Alkylaniline carboxylate or sulphonate surfactant

A surfactant and alkyl aniline technology, applied in drilling compositions, chemical instruments and methods, organic chemistry, etc., can solve problems such as damage, achieve low cost, increase oil recovery, and huge economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

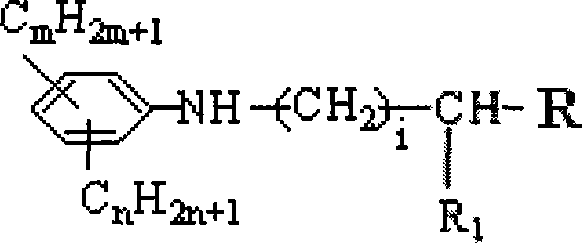

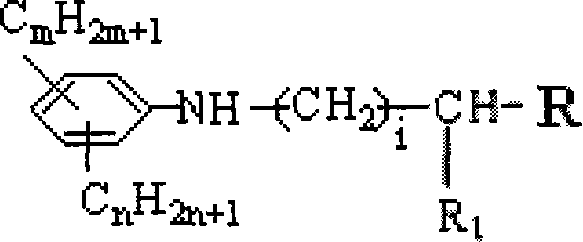

[0032] The carboxylate or sulfonate surfactant of alkylaniline of the present invention is the compound of following general formula:

[0033]

[0034] Among them: m is any positive integer from 1 to 20; n is any positive integer from 0 to 12; i is any positive integer from 0 to 12; R 1 H, -CH 3 Any one of them; R stands for -COOM, -SO 3 M.

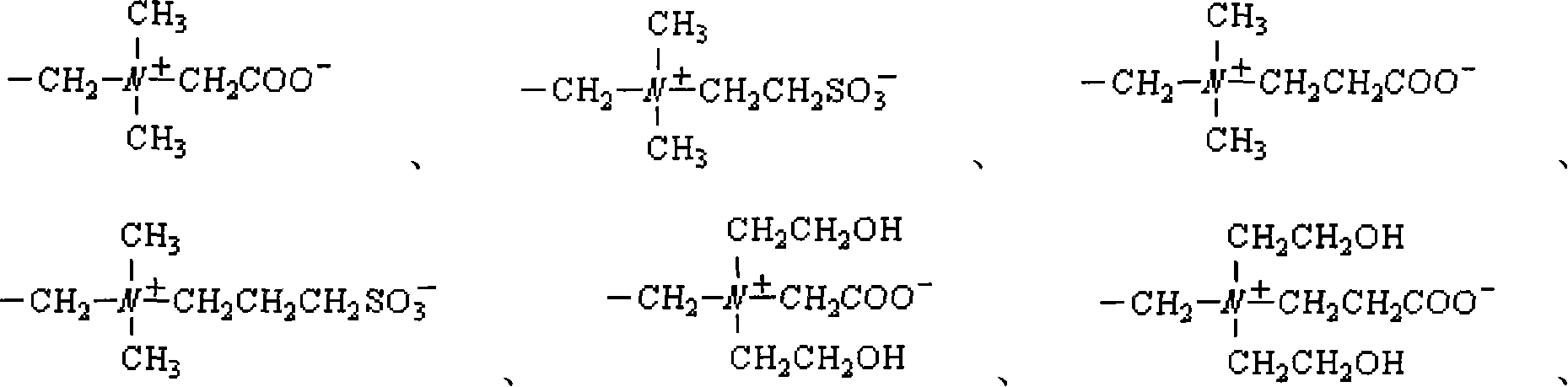

[0035]

[0036] -CH 2 NHCH 2 COOM or -CH 2 NHCH 2 CH 2 COOM; -COOM, -SO above 3 M, -CH 2 NHCH 2 COOM, -CH 2 NHCH 2 CH 2 M in COOM is one of sodium, potassium, monoethanolamine, diethanolamine or triethanolamine.

[0037] Among them, preferably m is any integer of 9 to 18; n is any positive integer of 0 to 4; i is any positive integer of 1 to 3; R 1 for H; R for -SO 3 M or -COOM; M is any one of sodium, potassium, monoethanolamine, and diethanolamine.

[0038] More preferably, m is any integer from 9 to 12; n is any positive integer from 0 to 2; i is any positive integer from 1 to 2; M is sodium or potassium.

[00...

Embodiment 2

[0041] Synthesis of Potassium p-Dodecylaniline Propionate Surfactant

[0042] Add 261g of p-dodecylaniline and 250ml of benzene into a 1000ml three-necked flask equipped with a condenser, a stirrer, and a constant pressure burette. When the temperature rises to 65°C, add 100g of methyl acrylate dropwise, and continue the reaction for 4 hours after the drop is complete. Then raise the temperature to 120°C to remove benzene and excess methyl acrylate.

[0043] In addition, 70 g of potassium hydroxide and 600 g of water were added to a 1000 ml three-necked flask equipped with a condenser, a stirrer, and a constant pressure burette, and the temperature was raised to reflux, and the intermediate product prepared above was added dropwise. After the dropwise addition was completed, the reaction was carried out for 3 hours. The temperature was lowered to 50° C., and 200 g of propanol was added. That is, a surfactant solution containing 20% Li was obtained.

Embodiment 3

[0045] Synthesis of Potassium p-Nonylaniline Undecanoate Surfactant

[0046] Add 219g of p-nonylaniline and 250ml of benzene into a 1000ml three-neck flask equipped with a condenser, agitator, and a constant pressure burette, raise the temperature to 65°C, start adding 240g of methyl undecylenate dropwise, and continue the reaction for 4 hours after the dropwise completion . Heating to remove benzene and excess undecylenic acid methyl ester.

[0047] Add 40 g of potassium hydroxide, 620 g of water, and 240 g of the intermediate product prepared above into a 2000 ml three-neck flask equipped with a condenser, a stirrer, and a constant pressure constant pressure tube, and heat up to reflux for 3 hours of reaction. The temperature was lowered to 50° C., and 300 g of butanol was added to the system. That is, a surfactant solution containing 20% Li was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com