Preparation method of macromolecule ultraviolet radiation absorbent

A polymerization and ultraviolet technology, which is applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of easy migration and loss, improve the resistance to ultraviolet light aging, the preparation method is simple and feasible, and the post-processing is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

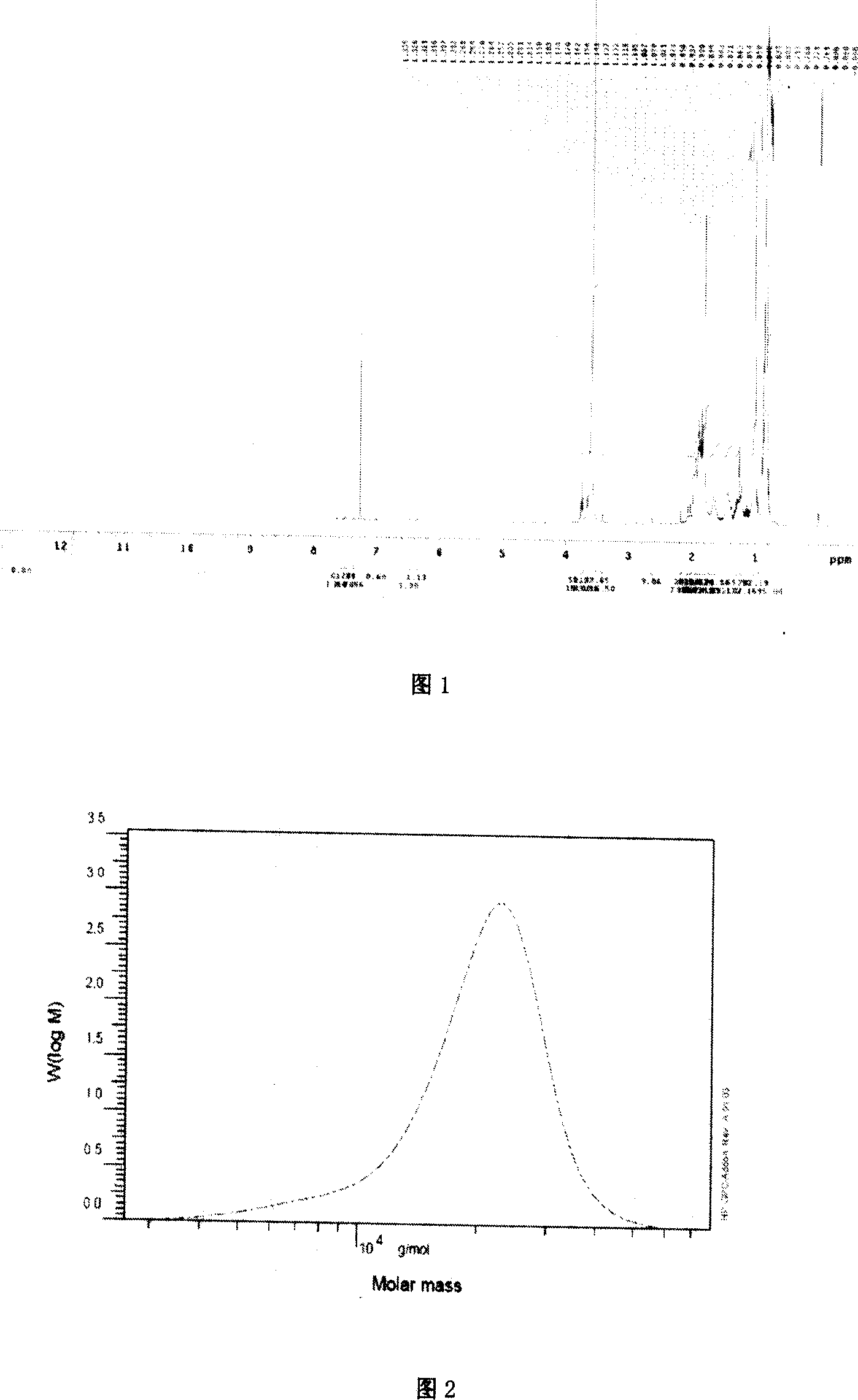

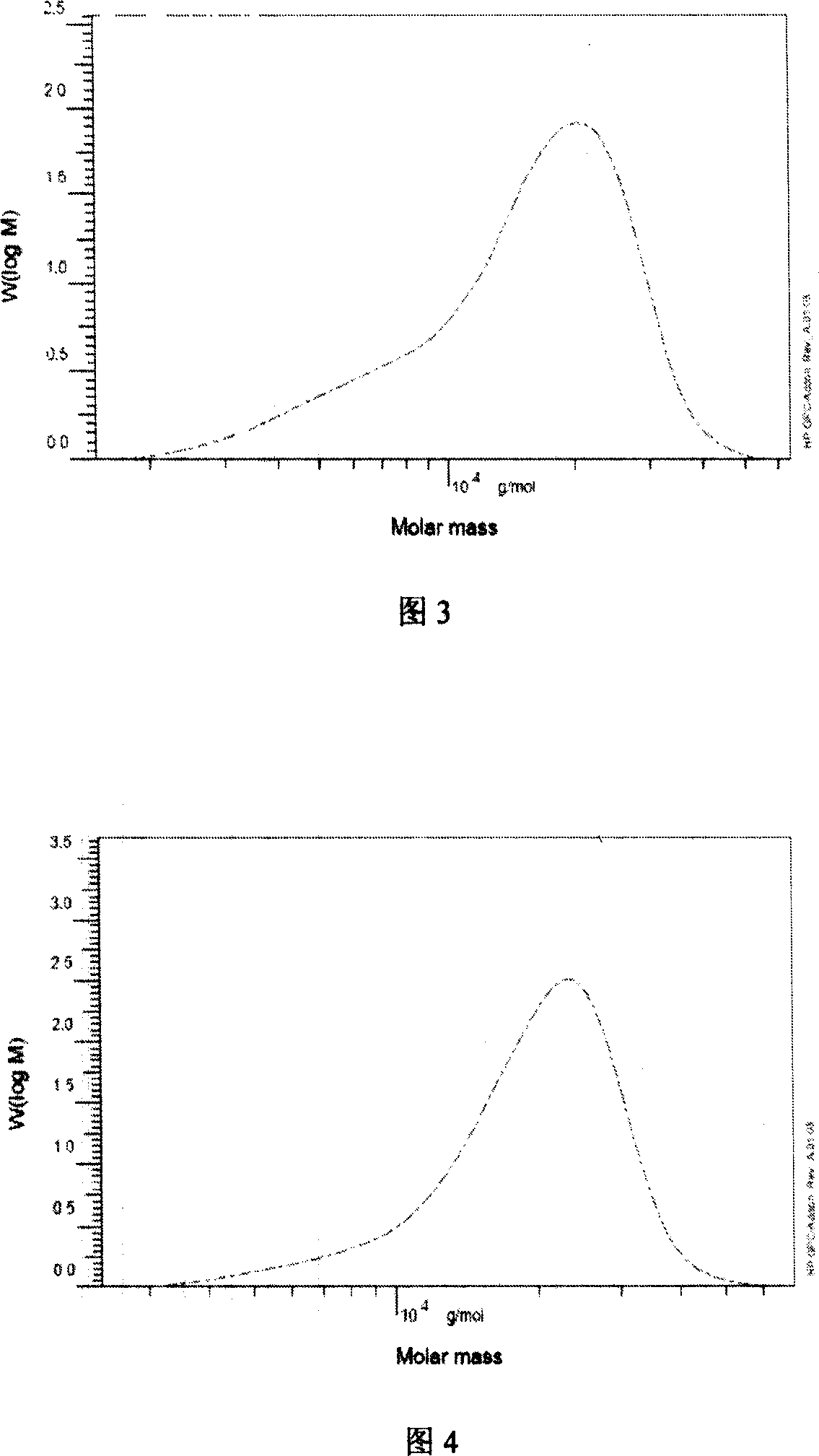

[0032] First, weigh 20 parts of MMA, 80 parts of xylene, 0.1 part of AIBN, 0.05 part of CuBr by weight 2and 0.1 part of TMEDA, all added into a sealed reaction bottle, stirred at room temperature for 1 hour, then passed high-purity argon, vacuumed, and evacuated repeatedly three times, put it in a water bath at 80°C for 3 hours, stopped the reaction, and precipitated and purified , drying to obtain macromolecules. The obtained polymer product is dissolved in a good solvent, configured into a dilute solution, and refluxed with an equimolar ratio of 2,4-dihydroxybenzophenone (UV-0) small-molecule ultraviolet absorber under the catalytic action of a catalyst After 30 hours, a polymerized ultraviolet absorber with a narrow molecular weight distribution can be prepared.

Embodiment 2

[0034] First, weigh 30 parts of MBA, 70 parts of toluene, 0.15 parts of BPO, 0.075 parts of CuCl 2 and 0.15 parts of bpy, all added into a sealed reaction bottle, stirred at room temperature for 3 hours, then passed high-purity argon, evacuated, and repeatedly evacuated three times, put it in a 90°C water bath for 4 hours to stop the reaction, and precipitated and purified , drying to obtain macromolecules. Dissolve the obtained macromolecule product in a good solvent, configure it into a dilute solution, and react with 2,4-dihydroxybenzophenone (UV-0) small-molecule ultraviolet absorber in an equimolar ratio under the catalysis of the catalyst After 50 hours, a polymerized ultraviolet absorber with a narrow molecular weight distribution can be prepared.

Embodiment 3

[0036] First, weigh 40 parts of St, 60 parts of xylene, 0.2 part of benzyl bromide, 0.1 part of CuBr and 0.2 part of dNbpy in parts by weight, add them all into a sealed reaction bottle, stir at room temperature for 5 hours, and then pass high-purity argon to pump Vacuum, repeated evacuation three times, put into 110 ℃ water bath to react for 5 hours and then stop the reaction, after precipitation, purification and drying, the polymer was obtained. The obtained polymer product is dissolved in a good solvent, configured into a dilute solution, and refluxed with an equimolar ratio of 2,4-dihydroxybenzophenone (UV-0) small-molecule ultraviolet absorber under the catalytic action of a catalyst After 70 hours, a polymerized ultraviolet absorber with a narrow molecular weight distribution can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com