Metal composite catalyst for alkene polymerization and preparation method thereof

A technology for metal composite and olefin polymerization, applied in the field of metal composite catalysts and their preparation, can solve the problems of not being able to give full play to their advantages, and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

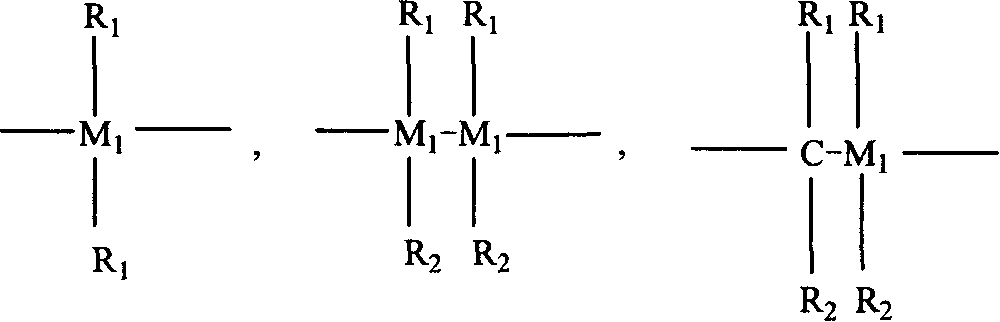

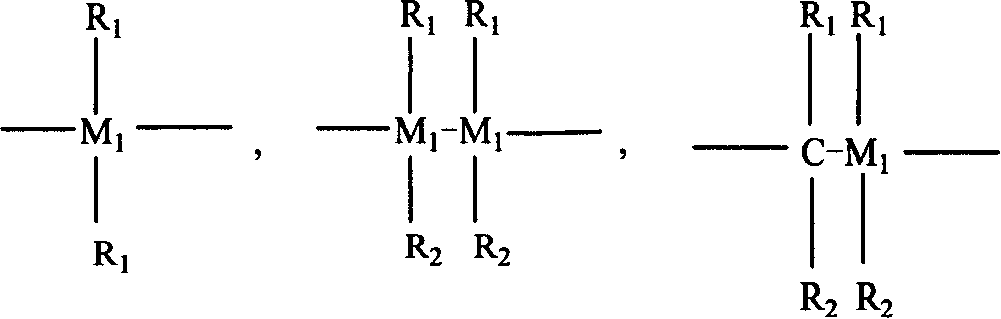

Image

Examples

preparation example Construction

[0036] Part I Preparation of Metal Composite Catalysts

[0037] In the present invention, Me=methyl, Ph=phenyl, Cp=cyclopentadienyl, Ind=indenyl, H 4 Ind=4,5,6,7-tetrahydroindenyl, Flu=fluorenyl, Naph=naphthyl, rac=racemate

Embodiment 1

[0038] Embodiment 1, the preparation of metal composite catalyst

[0039] 1. Spherical MgCl 2 Preparation of vector

[0040] 0.25mol of anhydrous MgCl 2 Add 0.5mol of absolute ethanol, 390ml of white vaseline oil, and 10ml of silicone oil into the autoclave, heat to 80°C and stir to obtain a uniform solution, blow nitrogen to raise the pressure to 1MPa, open the valve, and let the mixture in the kettle pass through 1.2mm, length 3.5 M thin tube, sprayed into 2.5L kerosene, washed 5 times with hexane, and dried at room temperature.

[0041] 2. Preparation of spherical Ziegler-Natta catalyst

[0042] Take MgCl 2 Add 2g of the carrier into the preparation bottle, blow in argon after vacuum, then add 100ml of TiCl at -20°C 4 , when the temperature was raised to 60°C with stirring, 0.5 g of 9,9-bis(methoxymethyl)fluorene (BMF) was added, and the mixture was stirred for 2 hours. Vacuum filter, add 100ml TiCl 4 , heated up to 120°C, and treated for 2 hours. Washed 6 times wit...

Embodiment 2

[0045] Embodiment 2, the preparation of metal composite catalyst

[0046] 1. Spherical MgCl 2 Preparation of vector

[0047] 0.25mol of anhydrous MgCl 2 Add 1.25mol of propanol into the autoclave, heat to 150°C and stir to obtain a homogeneous solution, pass nitrogen to raise the pressure to 1MPa, open the valve, let the mixture in the kettle pass through a 1.2mm, 3.5m long thin tube, above 100°C In a vacuum drying container, the powder was washed 5 times with heptane and dried at room temperature.

[0048] 2. Preparation of spherical Ziegler-Natta catalyst

[0049] Take MgCl 2 Add 2g of the carrier into the preparation bottle, blow in argon after vacuum, then add 100ml of TiCl at 0°C 4 , after stirring and raising the temperature to 80° C., 0.5 g of BMF was added. The temperature was raised to 130° C., and the mixture was stirred for 2 hours. Vacuum filter, add 100ml TiCl 4 , heated to 130° C., treated for 2 hours, washed 6 times with hexane, and dried in vacuum to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com