0021] Add the above-mentioned macromolecular product and silica gel particles into toluene solvent, add a certain amount of pyridine as a reaction auxiliary agent, and mix well. Under the protection of nitrogen, react at 110°C for 10h. The product is centrifugally settled, and the obtained composite particles are repeatedly extracted with deionized water to remove ungrafted macromolecular aggregates, and then repeatedly washed with methanol and ultrapure water in sequence. The product was dried under vacuum at room temperature to obtain a white powdery solid.

[0022] Table 2 The synthetic grafting ratio of the composites as a function of time

[0023]

Embodiment 3

[0025] Surface modified silica gel at 350kg / cm 2 Under the pressure of 100%, the mixed solvent of methanol and water (1:1) was filled into a stainless steel column (150mm × 4.6mm) as a homogenizer, and then equilibrated with deionized water for 4h; the steel column was connected to the HPLC system (Waters 1525 Binany HPLC Pump, Waters 2996 Potodiode Array Detector, Waters 717Plus Autosampler). A mixture of three aqueous solutions of naphthalene derivatives was used as a solute, a mixture of water / methanol in a volume ratio of 9:1 was used as a mobile phase, and chromatographic separation was performed at a flow rate of 1.0 mL / min. The concentrations of the three naphthalene derivatives were 4 mg / mL for naphthalene acetic acid; 6 mg / mL for naphthylamine; and 5.7 mg / mL for naphthol. Detected at UV 215nm, controlled different temperatures to observe the elution behavior of the three substances. The temperature is controlled by a column thermostat, and its temperature fluctuatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com