Method for preparing double-peak or broad-peak polyethylene with adjustable molecular weight

A technology of molecular weight and polyethylene, applied in the field of preparation of polyethylene with adjustable molecular weight bimodal or broad-peak distribution, can solve the problems of high catalyst requirements, difficult to control product quality uniformity, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

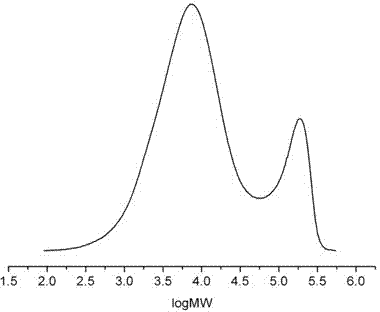

[0019] Firstly, the reactor was replaced with nitrogen three times at a high temperature of 100°C, and then replaced with ethylene three times. Then, 250 ml of anhydrous and oxygen-free toluene was added under an ethylene atmosphere, and stirring was started. The stirring rate was 600 rpm, and the temperature was controlled at At 25 °C, the pressure was controlled at 0.1 MPa, 10 mmol of methylaluminoxane was added, and 5 μmol of bis(3-methylsalicylidene-pentafluorophenylphenylimine) titanium dichloride was added for polymerization. When the reaction lasted for 1 minute, 900 μmol of diethylzinc was added, the reaction was continued for 15 minutes, and 4 ml of acidified ethanol was added to terminate the reaction. GPC method measures the molecular weight distribution of sample, and the results are shown in attached table 1.

Embodiment 2

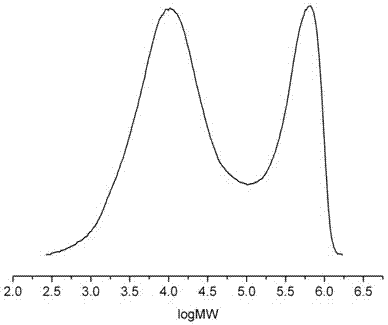

[0021] Firstly, the reactor was replaced with nitrogen three times at a high temperature of 100°C, and then replaced with ethylene three times. Then, 250 ml of anhydrous and oxygen-free toluene was added under an ethylene atmosphere, and stirring was started. The stirring rate was 600 rpm, and the temperature was controlled at At 25 °C, the pressure was controlled at 0.1 MPa, 10 mmol of methylaluminoxane was added, and 5 μmol of bis(3-methylsalicylidene-pentafluorophenylphenylimine) titanium dichloride was added for polymerization. When the reaction lasted for 5 minutes, 900 μmol of diethylzinc was added, the reaction was continued for 15 minutes, and 4 ml of acidified ethanol was added to terminate the reaction. GPC method measures the molecular weight distribution of sample, and the results are shown in attached table 1.

Embodiment 3

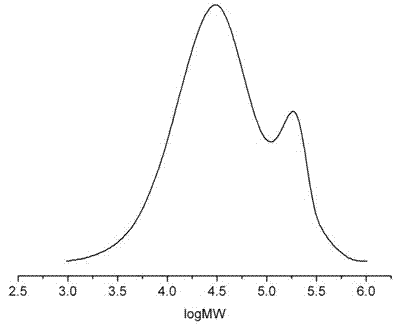

[0023] Firstly, the reactor was replaced with nitrogen three times at a high temperature of 100°C, and then replaced with ethylene three times. Then, 250 ml of anhydrous and oxygen-free toluene was added under an ethylene atmosphere, and stirring was started. The stirring rate was 600 rpm, and the temperature was controlled at At 25 °C, the pressure was controlled at 0.1 MPa, 10 mmol of methylaluminoxane was added, and 5 μmol of bis(3-methylsalicylidene-pentafluorophenylphenylimine) titanium dichloride was added for polymerization. When the reaction lasted for 1 minute, 450 μmol of diethylzinc was added, the reaction was continued for 15 minutes, and 6 ml of acidified ethanol was added to terminate the reaction. GPC method measures the molecular weight distribution of sample, and the results are shown in attached table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com