Ultrahigh-molecular-weight atactic polypropylene resin capable of being used for 3D printing, and preparation method and application thereof

An ultra-high molecular weight, random polypropylene technology, applied in the field of ultra-high molecular weight random polypropylene resin and its preparation, can solve the problems of high energy consumption, application limitation, poor melt fluidity, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] 1. Preparation of supported metallocene catalysts

[0077] The supported metallocene catalyst used in the present invention is selected from SiO 2 A metallocene catalyst as a carrier, characterized in that the particle size of the catalyst particles is 0.1 to 30 μm, prepared by the following method:

[0078] Take 5.0g of SiO 2 The carrier (particle size 1-30 μm) was placed in a two-neck flask filled with argon and mechanically stirred, then 30 mL of toluene solution was added, the temperature was lowered to 0 °C, 20 mL of MAO solution (concentration was 1.4 mol / L) was slowly added, and continued After stirring the reaction for 12h, add 3.7g metallocene compound (C 2 h 4 ) 2 Flu(2-CH 3 -5,6-Cyclopentyl-Ind)Hf(CH 3 ) 2 , Continue to stir the reaction for 3h. The reaction product was washed three times with toluene and hexane respectively, and dried in vacuum to obtain a supported metallocene catalyst A. The particle diameter of the catalyst is 1-30 μm.

[0079] ...

Embodiment 1

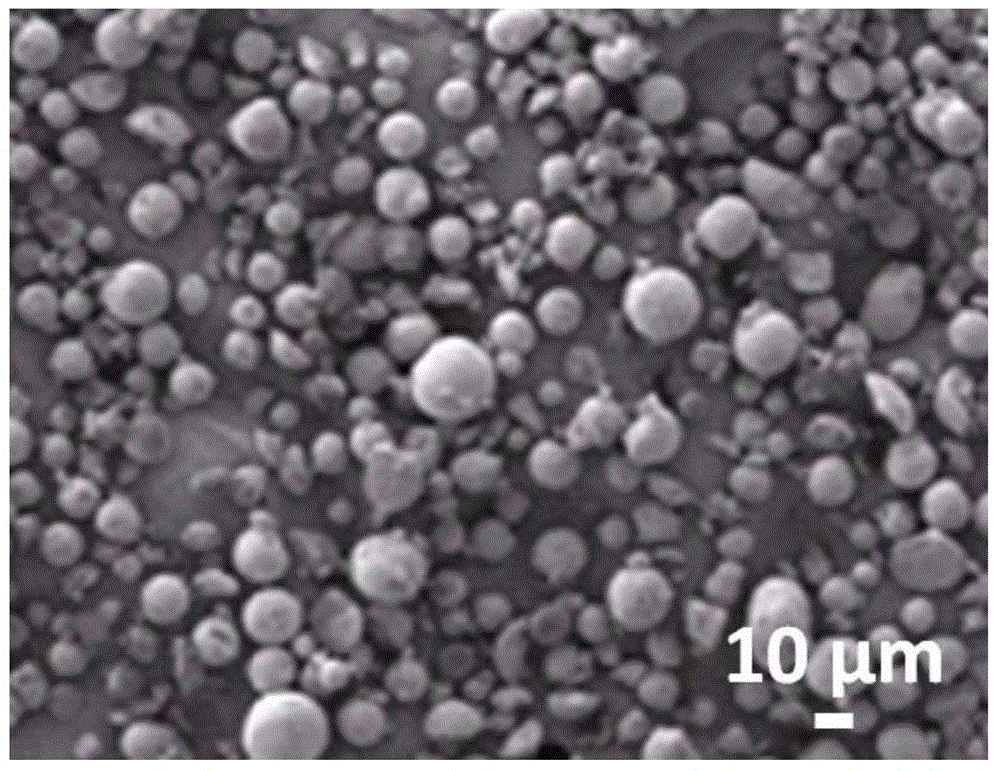

[0088] Add 200g liquid propylene, 0.2ml (CPh 3 )[B(C 6 f 5 ) 4 ] (concentration is 1.0mol / L) and 100mg above-mentioned prepared catalyst A, carry out polymerization at 0 ℃, after reacting for 30 minutes, vent the residual gas in the polymerization reactor, collect the polymerization product, obtain 35g white ultrahigh molecular weight after drying Atactic polypropylene resin powder.

[0089] The molecular weight of the obtained polypropylene resin is 4.90×10 6 g / mol, [mmmm] content is 17%, and the particle size of polymer particles is 100-400 μm.

Embodiment 2

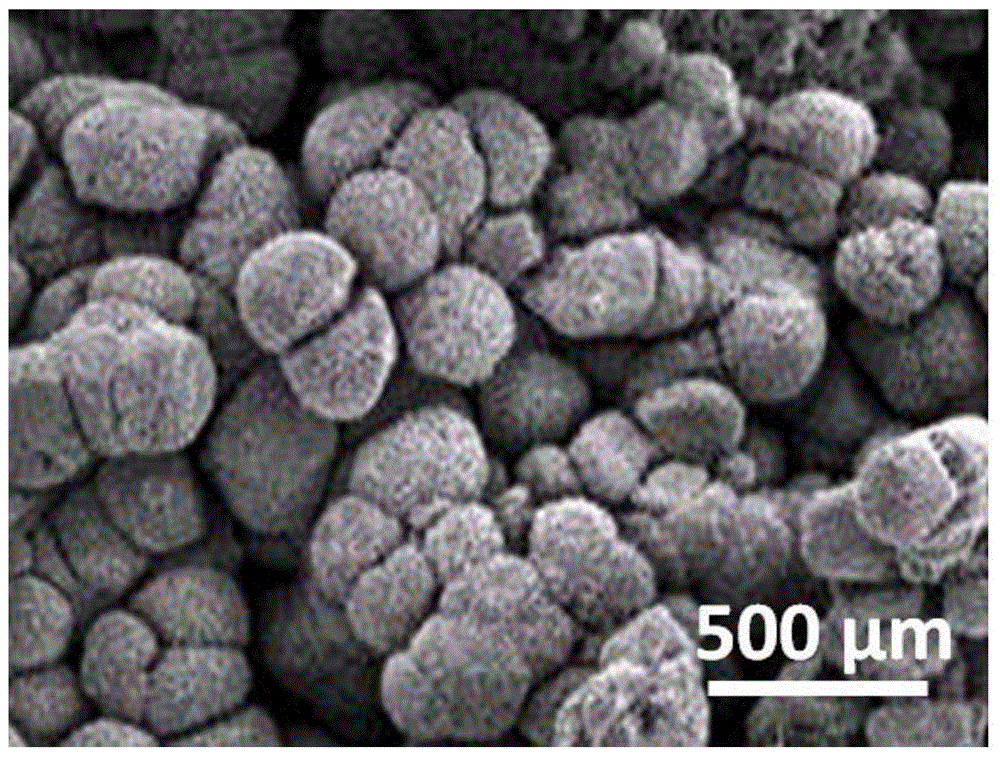

[0091] Add 300g liquid propylene, 0.2ml (CPh 3 )[B(C 6 f 5 ) 4 ] (concentration is 1.0mol / L) and 100mg above-mentioned catalyst A of preparation, carry out polymerization at 20 ℃, after reacting for 30 minutes, empty the residual gas in the polymerization reactor, collect polymerization product, obtain 140g white ultrahigh molecular weight after drying Atactic polypropylene resin powder.

[0092] The molecular weight of the obtained polypropylene resin is 1.60×10 6 g / mol, the [mmmm] content is 24%, and the particle size of the polymer particles is 200-600 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com