Technology for treating oil extraction-generated waste water

A technology for oil extraction wastewater and treatment process, which is applied in mining wastewater treatment, flotation water/sewage treatment, adsorption water/sewage treatment, etc. increase and other problems, to achieve the effects of low investment and production costs, accelerated flotation separation speed, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

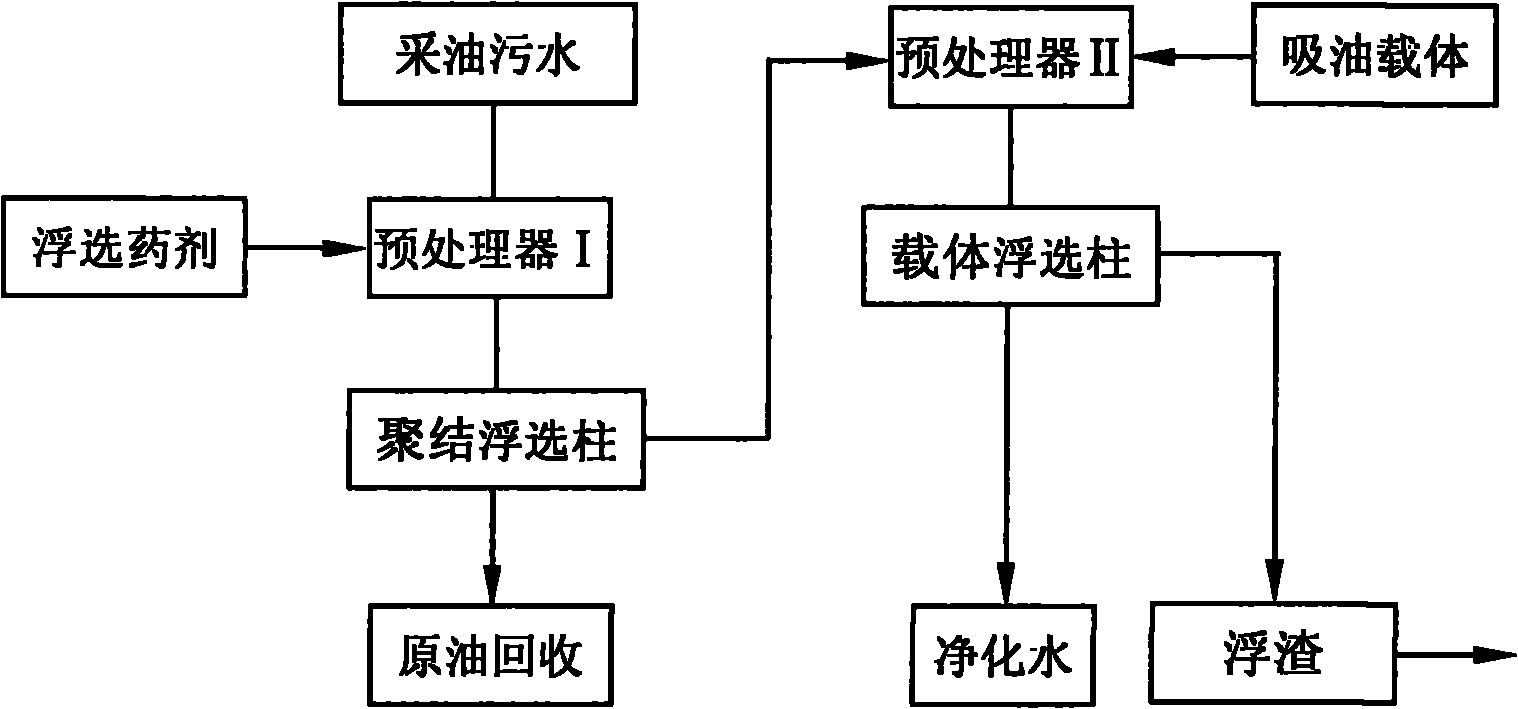

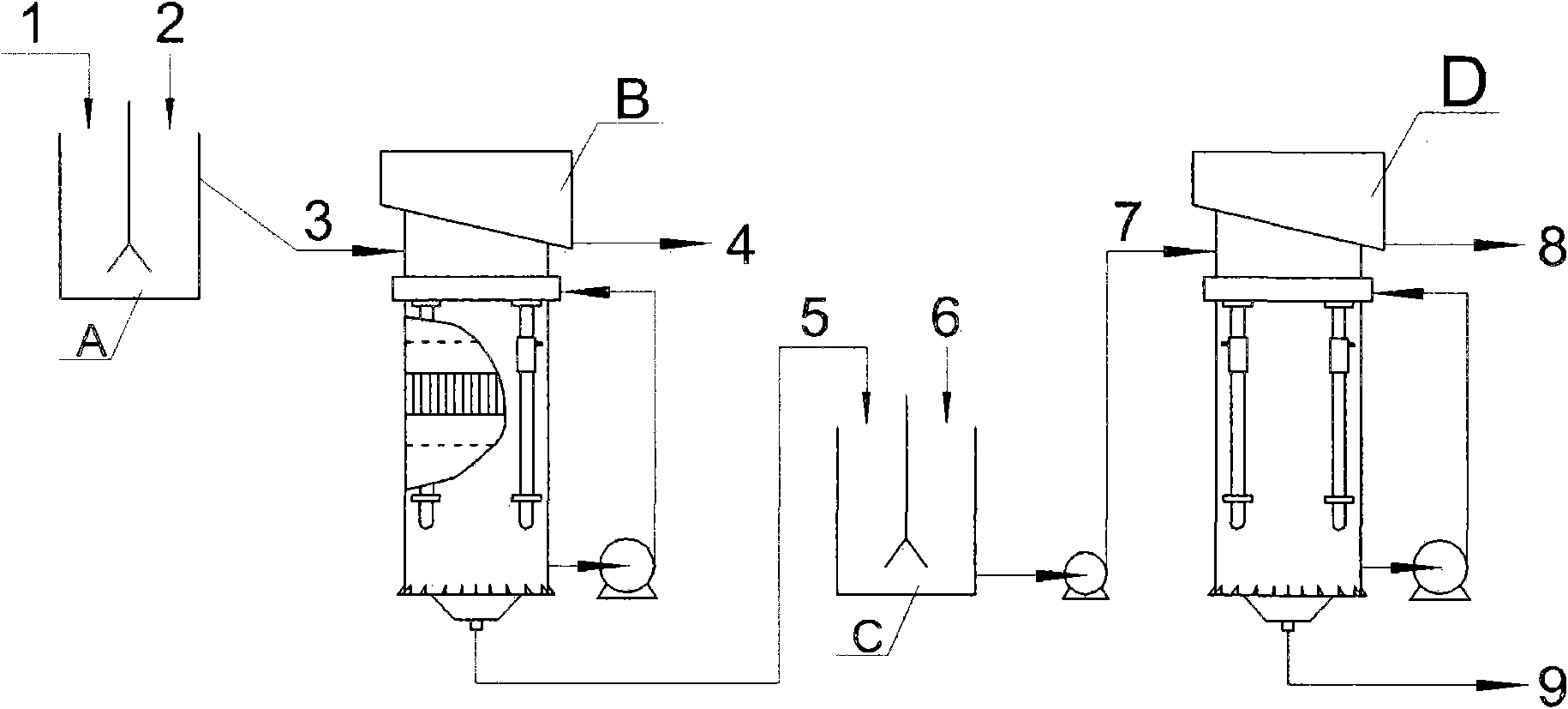

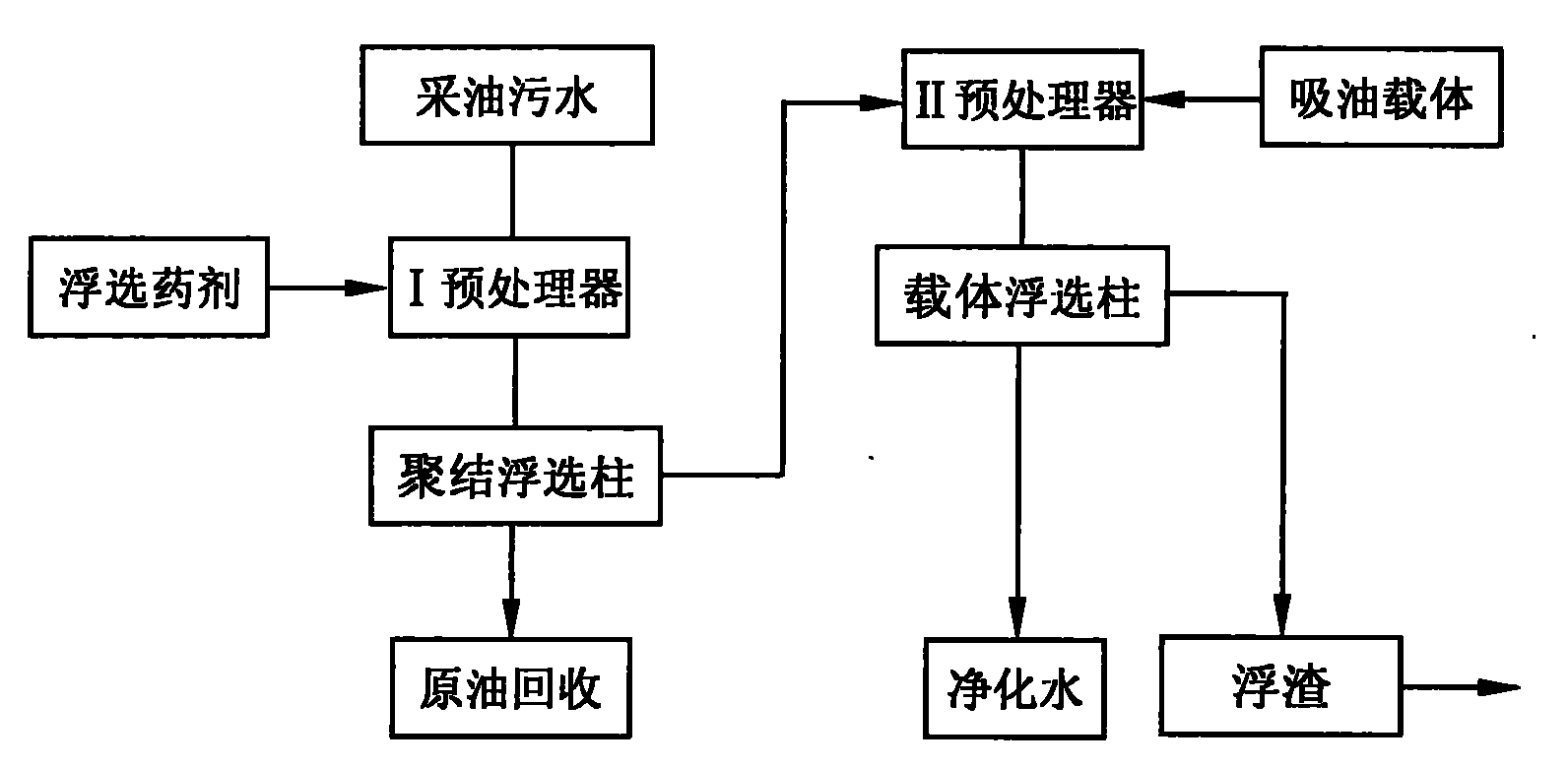

[0016] The treatment process of the oil extraction sewage of the present invention is mainly composed of two parts: coalescing flotation column B flotation and carrier flotation column D flotation. Coalescing flotation column B and carrier flotation column D both adopt cyclone-static microbubble flotation column. First, the oil production sewage 1 and the foaming agent 2 are sent into the I preprocessor A for agitation pretreatment. The foaming agent includes alcohols, ethers, carboxylic acids and their soaps, alkylsulfonic acids and their soaps for foaming The addition of foaming agent 2 is adjusted according to the 10-20% gas holdup required when the flotation column is running. The pretreated mixed material is fed into the coalescence flotation column B through the feed pipe 3, and is coalesced and separated by flotation through the coalescence flotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com