Fleeing sealing sand-prevention ignition method of fireflooding oil extraction

A technology of sand control and fire flooding, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., which can solve the problems of sand production, large and serious gas channeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0028] The present invention proposes an ignition method for blocking channeling and sand prevention in fire flooding oil recovery, and the ignition method comprises the following steps:

[0029] (1) Preheat the oil layer:

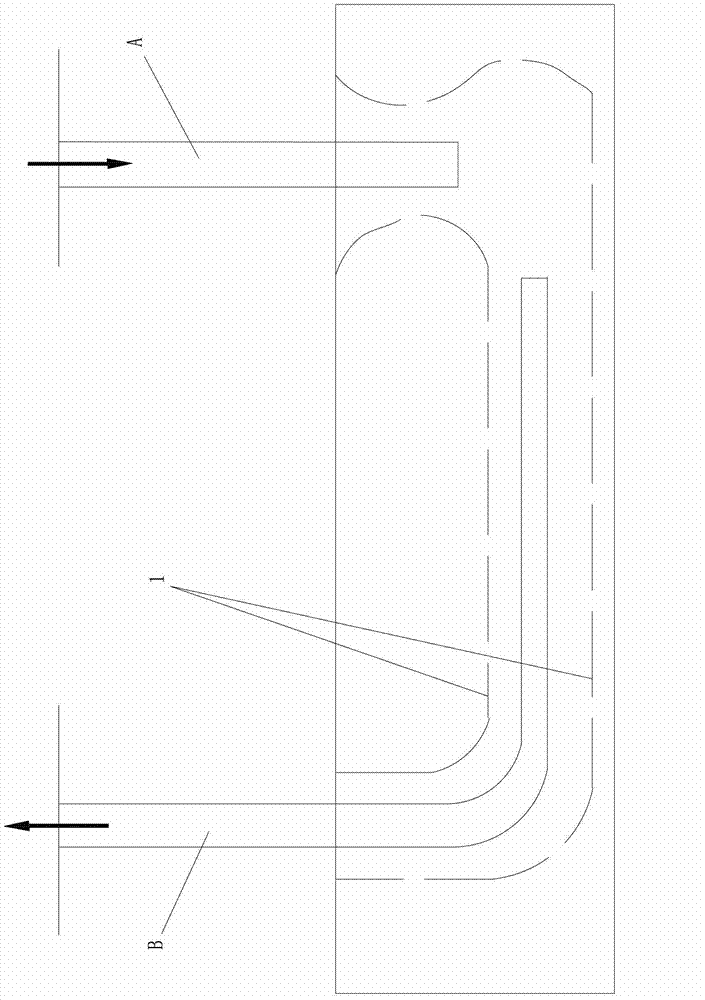

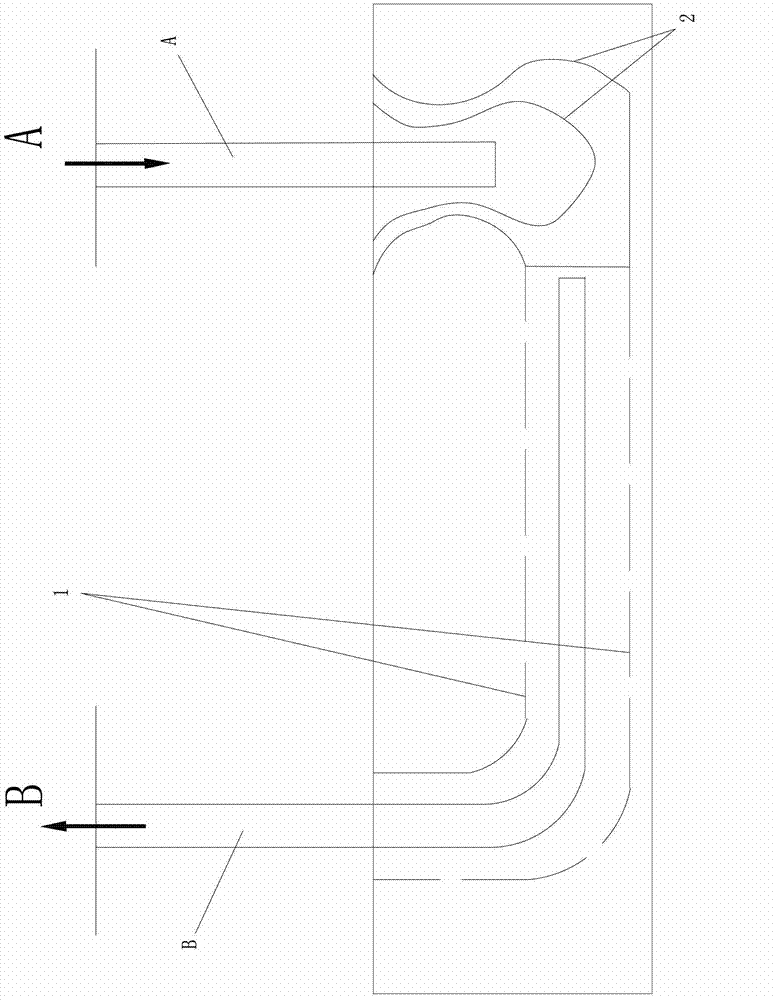

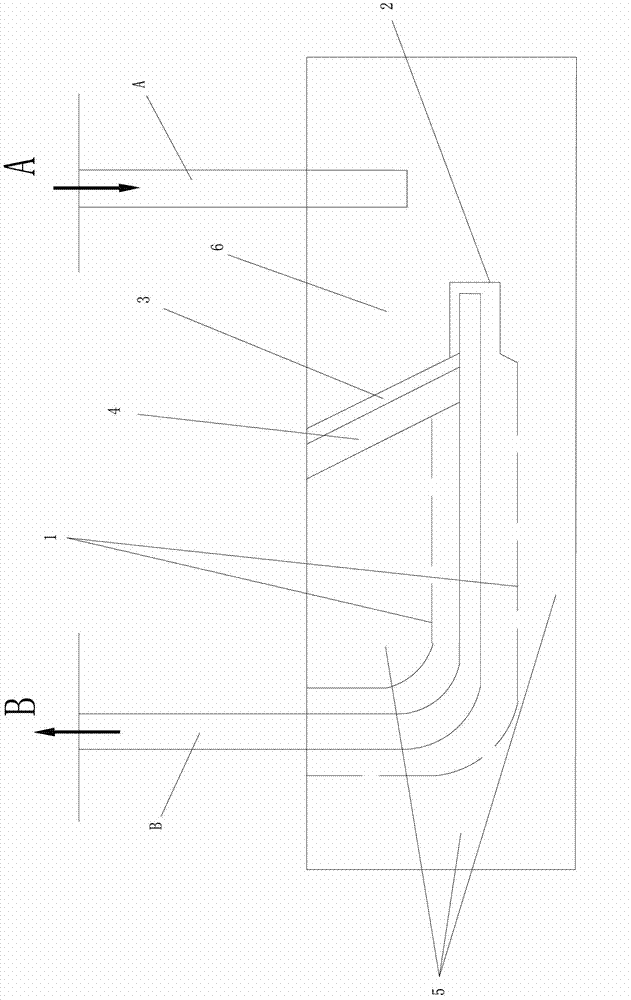

[0030] Such as figure 1 As shown in , inject steam into gas injection well A and horizontal production well B at the same time for preheating, and establish a thermal communication channel between injection well A and horizontal production well B. figure 1 The middle mark 1 is the preheating boundary, and the thermal communication channel is the area trapped by the preheating boundary 1; after preheating, the near-wellbore temperature of gas injection well A is >200°C;

[0031] The horizontal and vertical d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com